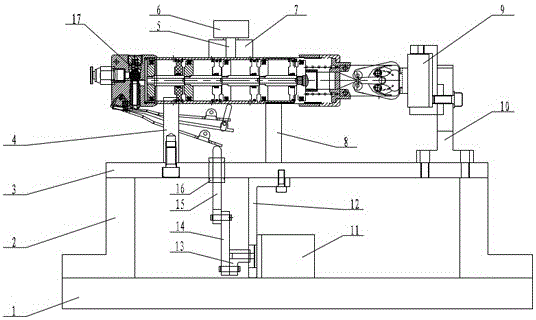

Test bench for service life of clamp tool

A technology of life testing and clamp clamps, which is applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc., can solve the problems of lack of life performance testing of single-ear pneumatic clamp clamps, etc., and reduce the cumbersome disassembly process , to ensure the qualified rate and improve the detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

[0016] As shown in the figure, the clamp clamp life test bench includes an installation platform 1 on which a set of support feet 2 are fixed, and a working platform 3 is fixed on the support feet 2 . The clamp support block and the sensor support base 10 are fixedly arranged on the working platform 3 . The clamp clamp support block comprises the first clamp clamp support block 4 that cooperates with the clamp clamp 17 front end and the second clamp clamp support block 8 that cooperates with the clamp clamp 17 rear end, the first clamp clamp support block 4 and The second clamp pliers support blocks 8 are all V-shaped support blocks. In order to improve the stability during detection, a pressing mechanism capable of pressing the clamp body of the clamp clamp 17 from top to bottom is fixedly arranged on the installation platform 1 . The pressing mechanism specifically...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com