Packing box conveying equipment

A technology for conveying equipment and packaging boxes, applied in the field of packaging box conveying equipment, can solve the problems of inconvenient stacking, achieve the effects of saving manpower, simple overall structure, and improving safety and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

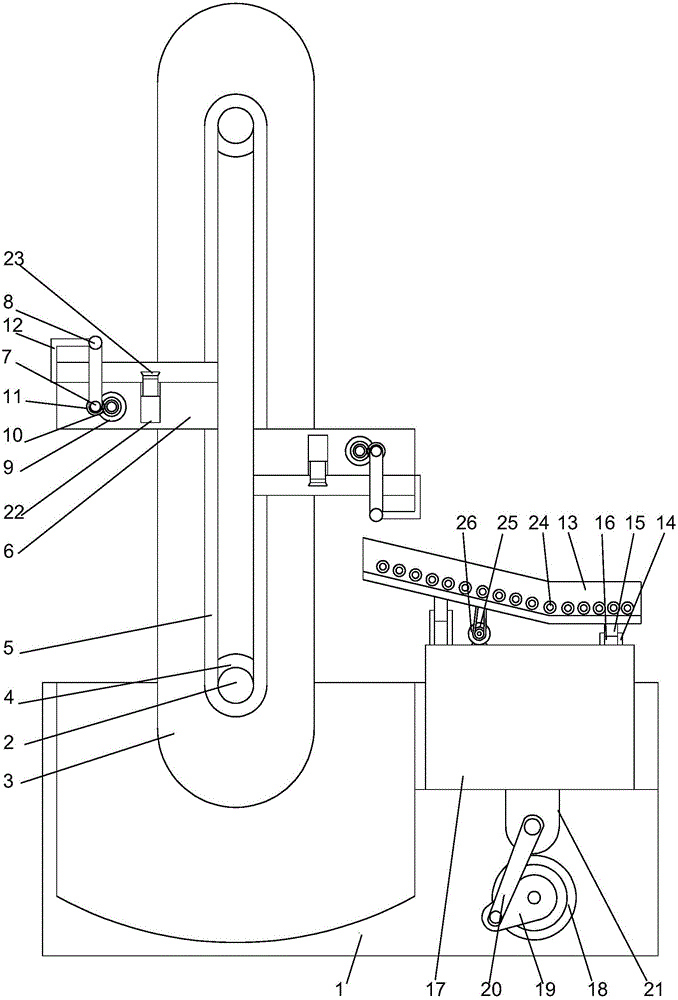

[0024] like figure 1 As shown in the figure, a packaging box conveying device includes a support 1 and two uprights 3 arranged on the support. The upper and lower ends of the two uprights are respectively provided with rotating shafts 2. The ends are respectively provided with sprockets 4, the two sprockets 5 on the same side of the rotating shaft are connected to each other through chains, and a tray 6 is provided on the chain, and one end of the tray is fixedly connected to the chain. superior;

[0025] A chute base 17 is provided above the support, a chute 13 is provided above the chute base, the input end of the chute is located on the side of the column, and the Brackets are respectively provided below the two ends. The brackets include an outer sleeve 14 arranged on the base of the chute and a lifting rod 15 arranged inside the outer sleeve. A vertical lifting rod is arranged below the lifting rod. device 16;

[0026] A first drive motor and a reduction box matching t...

Embodiment 2

[0031]In this embodiment, on the basis of Embodiment 1, in order to make the packaging box more stable on the tray, preferably, a baffle 12 is provided in the middle of the pressing rod, and the baffle is L-shaped, and the One end of the baffle is fixedly connected to the middle of the pressing rod, and the other end of the baffle is located at the outer edge of the tray when the pressing rod is located above the tray. After the packing box is placed on the tray, the pressing rod rotates to the top of the tray to drive the baffle to move.

[0032] In this embodiment, in order to make the structure of the packaging box more stable, a structure for adsorbing the packaging box is provided. Preferably, a counterbore is provided on the tray, and a hydraulic cylinder 22 is provided inside the counterbore. A suction cup 23 is provided on the telescopic rod of the hydraulic rod. When the hydraulic cylinder is in a retracted state, the suction cup is located inside the counterbore, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com