Fixed loading shell decomposer

A decomposing machine and artillery shell technology, applied in the directions of ammunition, weapon accessories, offensive equipment, etc., can solve the problems of low processing efficiency of artillery shell decomposing technology, and achieve the effect of simple structure and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Preferred embodiments of the present invention are described below, and those skilled in the art will be able to implement them using related technologies in the field as described below, and can better understand the innovations and benefits of the present invention.

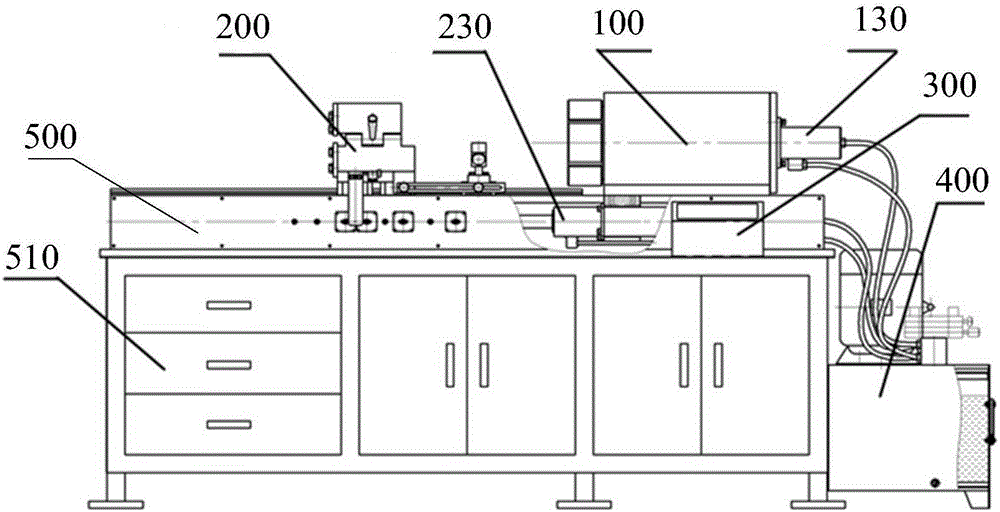

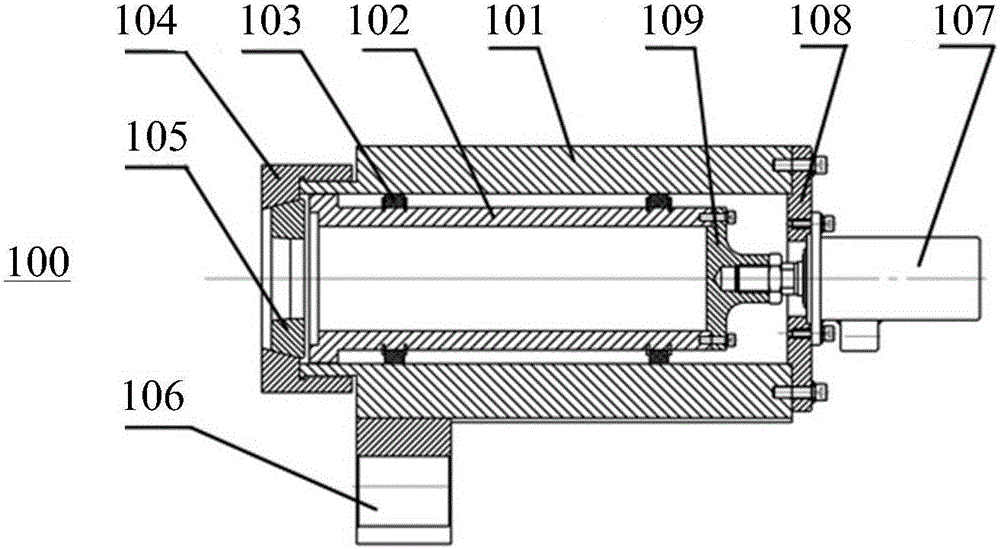

[0016] Such as Figure 1-2 Shown is a fixed-mounted shell disintegrator described in this embodiment, a fixed-mounted shell disassembler, comprising: a bracket 500, a fixed nose 100 and a sliding tail 200; the fixed nose 100 is set On the bracket 500, the fixed machine head 100 includes a shaft sleeve 102 arranged in the machine head housing 101, and a pulley sleeve 103 is arranged between the shaft sleeve 102 and the machine head housing 101 so that the shaft sleeve 102 can Move axially in the machine head housing 101, the front end of the shaft sleeve 102 is provided with a clamping elastic mold 105, and the clamping elastic mold 105 is sleeved on the said machine head housing 101 through a fixed sleev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com