Novel heat conductivity coefficient test apparatus and heat conductivity coefficient test method

A technology of thermal conductivity and testing device, applied in the field of new thermal conductivity testing device, can solve problems such as complex process, achieve the effect of accurate measurement and eliminate test errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

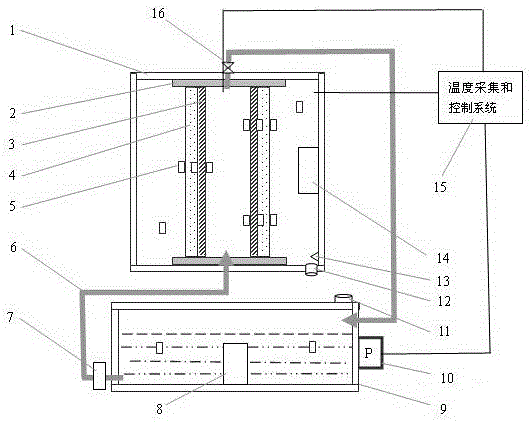

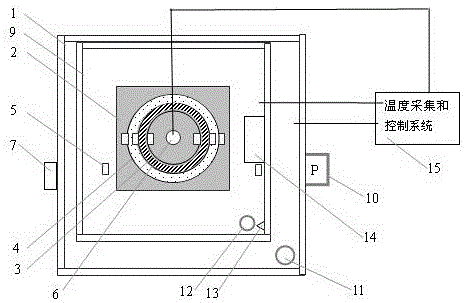

[0026] exist figure 1 Among them, the equipment test box 1 simulates the actual application environment of the thermal insulation pipeline, and measures the thermal conductivity of the test piece. The test piece is placed in the center of the rubber plugging end cover in the equipment test box 1, and the test piece is fixed and blocked by the upper box cover of the equipment test box 1. The temperature of the equipment test box 1 is measured by a plurality of temperature sensors 5, And transmit the data to the acquisition and control system 15, and the acquisition and control system 15 controls the refrigeration equipment 14 to maintain the temperature of the equipment test box 1 to reach balance. The hot water tank 9 simulates the actual temperature inside the heat preservation pipeline, the heating device 8 heats the hot water tank 9, and the temperature is measured by a plurality of temperature sensors 5, and the data is transmitted to the acquisition and control system 15,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com