Integral type curtain wall structure

A monolithic and curtain wall technology, applied in the direction of walls, building components, building structures, etc., can solve the problems of indoor artificial lighting intensity reduction, etc., and achieve the effect of expanding the area and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

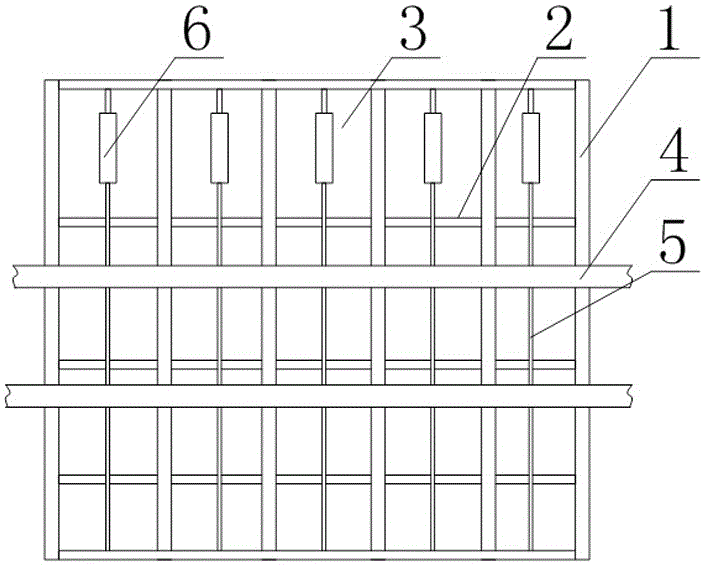

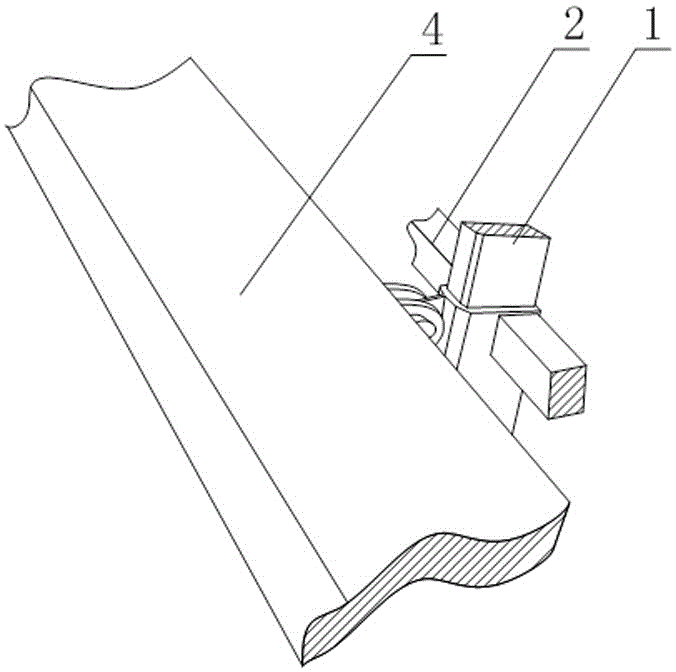

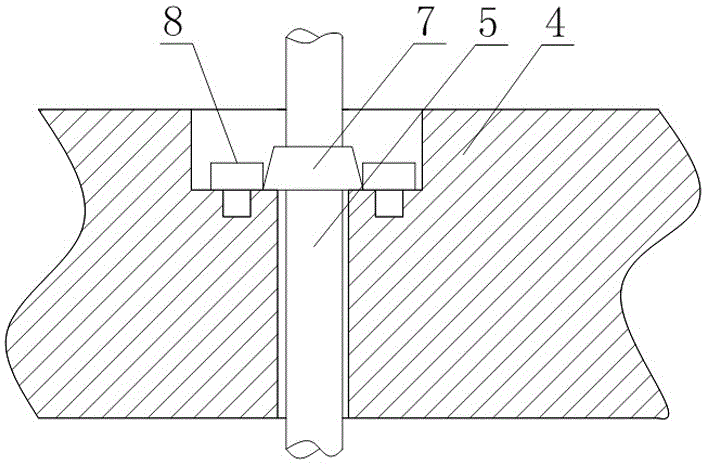

[0040] Such as Figure 1 to Figure 4 As shown, the integral curtain wall structure includes a glass installation frame fixed on the building wall, and there are a plurality of frame-shaped areas on the glass installation frame, and curtain wall glass 3 is installed in the frame-shaped areas, and at least A horizontal beam 4 and at least one vertically arranged stay cable 5, the upper and lower ends of the stay cable 5 are fixed, and the stay cable 5 is in a tensioned state;

[0041] Both ends of the crossbeam 4 are fixed on the building wall, and the crossbeam 4 is located between the two ends of the stay cable 5, the stay cable 5 passes through the crossbeam 4, and the stay cable 5 is fixedly connected with the crossbeam 4, and the glass mounting frame Connected to beam 4.

[0042] In the prior art, in order to realize the sound insulation and heat insulation inside and outside the building, the curtain wall glass 3 is generally arranged as double-layer glass, like this, the...

Embodiment 2

[0047] The present embodiment is further limited on the basis of embodiment 1, as Figure 1 to Figure 4 As shown, as a specific implementation form of the glass mounting frame, the glass mounting frame includes a plurality of vertical bars 1 and a plurality of horizontal bars 2, the vertical bars 1 are parallel to each other, and the horizontal bars 2 are parallel to each other. The frame-shaped area is a rectangular local area surrounded by the cross bar 2 and the vertical bar 1 , and the connection point between the cross bar 4 and the glass installation frame is located at the intersection of the cross bar 2 and the vertical bar 1 . In the above structure, the interaction force generated between the beam 4 and the glass mounting frame can be transmitted to the surrounding through the horizontal bar 2 and the vertical rod 1 at the connection point, which can effectively avoid the damage of the glass mounting frame caused by excessive local stress of the glass mounting frame ...

Embodiment 3

[0062] This embodiment further defines the present invention on the basis of any one of the technical solutions provided in embodiment 1 or embodiment 2:

[0063] Such as Figure 1 to Figure 4 As shown, in order to make the length of the cable 5 suitable for the glass installation frame as short as possible, which is beneficial to the constraint effect of the cable 5 on the horizontal deformation of the beam 4, the upper and lower ends of the cable 5 are respectively fixed on the wall of the building for Install the glass mounting frame on the upper frame and lower frame of the frame.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com