Method and crank-connecting rod mechanism for full constant-volume combustion of IC engine

A crank-link mechanism and equal-volume combustion technology, which is applied in the direction of machines/engines, mechanical equipment, etc., can solve the problems of internal combustion engine time loss, exhaust energy increase, and small effective arm strength, so as to reduce exhaust energy loss, vibration and noise reduction , The effect of improving the thermal efficiency of the cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

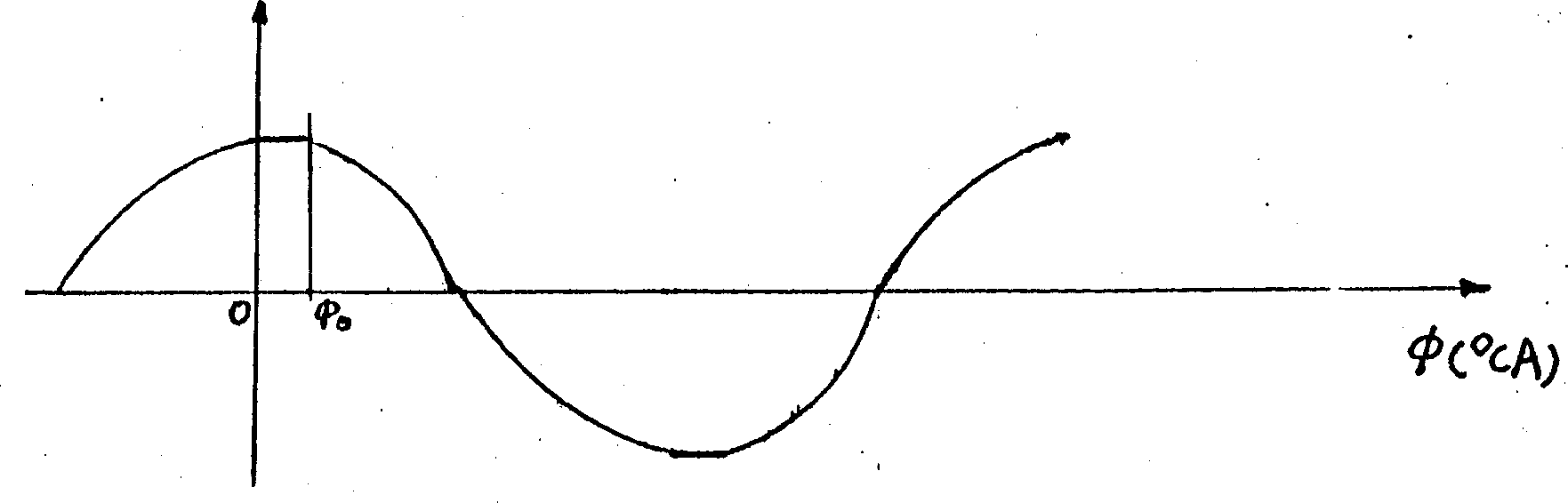

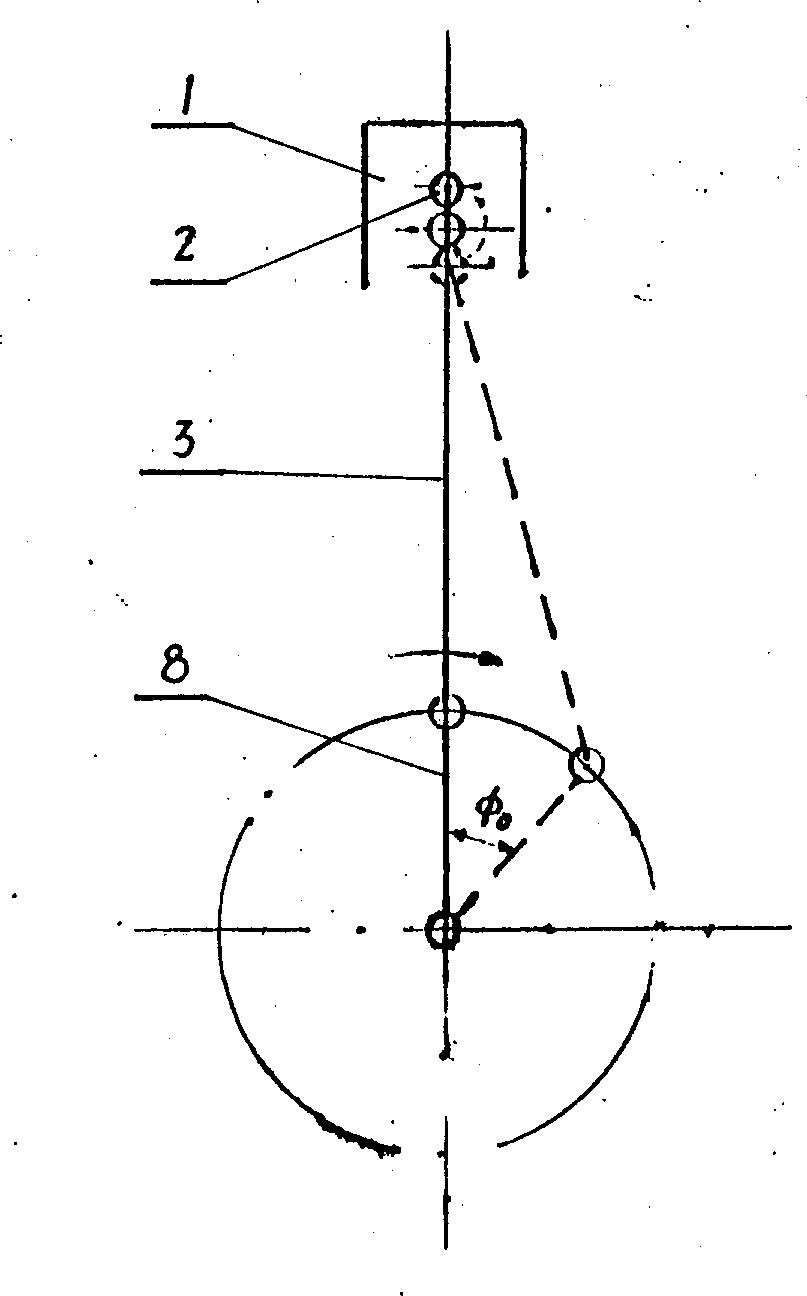

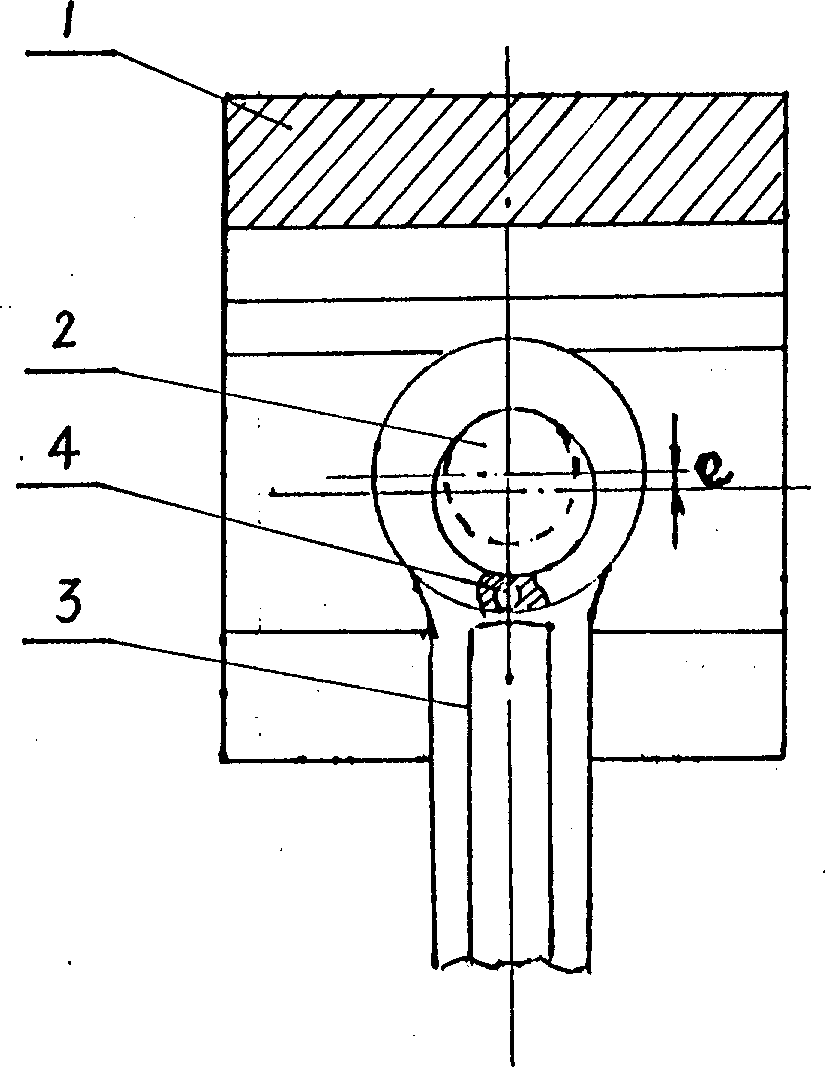

[0025] The invention is a new breakthrough for the combustion of the current internal combustion engine. The internal combustion engine has been born for more than 100 years. After people's unremitting efforts, a more reasonable combustion process, a more optimized structure, and electronic control technology have greatly improved the performance of the internal combustion engine. The thermal efficiency of modern diesel engines has reached more than 40%, and gasoline engines have reached More than 30%. Nevertheless, the work done by people on the internal combustion engine is always carried out on the basis of the traditional working cycle of the internal combustion engine, and the further improvement of the thermal efficiency of the internal combustion engine has been limited by the traditional working cycle. Based on the above-mentioned situation, the applicant analyzes the traditional working cycle of the internal combustion engine and thinks that only by prolonging the res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com