Liquid drop contact angle solving method under given surface second-level nano-micro structure

A technology of micro-nano structure and contact angle, applied in special data processing applications, complex mathematical operations, instruments, etc., can solve problems such as large influence of human operation factors and complicated measuring devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with accompanying drawing, the present invention will be further described.

[0034] A method for calculating the droplet contact angle under a given surface secondary micro-nano structure according to the present invention comprises the following steps:

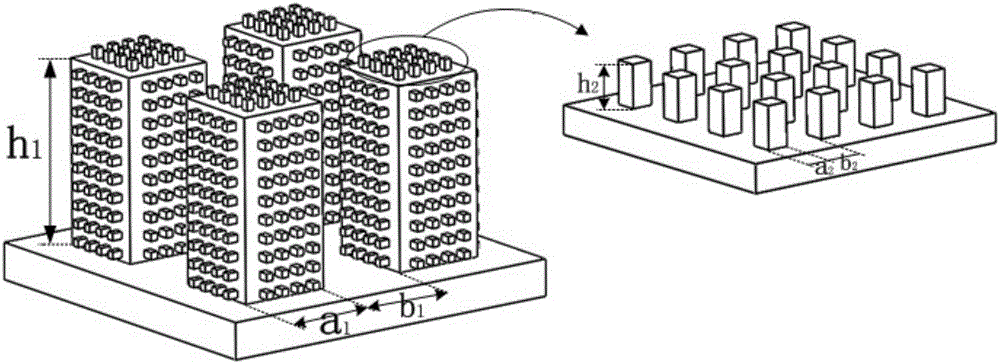

[0035] (1) Measure the structural size of the given secondary micro-nano structure, which can be measured by a micro-nano geometric measuring instrument to measure the relevant size parameters, h 1 ,a 1 ,b 1 ,h 2 ,a 2 ,b 2 . where a 1 (a 2 ),b 1 (b 2 ) and h 1 (h 2 ) are the side length, spacing and height of the microstructure (nanostructure), respectively, and the given secondary micronanostructure such as figure 1 shown.

[0036] Such as figure 1 Shown; It can be seen from the geometric relationship:

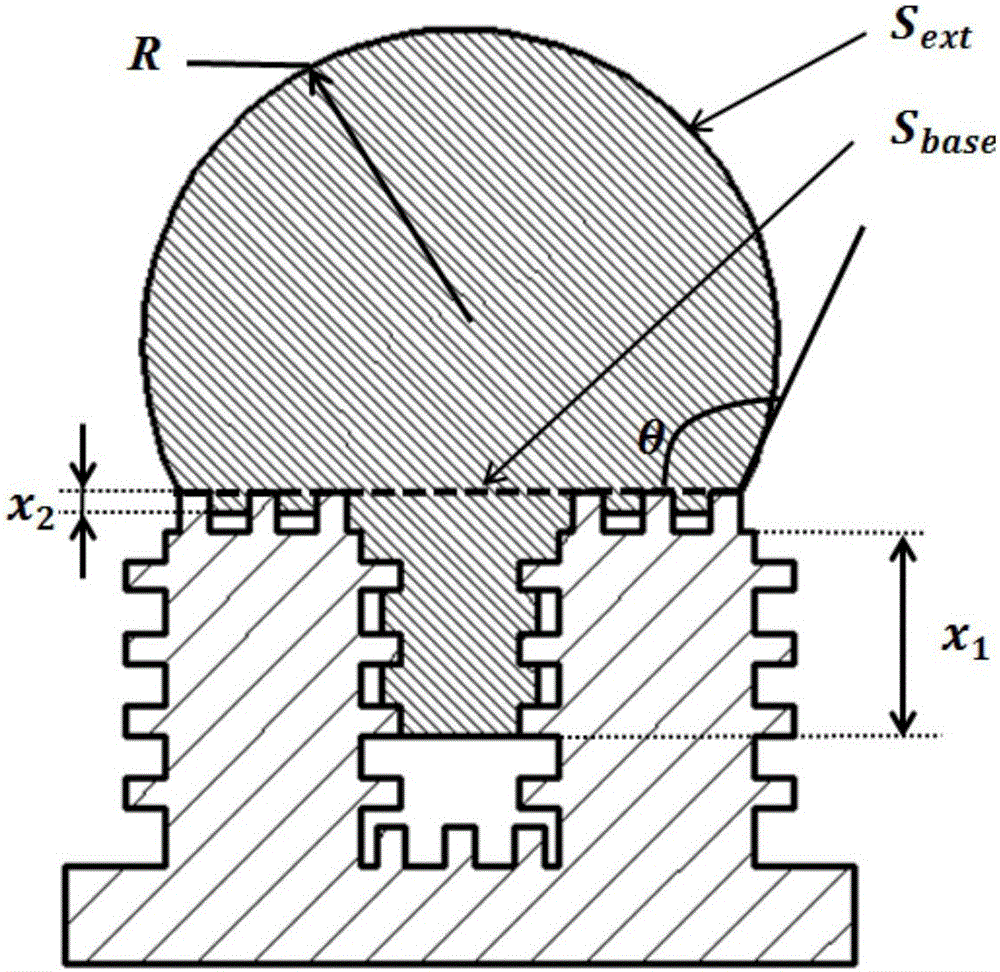

[0037]

[0038] ②S ext = 2πR 2 (1-cosθ)⑵

[0039] ③S base = πR 2 sin 2 θ⑶

[0040]

[0041] Among them, S ext is the outer surface area of the spherical cap droplet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com