Direct compression molding process method for lens pits of liquid metal spectacles

A liquid metal, die-casting molding technology, applied in the field of liquid metal spectacle frames, can solve problems such as poor welding performance and inability to form, and achieve high-quality mass production and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

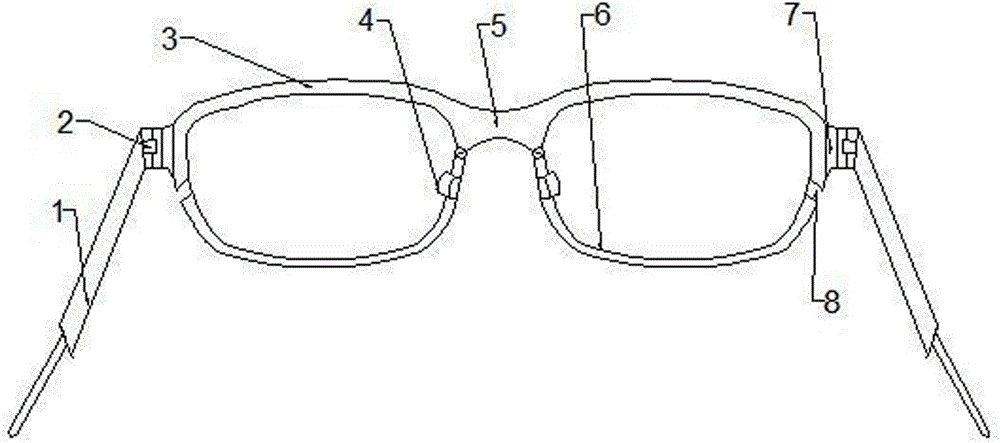

[0017] In the embodiment of the present invention, there is provided a process method of directly molding glasses with chip pits without increasing the machining cost. The glasses include spectacle legs 1, hinges 2, front bezel 3, pipe 4, middle bridge 5, piece pit 6, crown head 7 and front bezel clip 8, such as figure 1 shown.

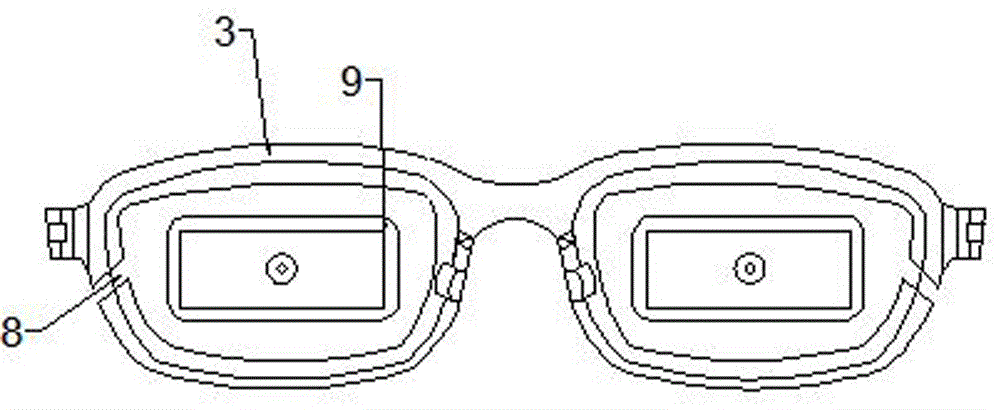

[0018] In order to achieve the above-mentioned purpose, firstly, the dummy 9 is implanted: the dummy 9 made of steel with the shape of the lens is pre-implanted in the mold cavity before molding. During die-casting, chip pits are formed directly. Such as figure 2 shown.

[0019] The concave structure of the crater forms an undercut after molding, which determines the problem that the glasses cannot be demolded after the crater is formed directly on the mold. In order to solve the above problems, secondly, as a replaceable part, the dummy 9 is precisely positioned in the mold cavity through the positioning hole, which ensures the dimensional accur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com