Electric furnace oxidizing slag treatment method

A technology of electric furnace oxidized slag and treatment method, which is applied in the direction of recycling technology, etc., can solve problems such as waste of resources, and achieve the effects of reducing waste, low equipment requirements, and low processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

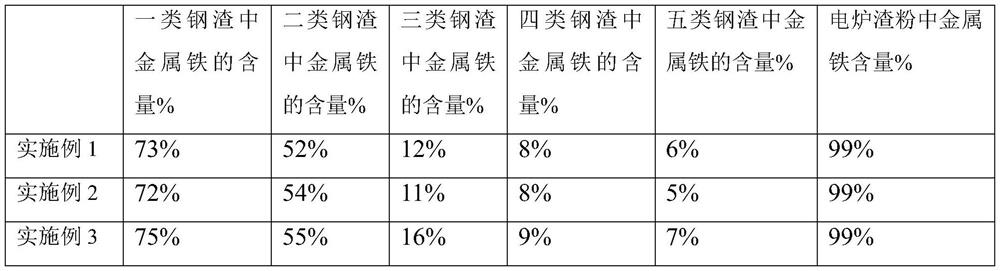

Embodiment 1

[0031] A treatment method for electric furnace oxidized slag, comprising the following steps:

[0032] (1) Put the oxidized slag at a temperature of 800°C into a container and seal it, then evenly spray water mist on the oxidized slag for heat-stuffing treatment, the weight ratio of water consumption to oxidized slag is 0.4:1, keep The pressure inside the container is 0.3MPa, and the stuffy time is 10h;

[0033] (2) Sieve the oxidized slag after heat-stuffing treatment in step (1) with a 200mm sieve, smash and magnetically separate the sieve > 200mm, and the magnetic separation intensity is 4000Gs to obtain a class of steel slag and tailings;

[0034] (3) continue to repeat the operation in step (2) for the tailings in step (2), then carry out magnetic separation to the sieve <200mm, and the magnetic separation intensity is 3500Gs to obtain the second-class steel slag and tailings,

[0035] (4) Screening the tailings in step (2) with a 50mm sieve, crushing the tailings > 50m...

Embodiment 2

[0038] A treatment method for electric furnace oxidized slag, comprising the following steps:

[0039] (1) Put the oxidation slag at a temperature of 1100°C into a container and seal it, then evenly spray water mist on the oxidation slag for heat-stuffing treatment, the weight ratio of water consumption to oxide slag is 0.7:1, keep The pressure inside the container is 1MPa, and the stuffiness time is 30h;

[0040] (2) Sieve the oxidized slag after heat-stuffing treatment in step (1) with a 200mm sieve, smash and magnetically separate the sieve > 200mm, and the magnetic separation intensity is 5000Gs to obtain a class of steel slag and tailings;

[0041] (3) continue to repeat the operation in step (2) for the tailings in step (2), then carry out magnetic separation to the sieve <200mm, the magnetic separation intensity is 4000Gs, and obtain the second class steel slag and tailings,

[0042] (4) Screening the tailings in step (2) with a 50mm sieve, crushing the tailings > 50m...

Embodiment 3

[0045] A treatment method for electric furnace oxidized slag, comprising the following steps:

[0046] (1) Put the oxidized slag at a temperature of 950°C into a container and seal it, and then spray water mist evenly on the oxidized slag for heat-stuffing treatment. The weight ratio of water consumption to oxidized slag is 0.6:1. The pressure inside the container is 0.7MPa, and the stuffiness time is 20h;

[0047] (2) Sieve the oxidized slag after heat-stuffing treatment in step (1) with a 200mm sieve, smash and magnetically separate the sieve > 200mm, and obtain a class of steel slag and tailings;

[0048](3) Continue to repeat the operation in step (2) for the tailings in step (2), then carry out magnetic separation to the sieve <200mm, and the magnetic separation intensity is 4000Gs to obtain the second-class steel slag and tailings,

[0049] (4) Screening the tailings in step (2) with a 50mm sieve, crushing the tailings > 50mm and then magnetically separating them with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com