Prefabricated splicing-combined transformer substation

A prefabricated assembly and combined technology, applied in the field of substations, can solve the problems of long construction period, difficulty in matching types of work, poor construction quality, etc., and achieve the effect of shortening the construction period, improving the efficiency of matching types of work, and reducing the amount of on-site operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

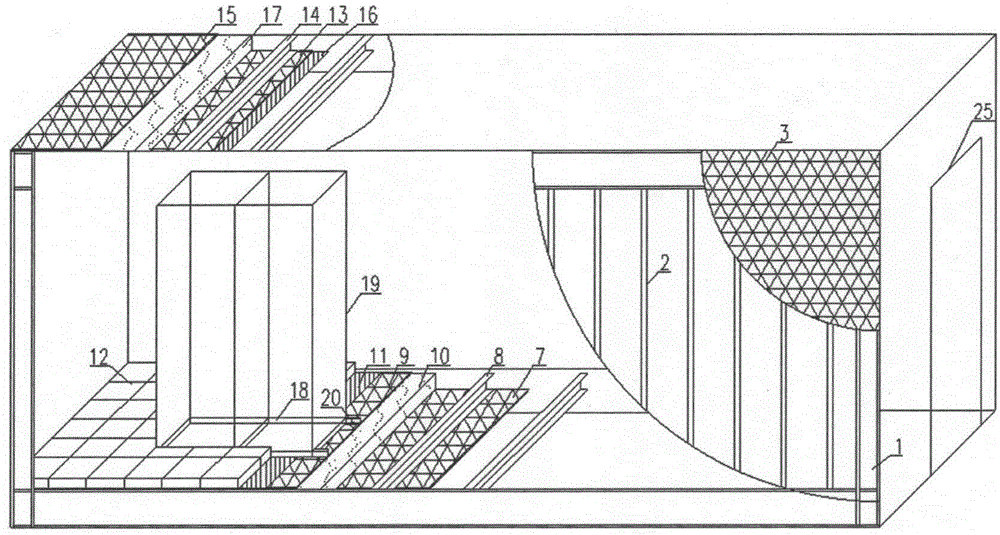

[0019] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

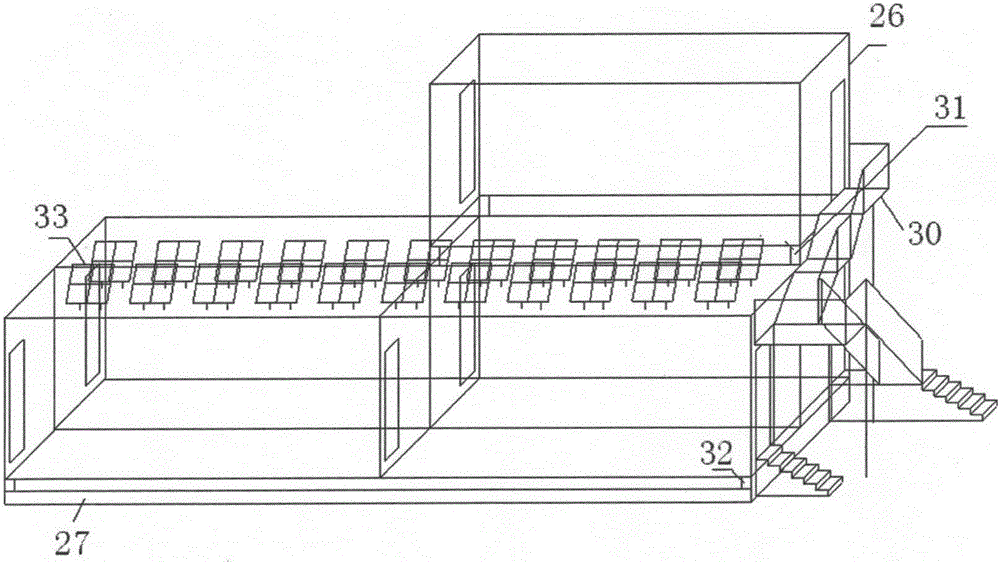

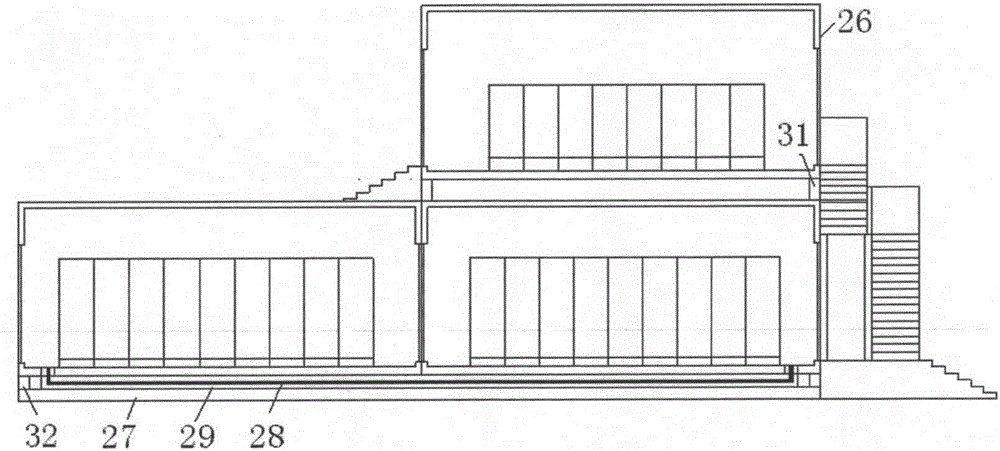

[0020] combine figure 1 and figure 2 , the installation process of a prefabricated assembled combined substation provided by the present invention is as follows:

[0021] 1) The factory processes the prefabricated unit 25 and the prefabricated outdoor staircase 30 .

[0022] 2) Excavate the earthwork at the installation site, and pour reinforced concrete to form the foundation 27 .

[0023] 3) The foundation 27 is embedded with a cable 1 28, and the cable 1 28 is passed through the installation cable sleeve 29. The first cable 28 is in electrical communication with the second cable 24 drawn from each prefabricated unit 25 .

[0024] 4) Transport the prefabricated unit 25 and the prefabricated outdoor staircase 30 to the installation site. The prefabricated unit 25 is connected to the foundation 27 with the unit anchor node 32...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com