An anti-leakage device and processing method for filling port of automobile expansion kettle

A technology of expansion kettle and filling port, which is used in engine cooling, machine/engine, mechanical equipment, etc., can solve problems such as leakage and affect air tightness, so as to increase heat dissipation efficiency, improve air tightness, and reduce gap changes amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

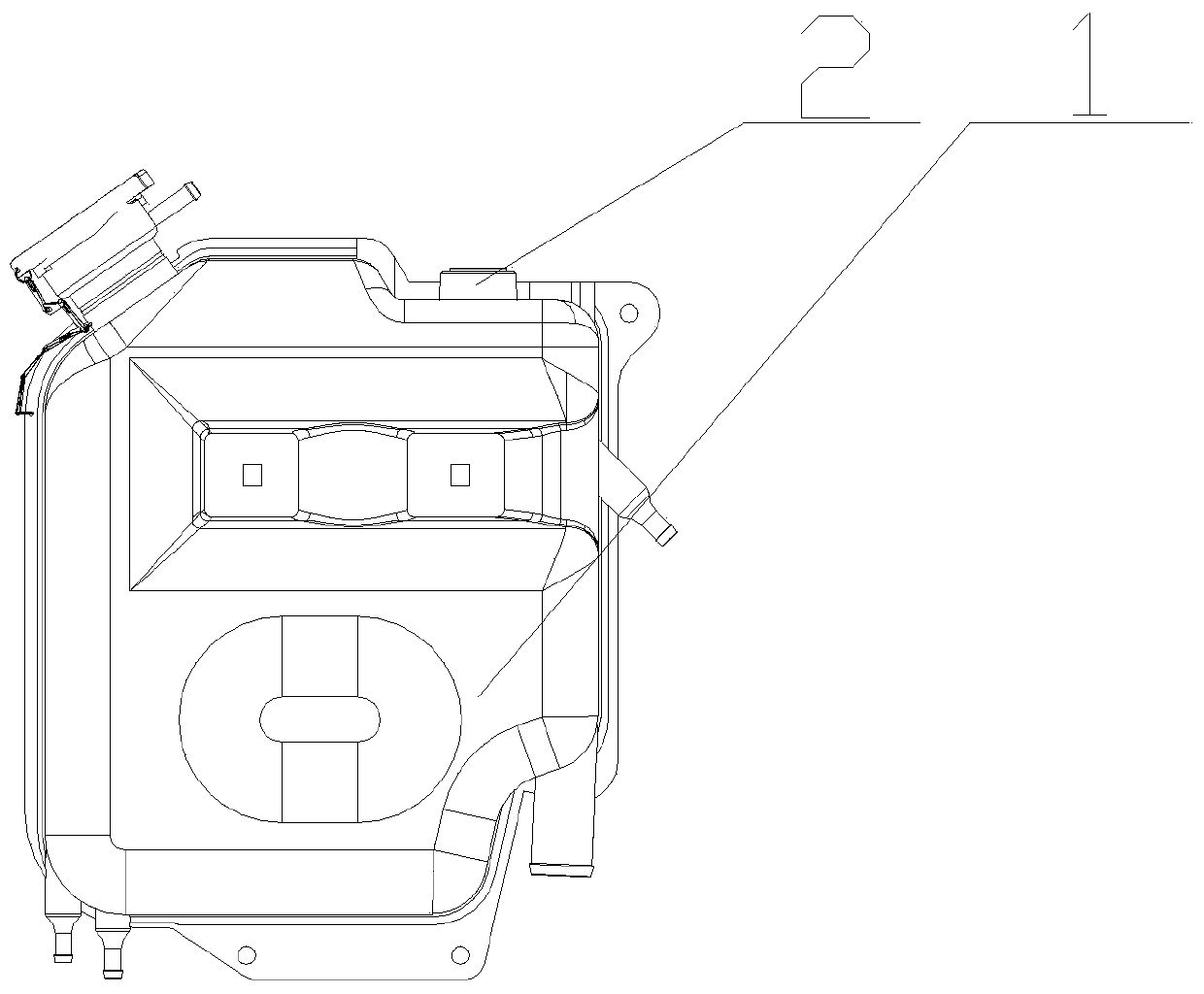

[0021] Please refer to figure 1 , 2 , an anti-leakage device for the filling port of an automobile expansion pot, comprising an expansion pot 1, the expansion pot 1 is provided with a filling port 2, and also includes an anti-leakage device, and the anti-leakage device is arranged in the filling port 2 .

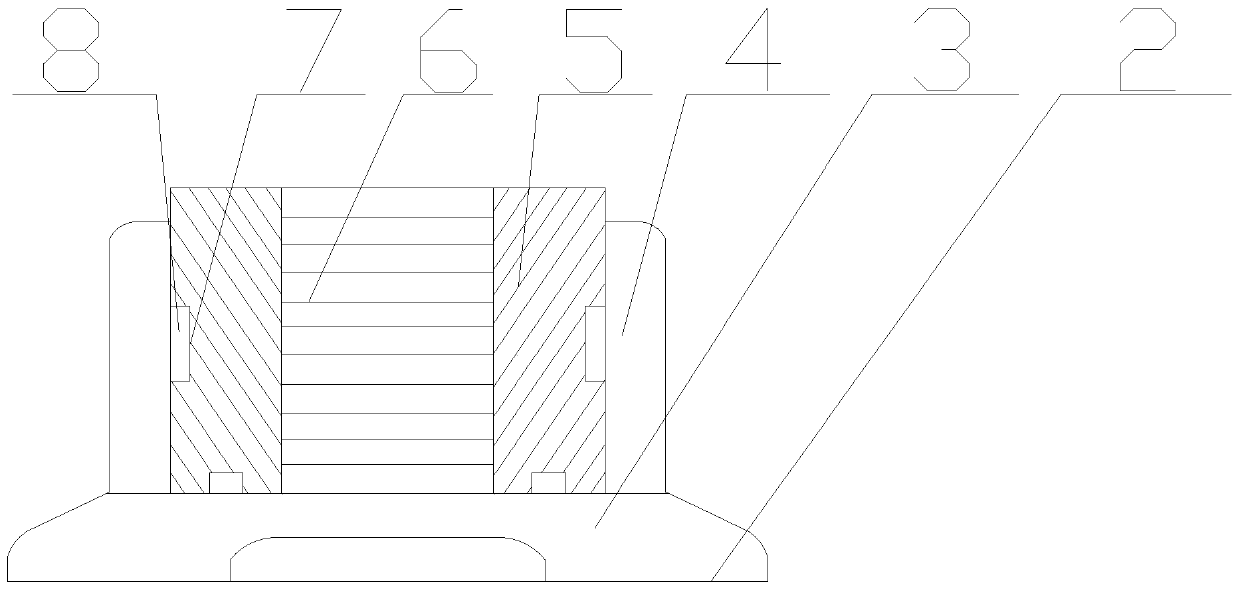

[0022] In this embodiment, the filling port 2 includes a connecting block 3, an outer ring sleeve 4 and 5 pieces of copper nut inserts, the connecting block 4 is fixed on the expansion kettle 1, and the outer ring sleeve 4 and copper The nut inserts 5 are all arranged on the connecting block 3, the outer ring sleeve 4 is set on the outer wall of the copper nut insert 5, the shape of the copper nut insert 5 is a concentric cylinder, and the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com