Cable presetting device for horizontal well

A technology for horizontal wells and cables, applied in wellbore/well components, earthwork drilling and production, etc., can solve the problems of cable lowering failure, cable damage, fracture, etc., achieve high fishing success rate and improve the safety of going down well

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

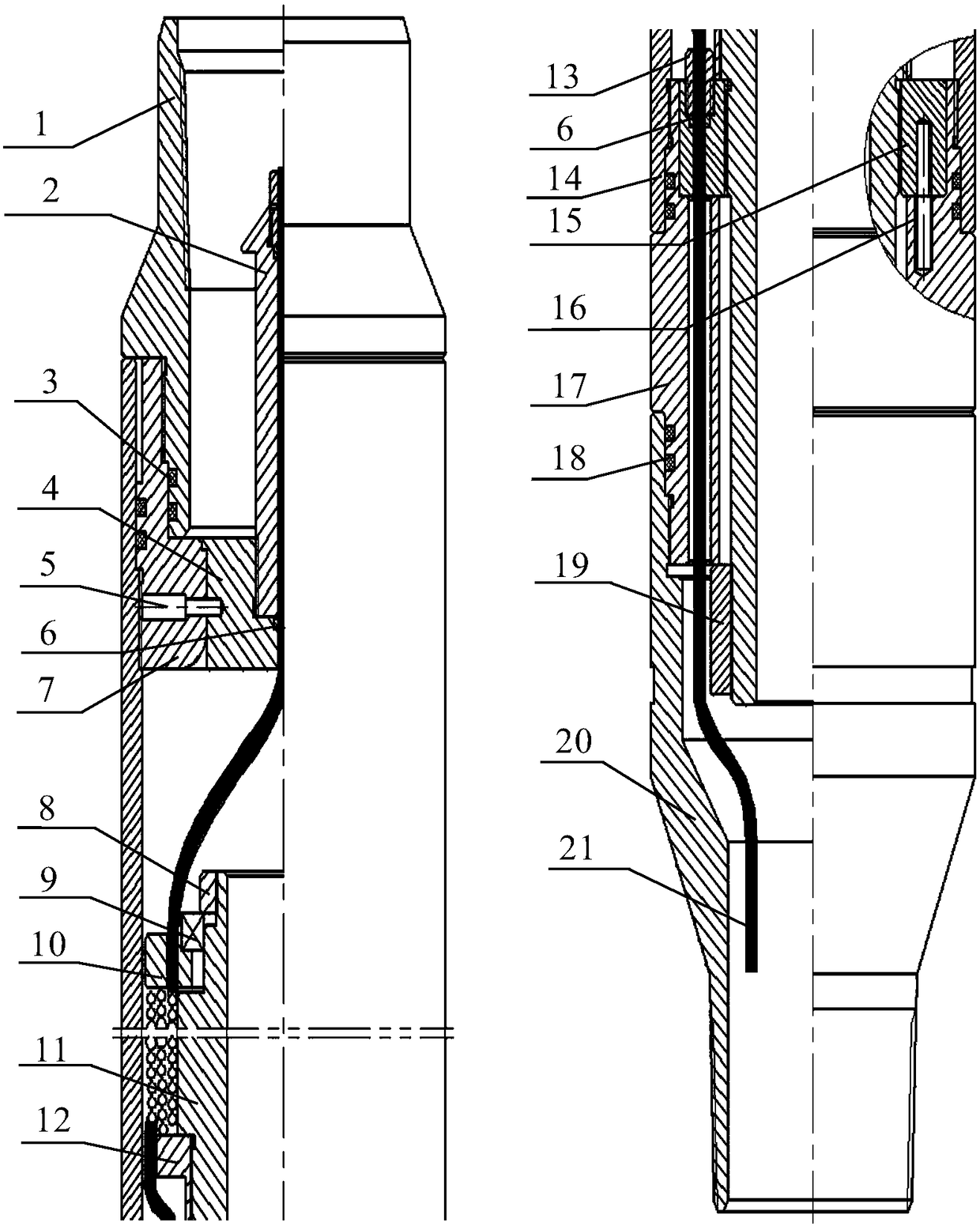

[0011] Specific implementation method: see figure 1 : The present invention consists of an upper joint 1, a fishing head 2, a sealing ring 3, a fishing head seat 4, a shear pin 5, a copper ring 6, a shear pin seat 7, a bearing fastening ring 8, a bearing 9, a baffle plate 10, and a central tube 11 , cable lead-out device 12, fastening pin 13, jacket 14, anti-rotation seat 15, anti-rotation pin 16, connecting sleeve 17, sealing ring 18, fastening nut 19, lower joint 20, cable 21; Connect the shearing pin seat 7, jacket 14, connecting sleeve 17, lower joint 20, and cable 21 in turn from top to bottom; the fishing head 2 fixes the cable 21 on the fishing head seat 4 through the thread and the copper ring 6, and the fishing head seat 4 is cut off The pin 5 is fixed on the shearing pin seat 7; the bearing fastening ring 8 connects the bearing 9, the baffle 10, the central tube 11, and the cable lead-out device 12 sequentially from top to bottom; the bearing fastening ring 8 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com