Fire retardant powder filling machine

A filling machine and flame retardant technology, applied in the field of flame retardant powder filling machine, can solve the problems of inability to meet large-scale industrial production, low production efficiency of production line, difficulty in improving processing efficiency, etc. Effects of industrialized production, improving production efficiency and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

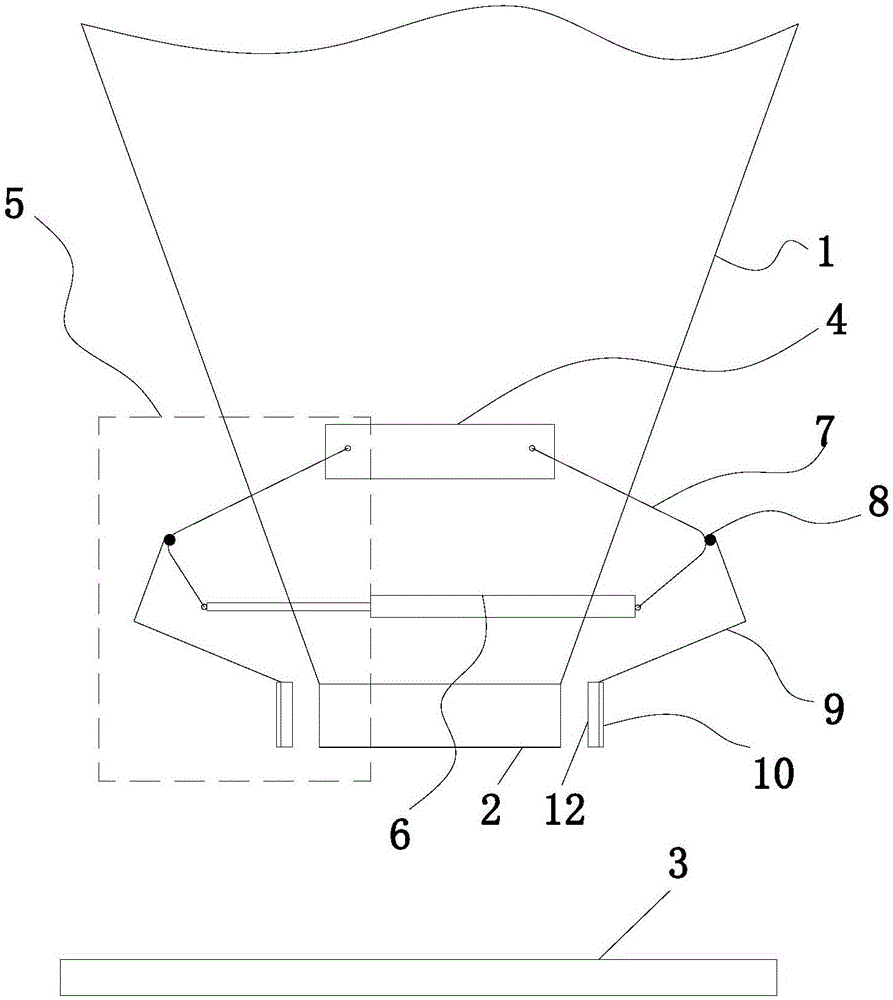

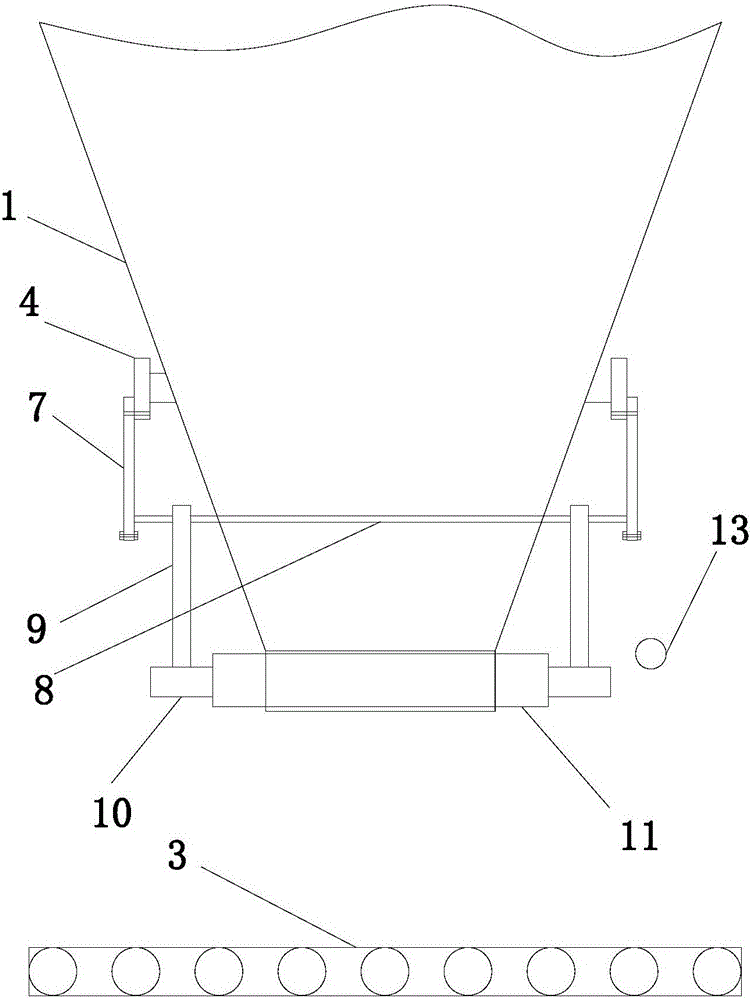

[0012] Example. A flame retardant powder filling machine, composed of figure 1 and 2 As shown, it includes a conical tank body 1, the lower end of the conical tank body 2 is provided with a circular feeding port 2, and a conveying roller 3 is arranged below the circular feeding port 2, and a clip is provided on the conical tank body 1. Bag device; the bag clamping device includes two symmetrically arranged clamping jaw mechanisms 5 fixed on the conical tank body 1 through the connecting piece 4, and an air cylinder 6 is arranged between the two clamping jaw mechanisms 5; the clamping jaw mechanism 5 includes a Two curved connecting rods 7 on both sides of the shaped tank body 1, one end of each curved connecting rod 7 is hinged on the connector 4, the other end is hinged on the end of the cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com