Snap fastener for fabric

A snap-button and fabric technology, applied in the field of snap-button, can solve the problems of human skin discomfort, etc., and achieve the effect of improving production efficiency, simple parts, and not easy to lose

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

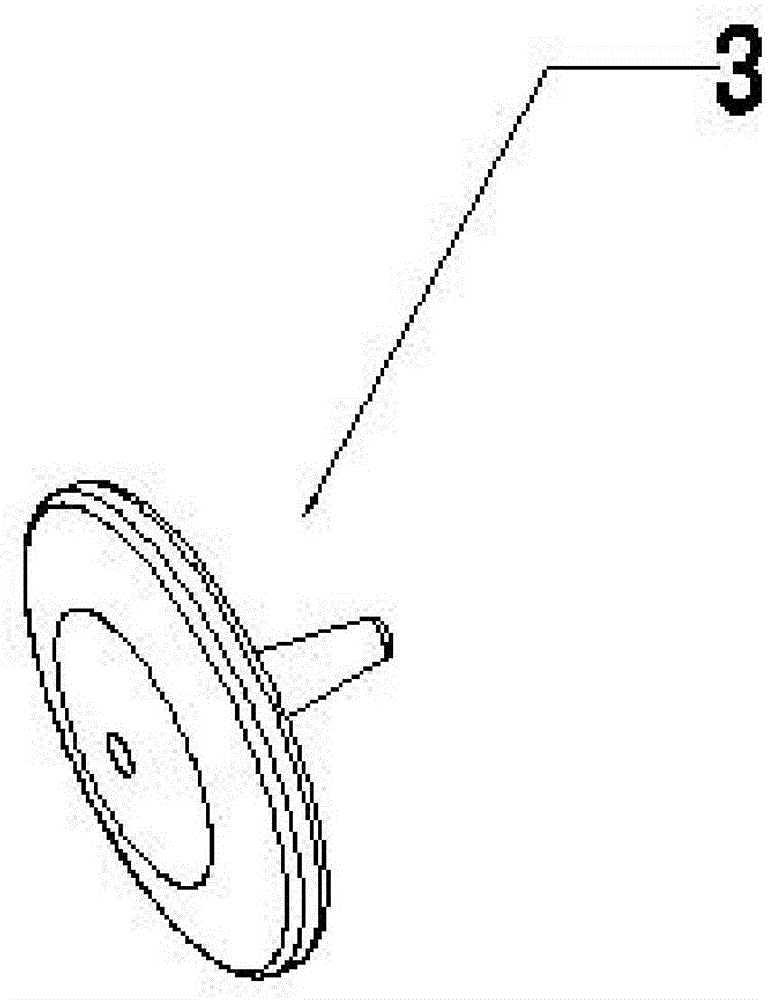

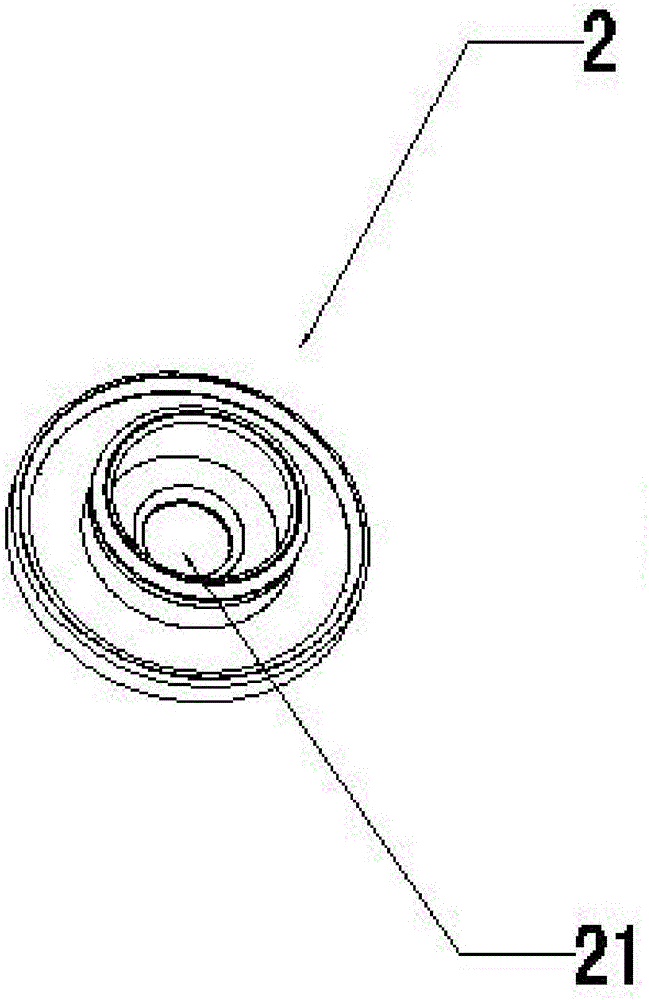

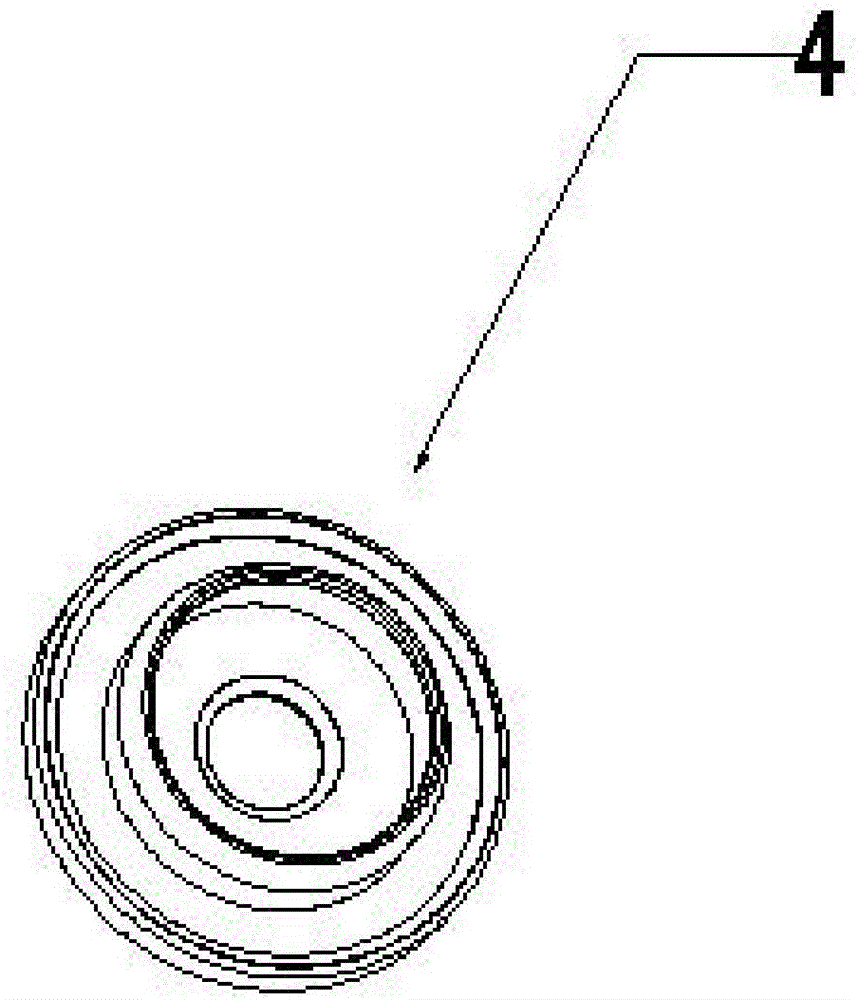

[0044] Such as Figure 5-9 As shown, a snap button for cloth, wherein the cloth 1 includes an outer layer of cloth 11, an inner layer of cloth 12, and a cloth layer gap 13 between the outer layer of cloth 11 and the inner layer of cloth 12. The snap button comprises a male button 2, a female button 4 and a rivet thread 5, wherein the male button 2, the female button 4 are the same as the male button 2 and the female button 4 in the snap button of the prior art (such as Figure 2-3 ) are the same, that is, the male buckle 2 and the female buckle 4 respectively include a fastener body with a middle gap 21 . The male buckle 2 and the female buckle 4 are respectively fixed to the cloth 1 through the rivet line 5, and when in use, the male buckle 2 and the female buckle 4 are fastened to each other.

[0045] Since the structures and methods of fixing the male buckle 2 and the female buckle 4 on the fabric in this embodiment are the same, this embodiment takes the male buckle 2 as ...

Embodiment 2

[0048] Such as Figure 10-13 Shown is an embodiment 2 of a snap button for cloth, wherein the cloth 1 includes an outer layer of cloth 11 , an inner layer of cloth 12 and a cloth layer gap 13 between the outer layer of cloth 11 and the inner layer of cloth 12 . The snap button includes a male button 6, a female button 7 and a rivet thread 5. The male buckle 6 and the female buckle 7 are respectively fixed to the cloth 1 through the rivet line 5, and when in use, the male buckle 6 and the female buckle 7 are fastened to each other. The difference from Embodiment 1 is that the male buckle 6 and the female buckle 7 in Embodiment 2 respectively include a fastener body with a first intermediate space and a second intermediate space (such as Figure 11 Shown); Rivet line 5 is identical with embodiment 1 (as Figure 10 ), having a first end 50 and a second end 53.

[0049] Since the structures and methods of fixing the male buckle 6 and the female buckle 7 on the cloth are the sam...

Embodiment 3

[0051] Such as Figure 14-17 Shown is an embodiment 3 of a snap button for cloth, wherein the cloth 1 includes an outer layer of cloth 11 , an inner layer of cloth 12 and a cloth layer gap 13 between the outer layer of cloth 11 and the inner layer of cloth 12 . The snap button includes a male button 6, a female button 7 and a rivet thread 5. The male buckle 6 and the female buckle 7 are respectively fixed to the cloth 1 through the rivet line 5, and when in use, the male buckle 6 and the female buckle 7 are fastened to each other. The male buckle 6 and the female buckle 7 are the same as those in Embodiment 2, that is, the male buckle 6 and the female buckle 7 respectively comprise a fastener body with a first intermediate space and a second intermediate space (such as Figure 15 shown).

[0052] Such as Figure 14 As shown, the rivet wire 8 has a first end 80 and a second end 82. The first end 80 of the rivet 8 has a rivet head 81. The rivet wire 8 is in a straight state w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com