Harvester gearbox output shaft mechanism and harvester gearbox

A technology for gearboxes and harvesters, applied in the field of gearboxes, can solve the problems of reducing product performance, cumbersome processes, affecting the structural accuracy and service life of gearboxes, etc., to improve service life and stability, simple and compact structure, and easy maintenance. effect used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

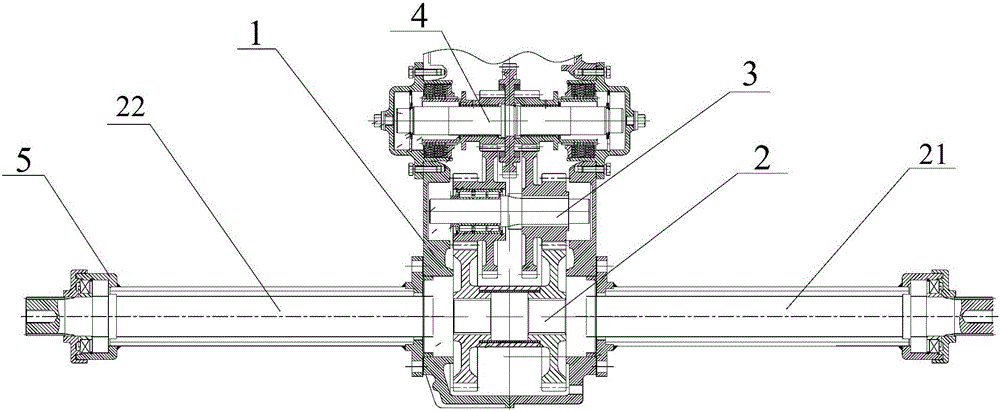

[0019] Such as picture 1 , picture 2 As shown, a harvester gearbox includes a gearbox housing 1 and an output shaft mechanism 2, an idler shaft part 3, and a steering clutch shaft part 4 arranged in the housing 1;

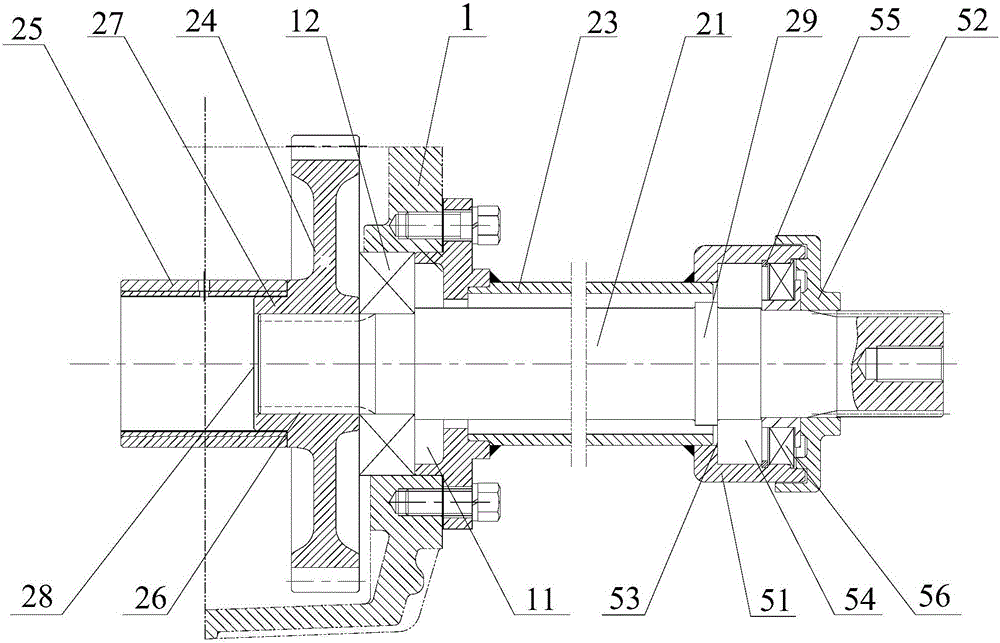

[0020] The output shaft mechanism 2 includes a left half shaft 21, a right half shaft 22 and a corresponding half shaft sleeve 23, and the left 21 and right half shaft 22 are rotatably and fixedly sleeved in the half shaft sleeve 23. The output shaft mechanism 2 also includes a transmission output gear 24 and a process retaining ring 25. The center of the transmission output gear 24 is provided with a mounting hole 26 with an internal spline. The left 21, right half shaft The outer edge of the bottom of 22 is provided with corresponding external splines. The bottoms of the left 21 and right half shafts 22 pass through the mounting holes 26 and are spline-coupled with the transmission output gear 24. The outer edges of the transmission output gear 24 are inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com