Dry-type mechanical sealing device of ultra-high-speed homogenizer

A technology of mechanical sealing device and homogenizer, applied in the direction of engine sealing, mechanical equipment, engine components, etc., can solve problems such as difficult application and easy fire, and achieve the effect of improving reliability, precision and adaptability of products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

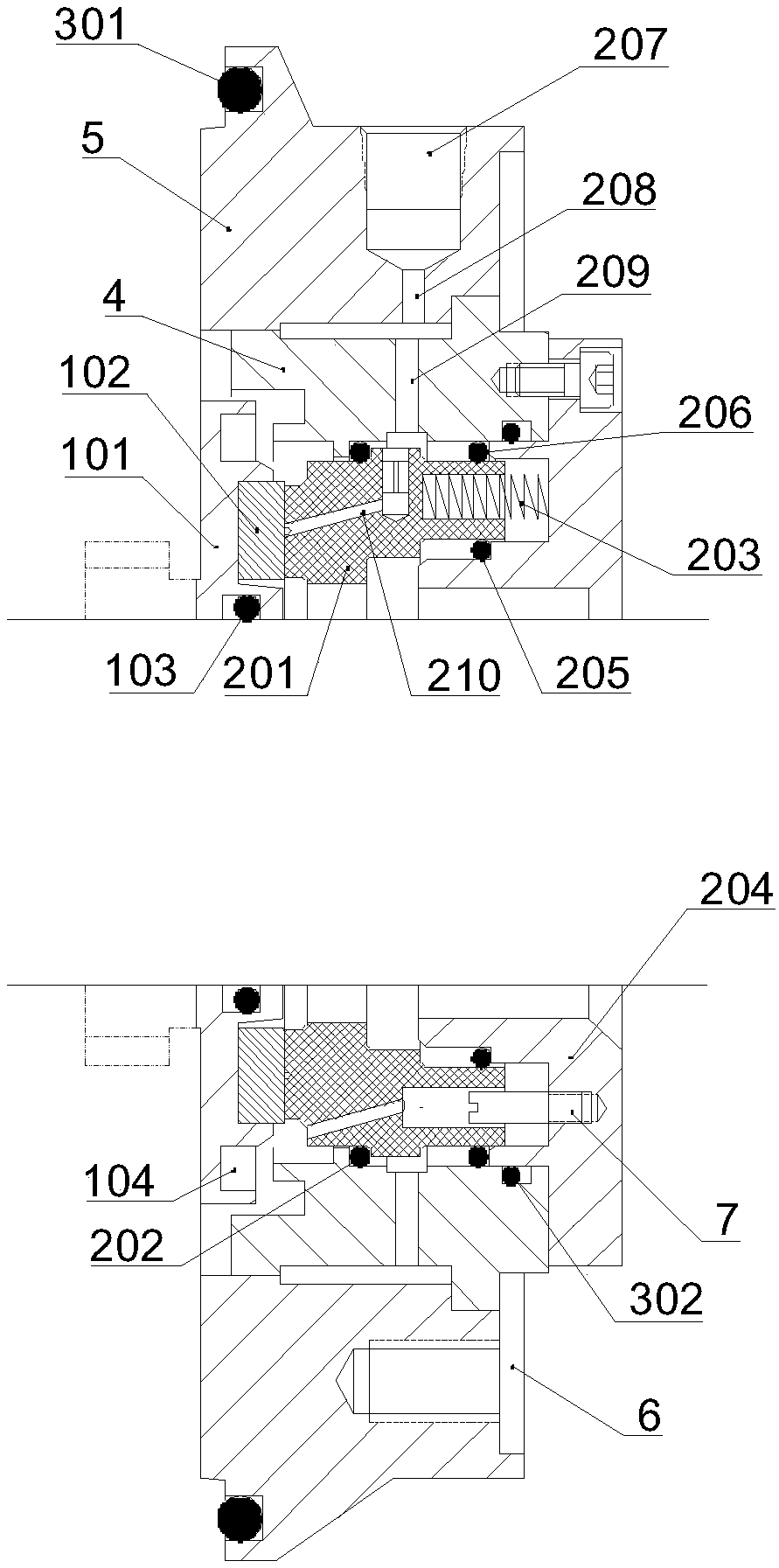

[0027] This embodiment provides a dry mechanical seal device for an ultra-high speed homogenizer, such as figure 1 As shown, it includes a moving ring 102 assembly, an elastic compensation assembly, and an auxiliary sealing assembly.

[0028] The moving ring 102 assembly includes a moving ring seat 101, a moving ring 102 and a moving ring O-ring 103. The moving ring seat 101 is sheathed on the rotating shaft, and the moving ring 102 is embedded in the moving ring seat 101 to form a main sealed rotating part. The outer side of the moving ring seat 101 is provided with an annular groove 104, which facilitates the balance of the sealing surface and reduces the weight of the mechanical sealing device. The moving ring 102 is made of a material with good thermal conductivity, high hardness and good thermal stability, and the surface is ground and polished.

[0029] The elastic compensation assembly includes a stationary ring 201, a spring 203, a spring seat 204 and an air cushion a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com