Plunger pump driving device with automatic compensation function

A driving device and automatic compensation technology, which is applied to the components of pumping devices for elastic fluids, pumps with flexible working elements, pumps, etc., can solve the problems of difficult assembly and adjustment of negative pressure parameters, complex structure, etc. Reduce the difficulty of processing and assembly adjustment, achieve intermittent lubrication, and simplify the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

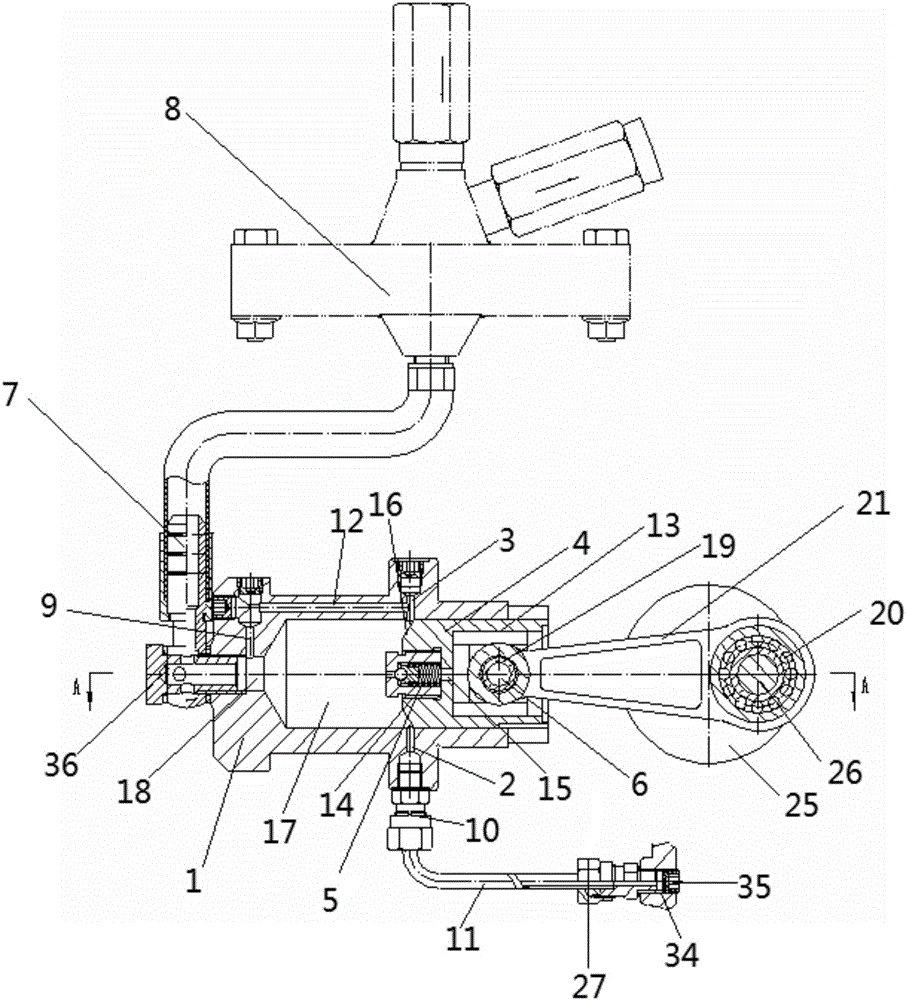

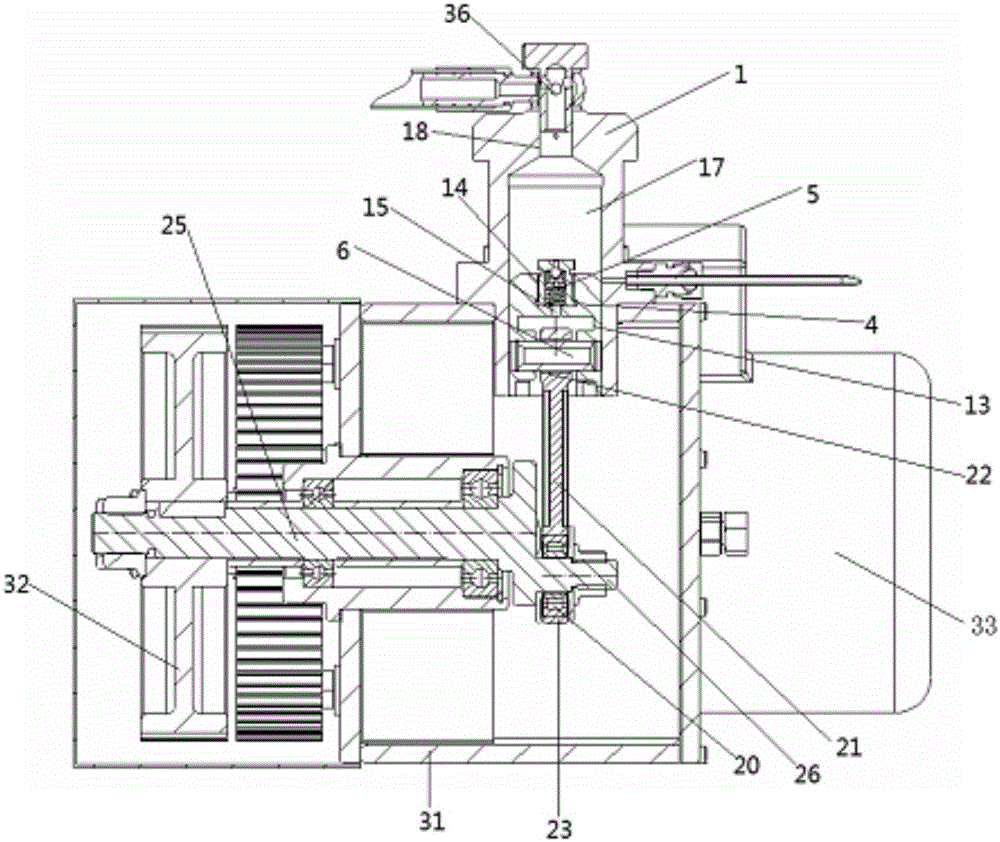

[0031] The present invention is an automatic compensating plunger pump driving device, the structure is as follows: figure 1 , 2 As shown, it includes a hollow cylinder body 1, a plunger 4 is arranged inside the cylinder body 1, a constant pressure relief valve 5 is arranged inside the plunger 4, a plunger pin 6 is arranged on the plunger 4, and a plunger pin 6 is arranged on the plunger pin 6 Connect the crank drive mechanism, the cylinder 1 is connected with the hydraulic cavity of the quantitative diaphragm pump head 8 (the quantitative diaphragm pump head 8 can be any existing hydraulic quantitative diaphragm pump head) through the right angle-articulated rubber hose assembly 7, The cylinder body 1 is connected to the oil storage tank through a hose 11 .

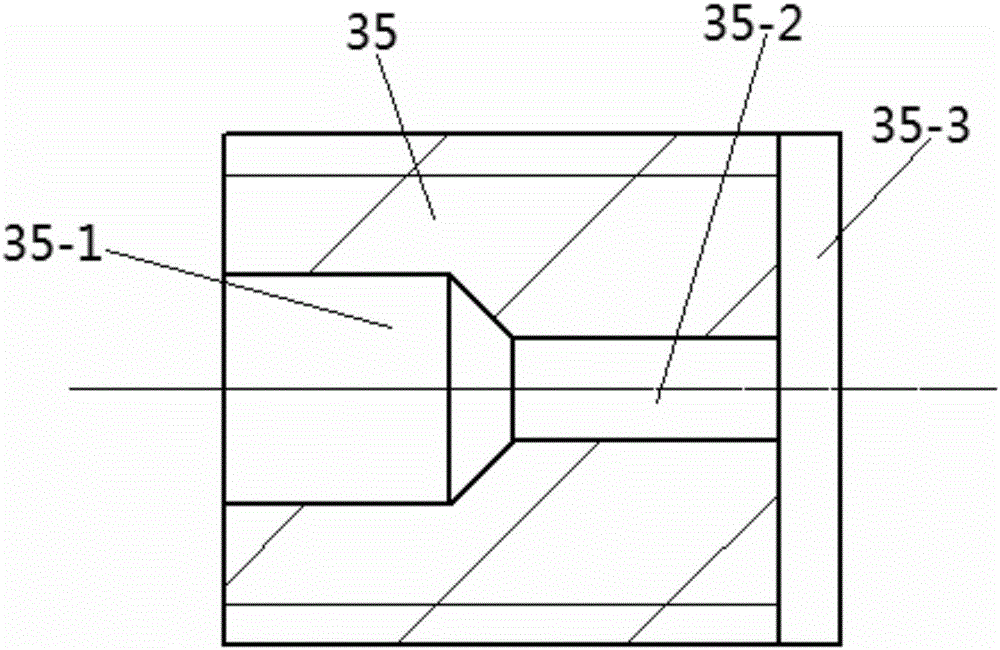

[0032] The side wall of the cylinder body 1 is respectively provided with a stepp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com