Shell-pulp separator

A technology of separator and pulp, which is applied in the direction of solid separation, grading, and separation of solids from solids with airflow, which can solve the problems of time-consuming, labor-intensive, and large labor costs, and achieve high separation efficiency, reduce labor intensity, and practicality. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

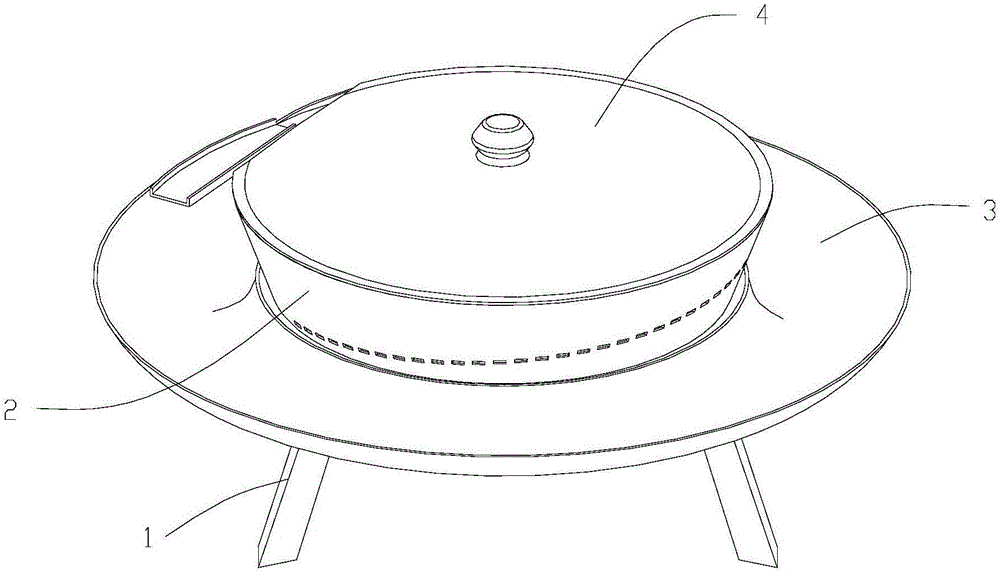

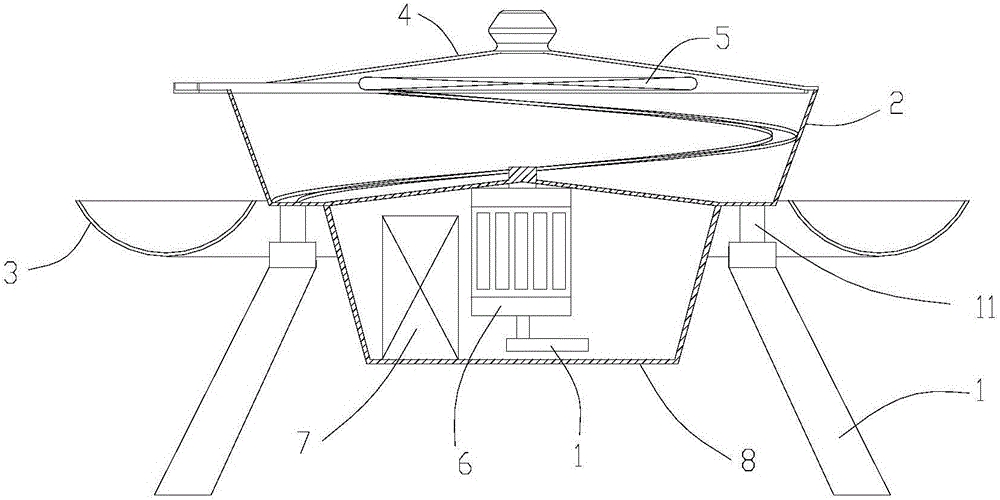

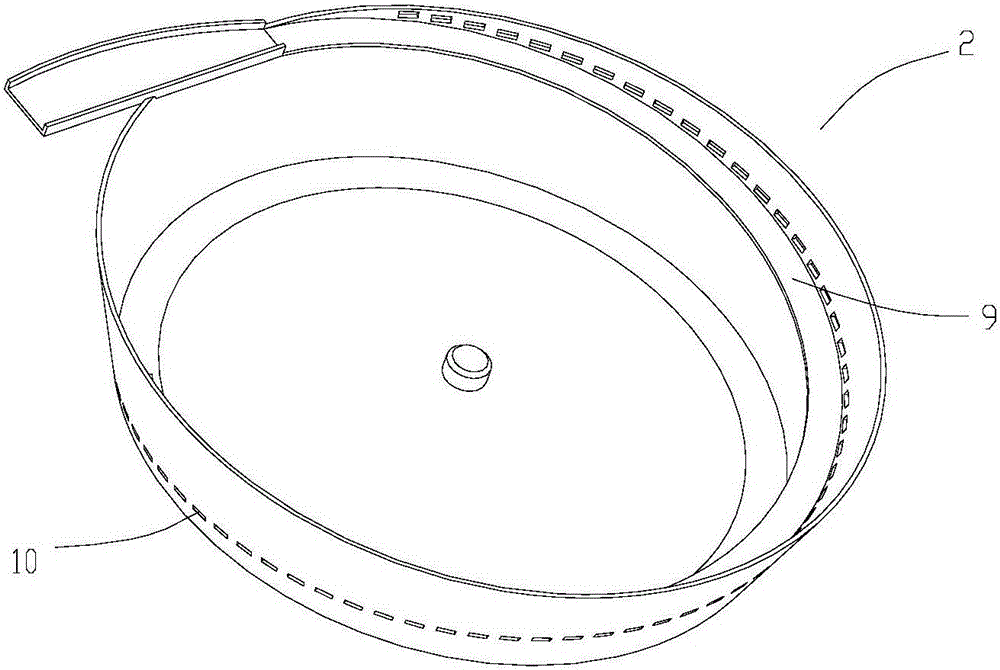

[0030] see Figure 1 to Figure 3 , the invention discloses a fruit shell and pulp separator, comprising a frame 1, a screw tray 2, a vibrating device, a recovery tray 3, a cover 4 and a fan 5; a spring is passed between the spiral tray 2 and the frame 1 Or the resin 11 is elastically installed and connected; the spiral feed tray 2 is disc-shaped, and the bottom surface of the spiral feed tray 2 is an upwardly protruding conical surface, and the edge of the bottom surface is provided with a feeding track 9 that spirals upward from the bottom surface; the vibration device is rigidly installed on the spiral The bottom of the tray 2; the recovery tray 3 is ring-shaped and installed on the bottom outer wall of the spiral tray 2; the cover 4 is set on the top of the spiral tray 2, and the top of the feeding track 9 is exposed outside the cover 4; The blower fan 5 is installed between the cover 4 and the spiral tray 2, and the air outlet direction of the blower fan 5 is vertically do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com