Glass board carrying frame

A technology for glass plates and racks, which is applied in the direction of conveyor objects, furnaces, lighting and heating equipment, etc. It can solve the problems of broken glass plates and staff injuries, so as to avoid pollution and damage, improve the yield rate, and avoid being easily damaged Flip effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and cannot be used to limit the protection scope of the present invention.

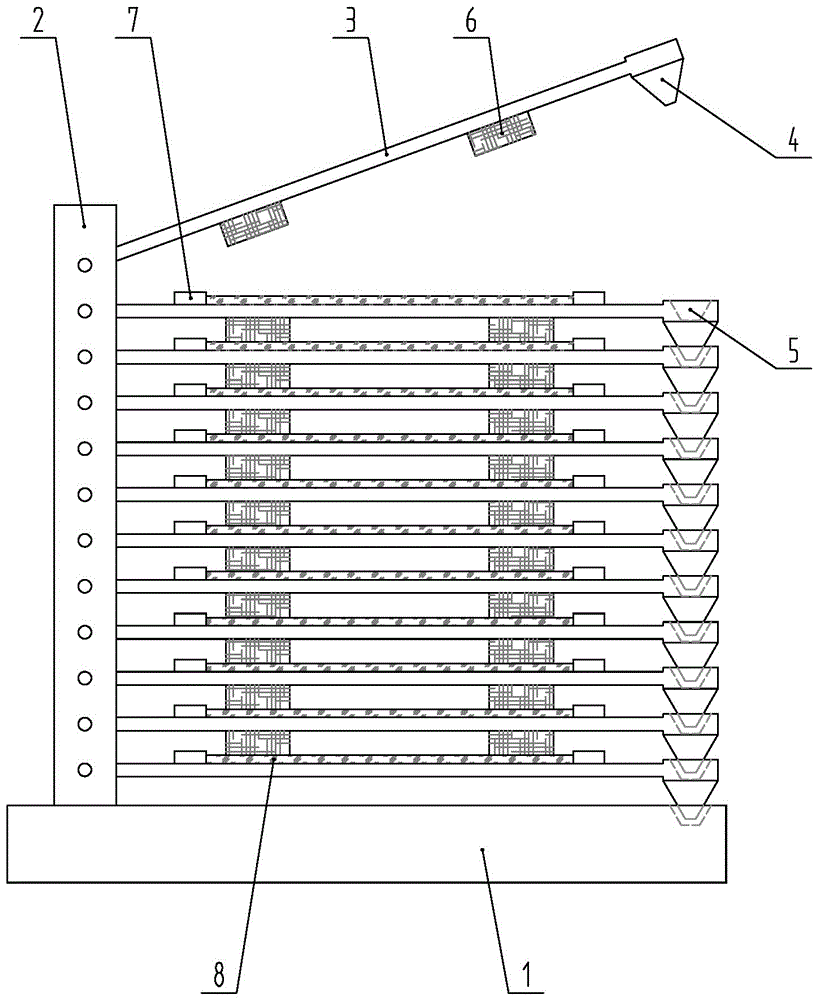

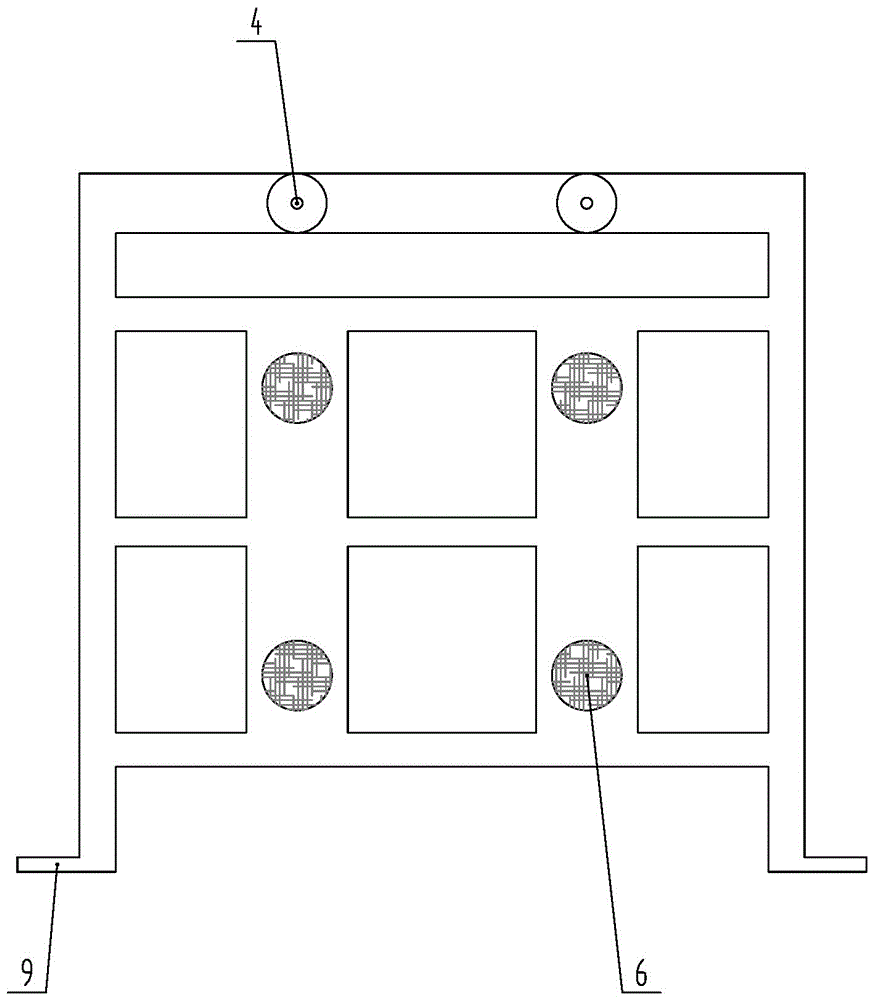

[0021] like figure 1 and 2 As shown, a glass plate placing rack includes a base 1 , a vertical support 2 mounted on the base 1 , and a plurality of movable flat plates 3 hingedly mounted on the vertical support 2 through pins 9 . The movable flat plates 3 are arranged in layers along the height direction. The flat plate at the top layer also serves as a cover plate to protect the glass plate 8 from being scratched, and the top surfaces of the remaining movable flat plates 3 are used for stacking the glass plates 8 . The free end of the movable plate 3 is provided with a plurality of downwardly facing pillars 4 for supporting the movable plate 3 layer by layer. The base 1 and other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com