A kind of preparation method of high tensile strength nylon cs blend film

A high tensile strength, blended film technology, applied in the field of preparation of high tensile strength nylon CS blend film, can solve the problems of loss of natural polymer properties, complex process, CS molecular chain scission, etc. Mixing effect, low cost, effect of improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

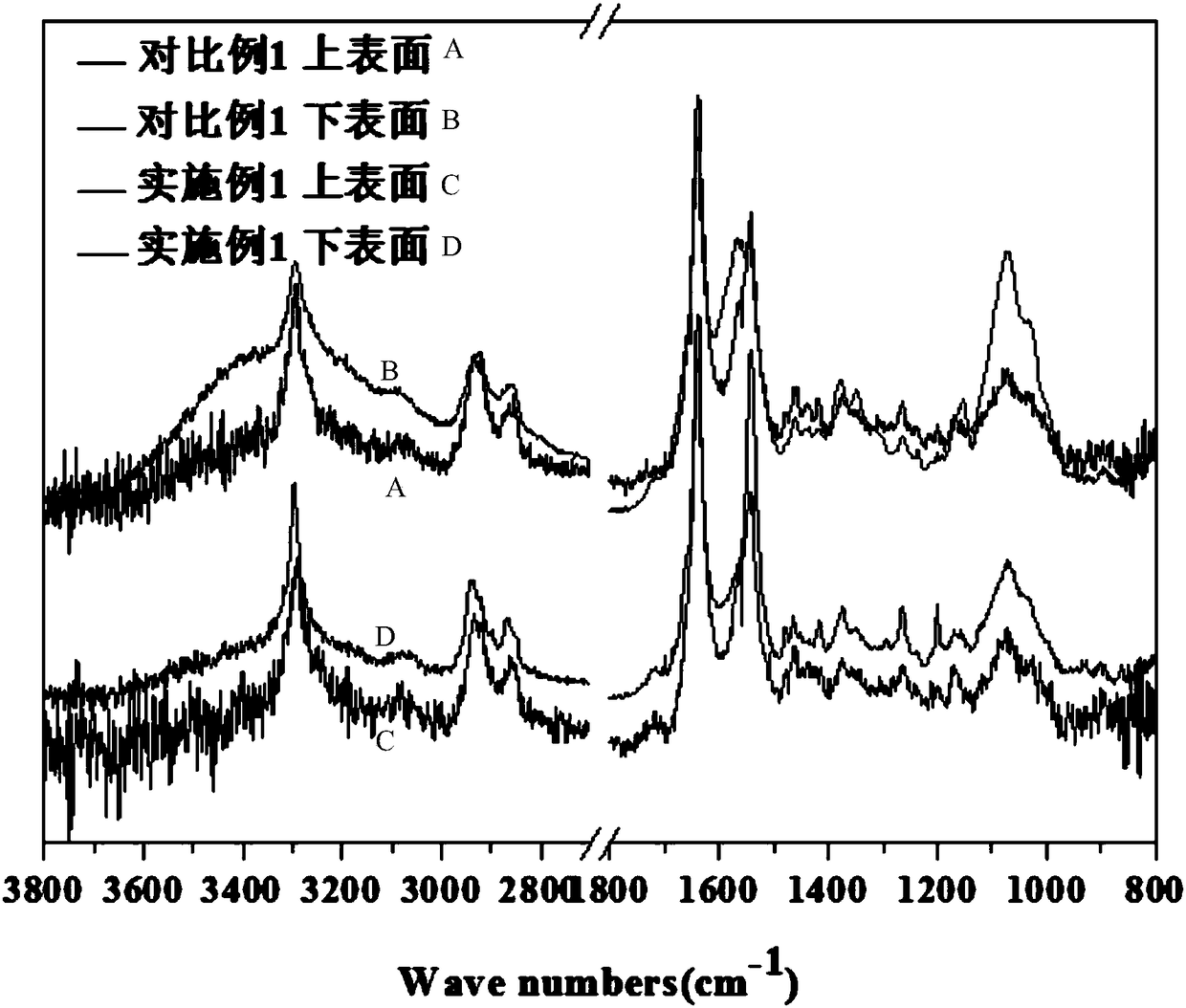

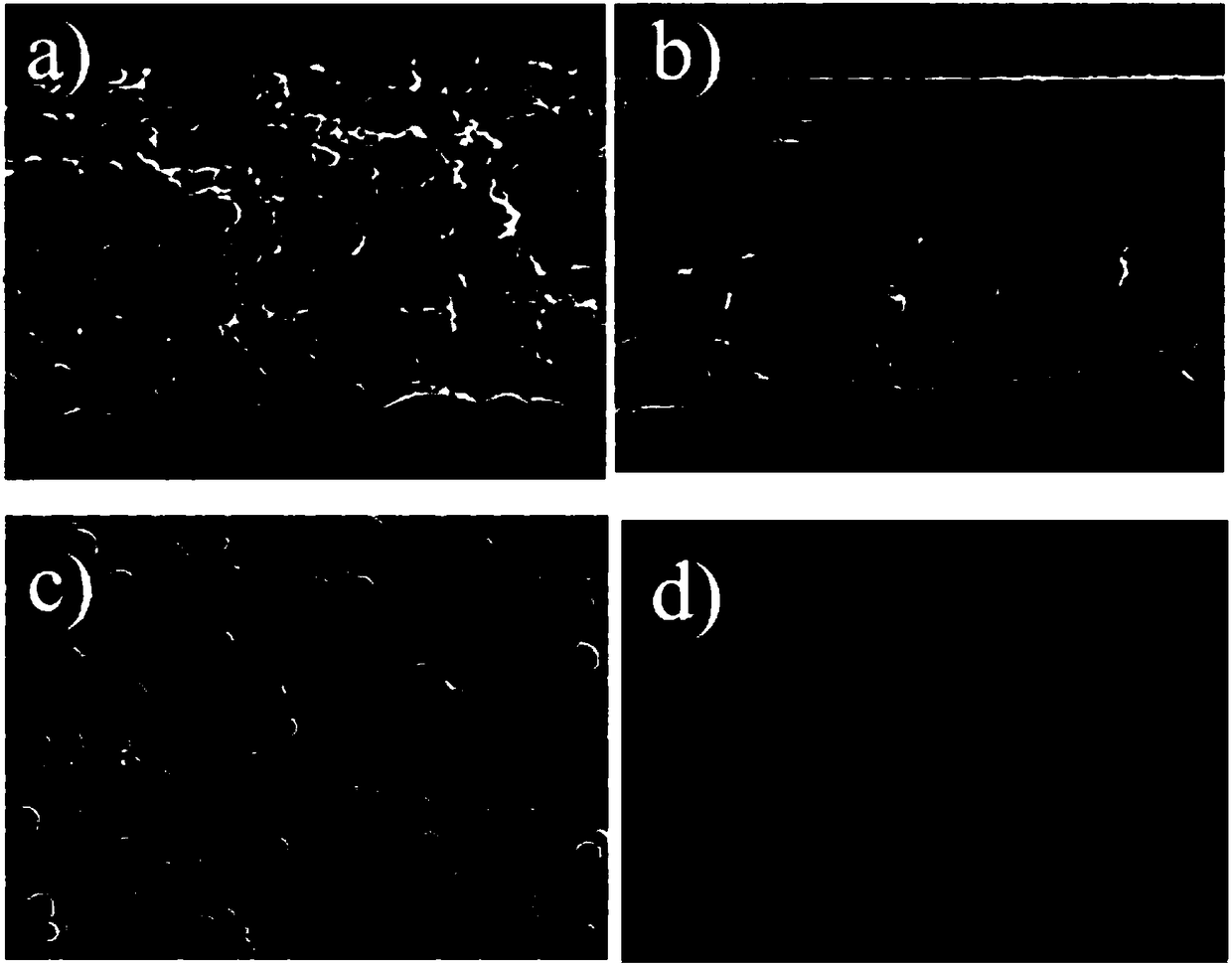

Embodiment 1

[0020] 0.5 g of nylon 6 with a molecular weight of 10000 g / mol was dissolved in 10 ml of formic acid to obtain a film-forming mother solution. Adding chitosan with a molecular weight of 10000g / mol to the mother liquor, a deacetylation degree of 95%, and a weight ratio of chitosan to nylon of 50%, stirred for 24 hours, and stood still for 8 hours; the mother liquor was placed on a conductive film-forming flat plate; the film-forming The flat plate is placed in a parallel plate electric field, and an electric field is applied on both sides of the surface dish. The upper plate of the conductive film-forming flat plate is negatively charged, and the lower plate of the conductive film-forming flat plate is grounded. , frequency 50Hz. After the solvent evaporated, a nylon / chitosan blend film was obtained. The obtained blend film has a tensile strength of 100 MPa and an elongation at break of 75%.

Embodiment 2

[0026] 0.5 g of nylon 66 with a molecular weight of 100,000 g / mol was dissolved in 500 ml of formic acid to obtain a film-forming mother solution. Adding chitosan with a molecular weight of 200000g / mol to the mother liquor, a deacetylation degree of 70%, and a weight ratio of chitosan to nylon of 10%, stirred for 72 hours, and stood still for 4 hours; the mother liquor was placed on a conductive film-forming flat plate; the film-forming The flat plate is placed in a parallel plate electric field, and an electric field is applied on both sides of the surface dish. The upper plate of the conductive film-forming flat plate is negatively charged, and the lower plate of the conductive film-forming flat plate is grounded. The AC voltage field strength is 30kV / m, and the electric field frequency is 0.01Hz. After the solvent evaporated, a nylon / chitosan mixed film was obtained. The tensile strength of the obtained composite film reaches 215MPa, and the elongation at break reaches 175%...

Embodiment 3

[0028]0.5 g of nylon 1010 with a molecular weight of 1000 g / mol was dissolved in 0.5 ml of formic acid to obtain a film-forming mother solution. Adding molecular weight to mother liquor is 2000g / mol chitosan, degree of deacetylation is 80%, the weight ratio of chitosan and nylon is 90%, after stirring for 72h, stand still for 6h; Mother liquor is placed on conductive film-forming plate; The flat plate is placed in a parallel plate electric field, and an electric field is applied on both sides of the surface dish. The upper plate of the conductive film-forming flat plate is negatively charged, and the lower plate of the conductive film-forming flat plate is grounded. The AC voltage field strength is 0.01kV / m, and the frequency is 200Hz. After the solvent evaporated, a nylon / chitosan mixed film was obtained. The tensile strength of the obtained composite film reaches 95MPa, and the elongation at break reaches 75%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com