Rail installation track cement pouring vehicle

A technology of cement and track, which is applied in the direction of track, track laying, track maintenance, etc., can solve the problems that affect the quality of track installation and construction and appearance quality, the amount of cement pouring, the direction of pouring is difficult to control, and the excessive pouring of cement. The effect of labor intensity, saving manpower, simple and flexible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

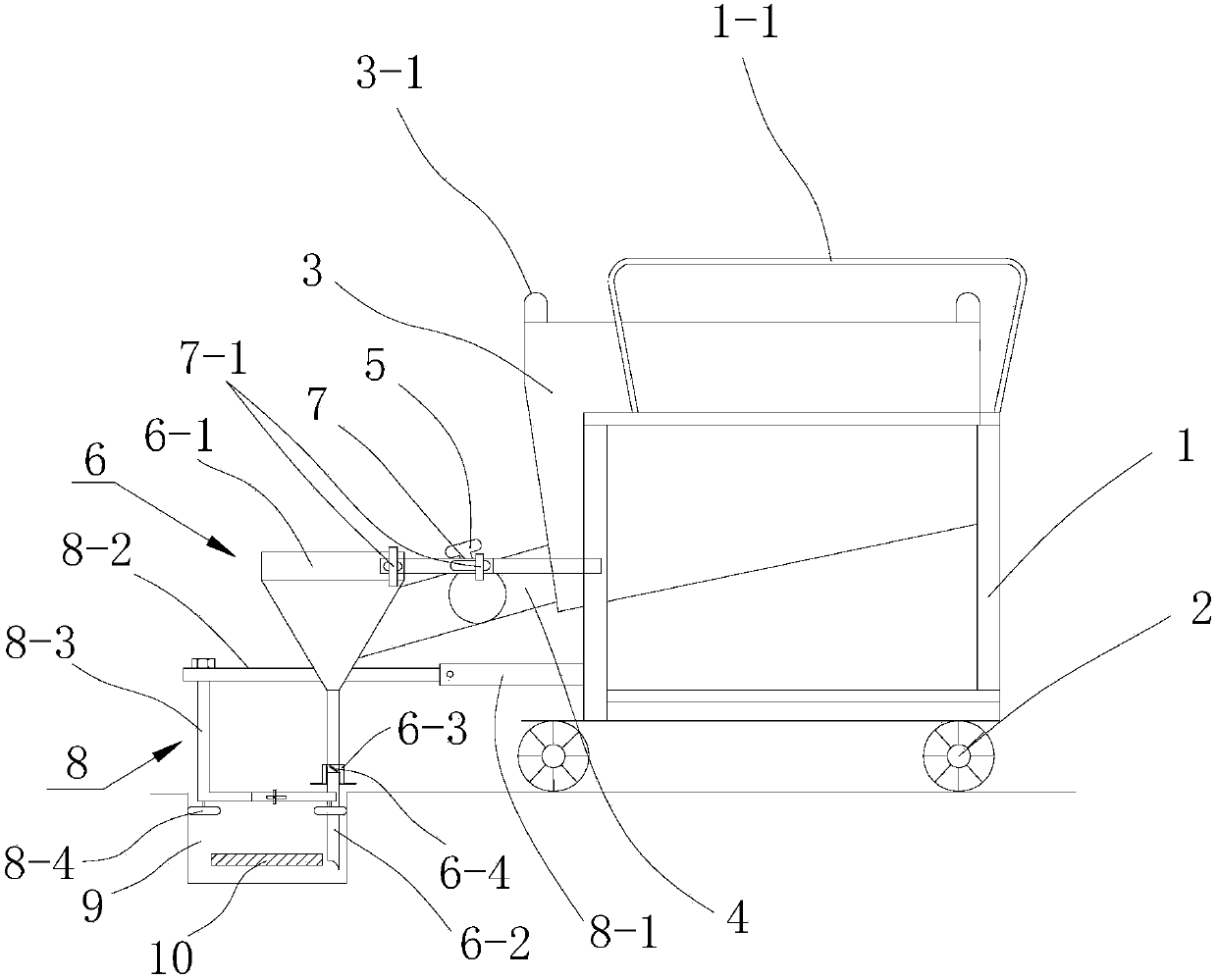

[0016] see figure 1 , a kind of rail installation track glue pouring car, comprising a vehicle frame 1, the universal wheel 2 installed at the bottom of the frame, the universal wheel can be used to arbitrarily adjust the walking direction and the angle of the vehicle body on the site; the track glue on the frame is installed The storage bin 3 is used to store the track mastic; the front end of the track mastic storage bin is provided with a mastic guide pipe 4 for transporting the track mastic, and a control valve 5 is installed on the mastic guide pipe for use It is used to control the flow velocity and flow rate of the track mastic; the discharge end of the mastic guide pipe is connected to the pouring funnel device 6 for receiving the tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com