Modified nanometer raw lacquer and preparation method thereof

A non-toxic lacquer and manufacturing method technology, applied in the direction of coating, etc., can solve the undiscovered problems of raw lacquer performance research and patent literature, and achieve the effect of overcoming allergies, expanding the scope of application, and high adhesion of the paint film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

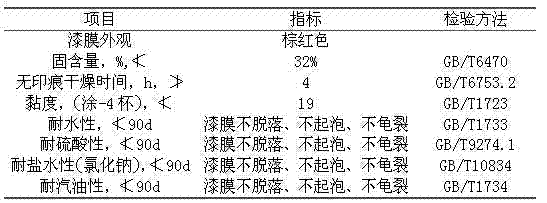

Image

Examples

Embodiment 1

[0037] In the novel nano-modified raw lacquer of the present embodiment and preparation method thereof, the mass percent of each component is as follows:

[0038]

[0039] According to the above mass ratio formula, the urushiol is selected to be extracted from one or more paints produced in Ankang paint, Hanzhong paint, Chengkou paint, Maoba paint, Qinling paint or other areas, and the frying pan fraction is more than 65%. Urushiol content is more than 50%.

[0040] According to the above mass ratio formula, the urushiol solution was heated to 60°C, kept warm, and the formaldehyde was heated to react with the catalyst for 3 hours. After the reaction, the temperature was raised to dehydrate. After dehydration, the temperature of the reactant was lowered to 110°C, and it was ready for use. In addition, add silane coupling agent and absolute ethanol to make a 0.5-1% solution, add nano-silica, disperse with ultrasonic waves for 30 minutes, and dry in an oven for 3-6 hours to ...

Embodiment 2

[0042] In the novel nano-modified raw lacquer of the present embodiment and preparation method thereof, the mass percent of each component is as follows:

[0043]

[0044] According to the above mass ratio formula, the urushiol is selected to be extracted from one or more paints produced in Ankang paint, Hanzhong paint, Chengkou paint, Maoba paint, Qinling paint or other areas, and the frying pan fraction is more than 65%. Urushiol content is more than 50%.

[0045]According to the above mass ratio formula, the urushiol solution was heated to 60°C, kept warm, and the formaldehyde was heated to react with the catalyst for 3 hours. After the reaction, the temperature was raised to dehydrate. After dehydration, the temperature of the reactant was lowered to 110°C, and it was ready for use. In addition, add silane coupling agent and absolute ethanol to make a 0.5-1% solution, add nano-silica, disperse with ultrasonic waves for 30 minutes, and dry in an oven for 3-6 hours to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com