Novel automatic-feeding intelligent cement paint whitewashing machine

A technology of automatic supply and cement paint, applied in construction, building structure, etc., can solve the problems that it cannot be used for cement paint stucco, cannot realize automatic supply of cement paint intelligent stucco, etc., so as to reduce the impact of personnel health and save manpower and material resources. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention and the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

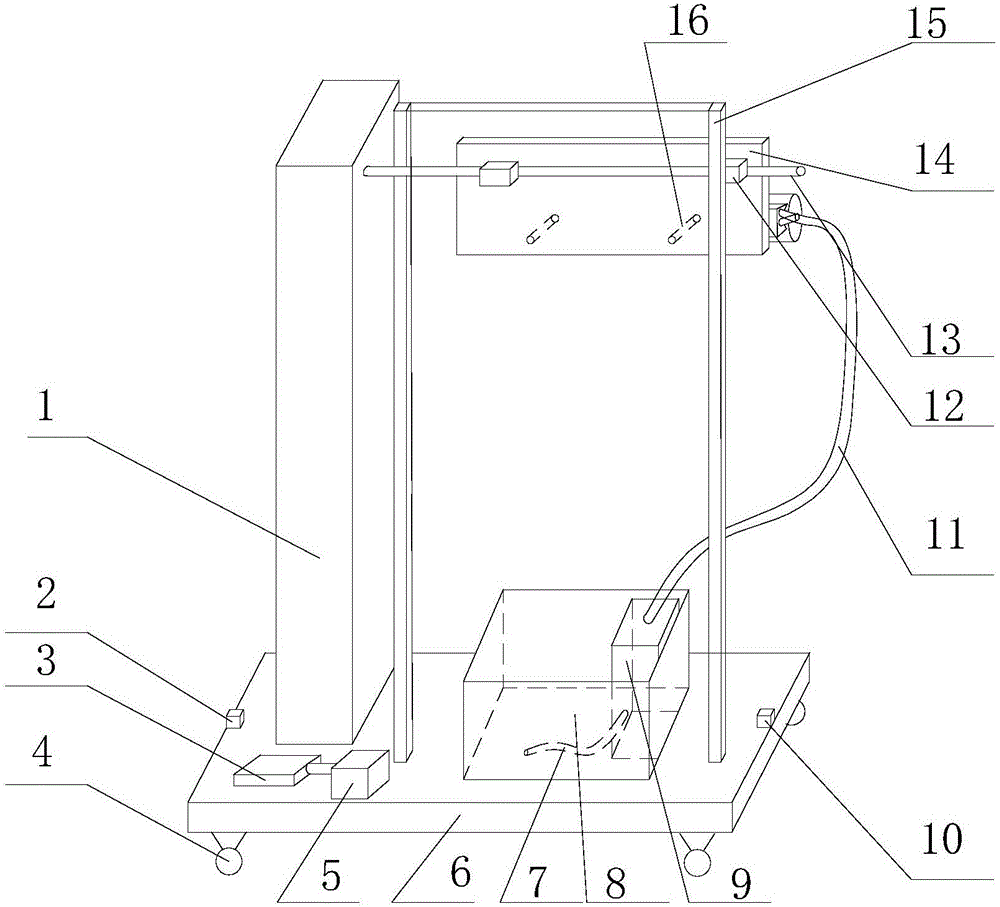

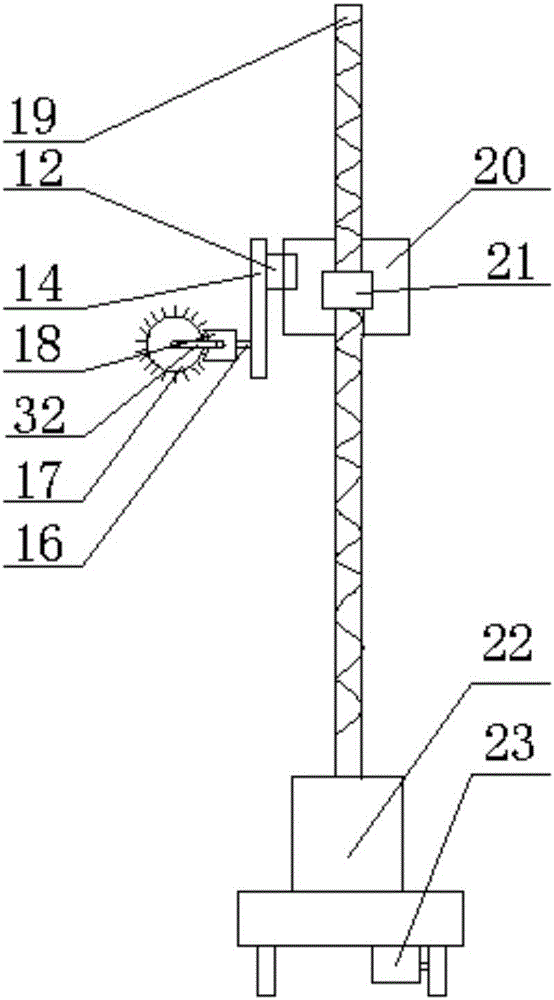

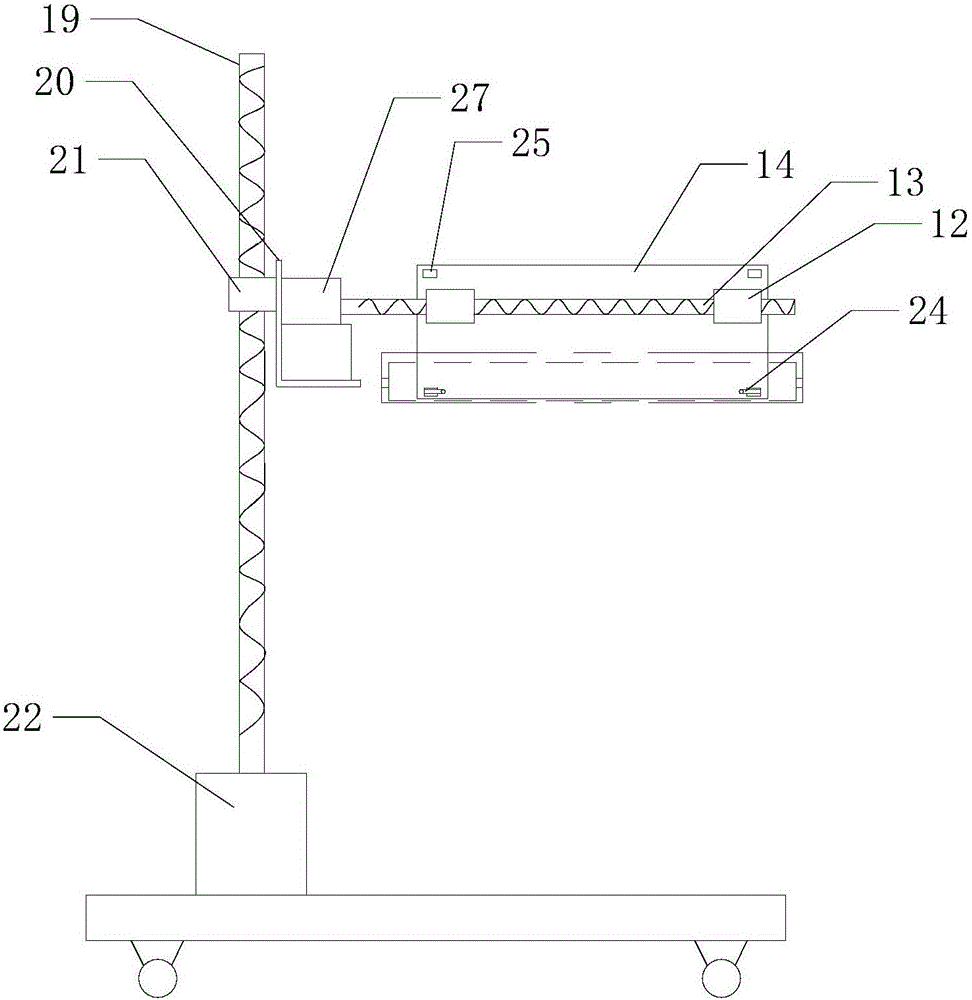

[0022] Such as figure 1 , 2 As shown, a new type of automatic supply type intelligent cement paint painting machine, the feeding method is that the cement paint raw material is placed in the raw material box 8, and the paint pump 9 pumps the raw material into the discharge pipe 11 through the feed pipe 7, and the discharge pipe 11 is connected with the roller. Nozzle 18 communicates, and roller nozzle 18 sprinkles raw material on the painting roller 17, and painting roller 17 touches with the wall, and realizes painting by the kinematic control of left mechanism box 1.

[0023] The new type automatic supply type intelligent cement paint painting machine comprises a mobile trolley 6, the bottom of the mobile trolley 6 is provided with a wheel 4, the wheel 4 is connected with a wheel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com