Runner cycloid speed changing stress application mechanism

A technology of booster mechanism and runner, which is applied in the field of crankshaft transmission machinery and variable speed transmission machinery, and can solve the problems of high power consumption under gas pressure, low vibration and energy efficiency, and insufficient combustion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

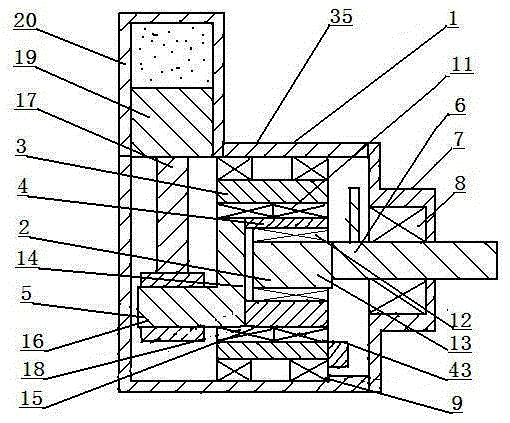

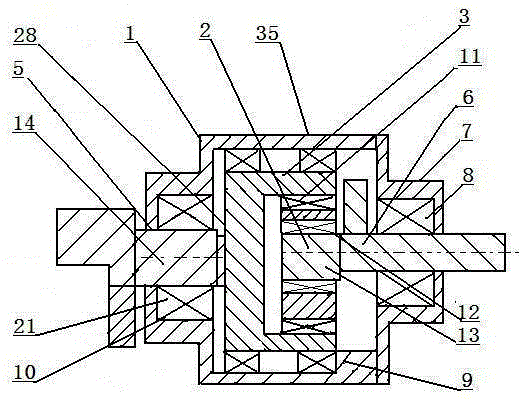

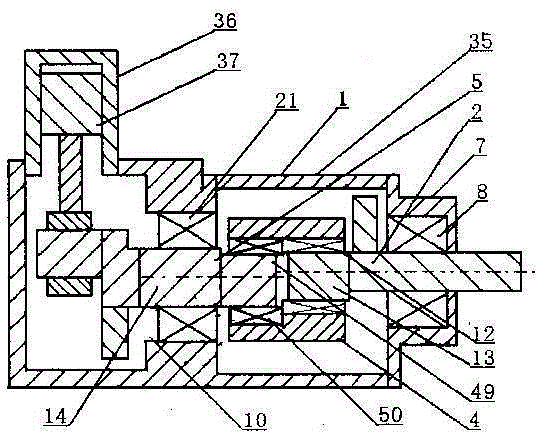

[0028] Such as figure 1 , Figure 5 , Figure 6 As shown, a runner cycloidal speed change boosting mechanism 35 is made up of body 1, crankshaft 2, runner 3, cycloid wheel 4 and crankshaft 5; crankshaft 2 is an input shaft, crankshaft 5 is an output shaft, and the runner 3 and cycloid wheel 4 are cycloid control devices. The shaft body 6 of the crankshaft 2 is supported and installed in the bearing seat 8 of the frame 7 of the body 1, the bearing support of the runner 3 is installed in the bearing seat 9 inside the body 1, and the runner 3 is installed eccentrically relative to the shaft body 6 of the crankshaft 2 , Balance weight 43 is installed on the running wheel 3. There is an eccentric bearing raceway 11 on the runner 3, the shaft body 15 of the cycloidal wheel 4, and the bearing support is installed in the eccentric bearing raceway 11 of the runner 3, and the inside of the cycloidal wheel 4 is provided with an eccentric bearing raceway 12, The journal 13 of the cranks...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com