Non-epoxy sealed mini temperature controller

A temperature controller and epoxy sealing technology, which is applied in the direction of electrical components, electric switches, circuits, etc., can solve the problems of long curing time, strong allergies of epoxy resin, and high material cost, so as to improve market efficiency, save costs, Overcoming allergic strong effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

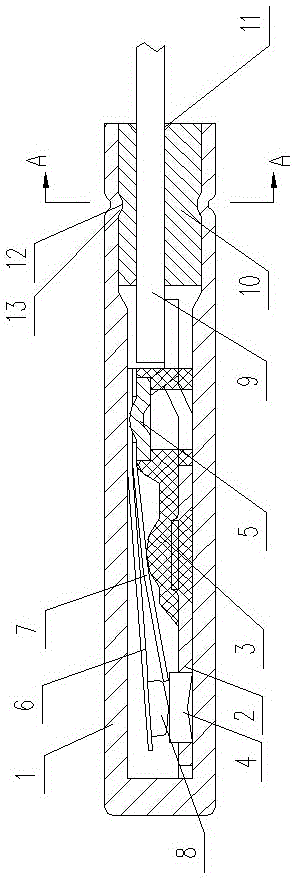

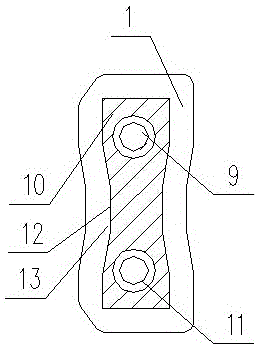

[0011] Such as figure 1 , 2 As shown, it includes a housing 1 with an open end, a metal bottom plate 2 is provided in the housing 1, a base 3 and a static contact 4 are provided on the metal bottom plate 2, and a contact is provided on one end of the base 3 away from the static contact 4 Sheet 5, the housing 1 above the base 3 is provided with a spring sheet 6 and a bimetal sheet 7. The spring sheet 6 is stacked on the bimetal sheet 7, and one end of the spring sheet 6 and the bimetal sheet 7 is welded to the contact sheet 5. On the upper side, the middle part of the spring sheet 6 and the bimetal sheet 7 is supported on the base 3, and the other end of the spring sheet 6 is provided with a movable contact 8 which is matched with the static contact 4.

[0012] Two horizontally arranged pins 9 are provided in the open end of the housing 1, one pin 9 is electrically connected to the metal bottom plate 2, and the other pin 9 is electrically connected to the bimetallic strip 7. The op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com