Annular cutting machine

A kind of technology of ring cutting machine and head, which is applied to cutting tools, cutting equipment, agricultural machinery and implements, etc., can solve the problems of difficult control of cutting depth, laborious manual operation and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, where the schematic embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

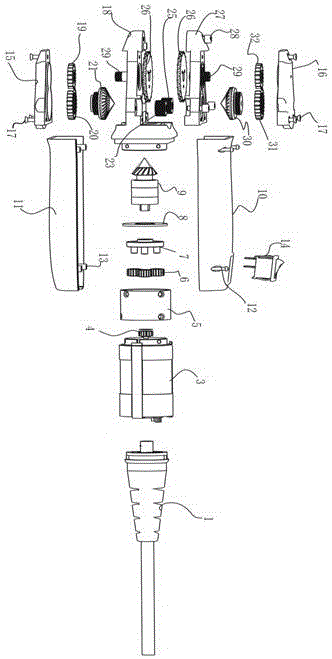

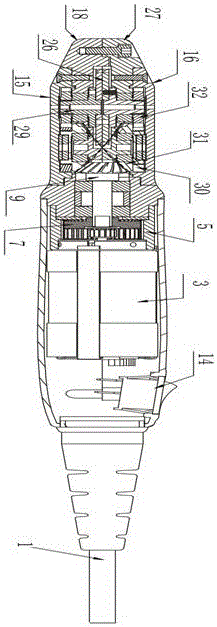

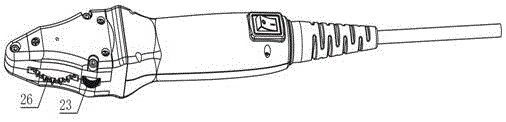

[0022] refer to Figure 1 to Figure 3 , the object of the present invention is to provide a ring cutting machine, comprising

[0023] The plastic shell body composed of the upper plastic shell 10 and the lower plastic shell 11, the front end of the plastic shell body is connected to the machine head body composed of the upper machine head body 27 and the lower machine head body 18, and the rear end of the plastic shell body is connected to the cable line 1;

[0024] The motor 3 is set at one end of the tail of the main body of the rubber shell and connected to the cable 1. The motor 3 is connected to the planetary gear 6 through the sun gear 4 provided on it, and the planetary gear 6 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com