Auxiliary winding device

An auxiliary device and winding technology, which is applied in the directions of transportation and packaging, transportation of filamentous materials, and processing of thin materials, etc., can solve the problems of unsatisfactory, unusable, and lack of cotton thread tension devices, etc., and achieves simple structure, Quick installation and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

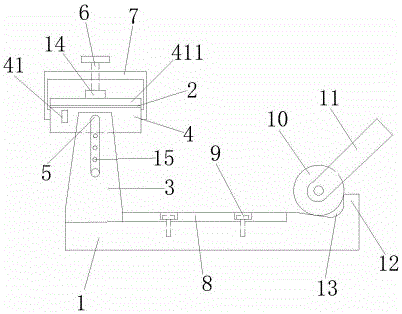

[0010] Below in conjunction with accompanying drawing, the present invention will be further described:

[0011] A winding auxiliary device, including a clamping plate 1 and a threading pipe row 2, one end of the clamping plate 1 is provided with a support seat 3, and the top of the support base 3 is provided with an adjustment platform 4, and the adjustment platform 4 and the support base 3 They are connected by clamping strips 5, on which clamping nails 15 are fixedly connected, the clamping strips 5, the support base 3 and the outer cover 7 are helpful for the support, fixation and protection of the adjustment table 4.

[0012] The adjustment table 4 is provided with a telescopic sleeve 41, and an adjustment plate 411 is installed on the expansion sleeve 41. The top surface of the adjustment plate 411 is connected with the compression bolt 6, and the compression bolt 6 is connected with the adjustment plate 4. The outer cover 7 is threaded, and the compression bolt 6, the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com