co 2 Laser Live Wire Insulation Cutting System and Cutting Method

A live wire and insulation sheath technology, which is applied in the field of CO2 laser live wire insulation sheath cutting system, can solve the problem that the contact area between the puncture contact piece and the cable metal core is difficult to control, mechanical tools can scratch the metal cable core, and it is easy to cause personal injury and death accidents, etc. problems, to achieve the effect of realizing remote all-round monitoring, good skin cutting quality, and meeting the requirements of safety and craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

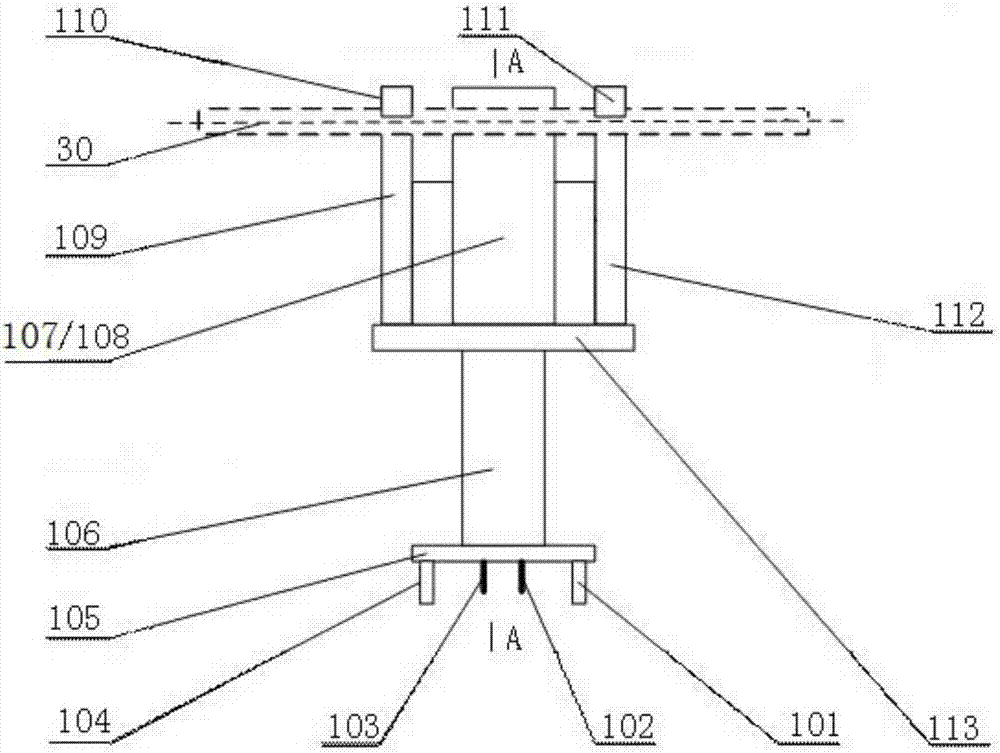

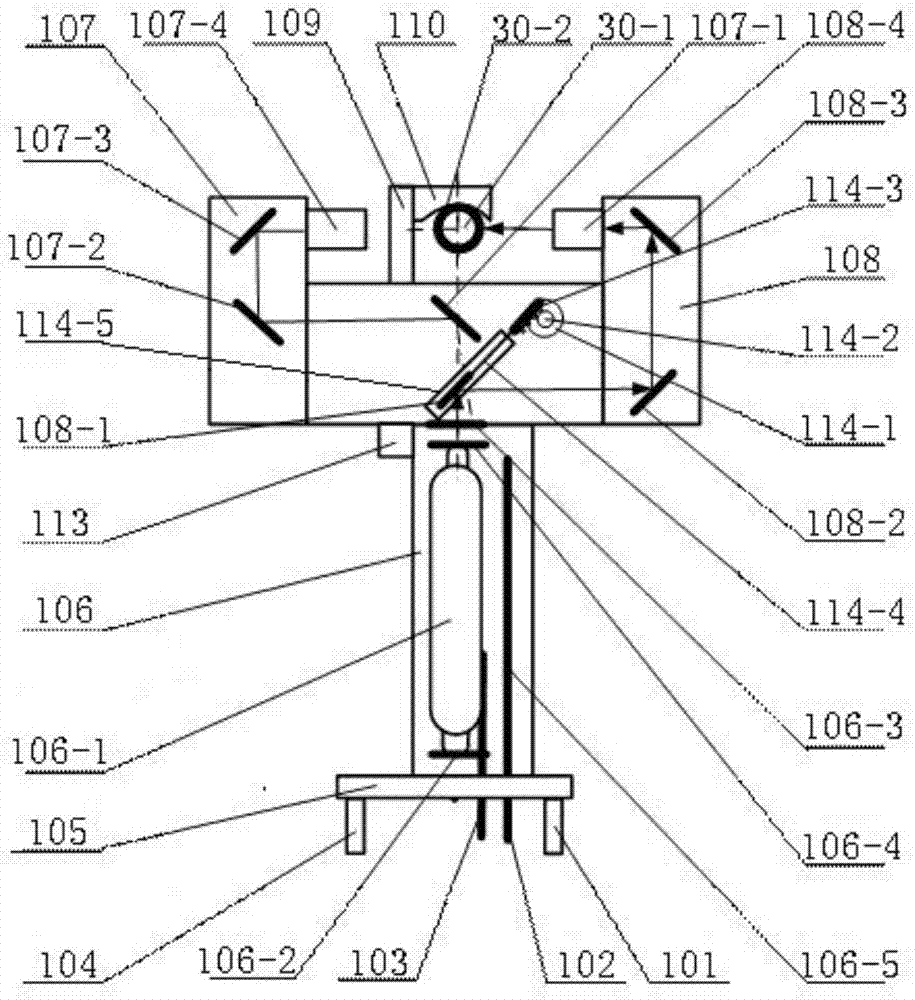

[0041] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0042] Such as Figure 1-Figure 6 As shown, CO 2 Laser live wire insulation sheath cutting system, including CO 2 Laser 106, left optical path system 107, right optical path system 108, control system and suspension mechanism, described left optical path system 107 and right optical path system 108 are arranged on the fixed crossbeam 113, are symmetrically suspended on both sides of live conductor 30 by suspension mechanism, CO 2 The laser 106 is arranged below the fixed crossbeam 113, and its laser beam emission port is facing the charged wire 30; the left optical path system 107 is composed of a left path reflector group and a left path galvanometer box 107-4, and is used for CO 2 The laser beam that the laser 106 sends is guided to the charged wire 30 side; 2 The laser beam that laser 106 sends is guided to the charged wire 30 other sides; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com