Belt type cam phaser

A cam phaser and belt-type technology, applied in the direction of machines/engines, engine components, mechanical equipment, etc., can solve parts through holes, timing errors, engine valve mechanism response speed, control accuracy and control stability decline, etc. problems, to achieve the effect of ensuring response speed, preventing external leakage, and eliminating external leakage of powder metallurgy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

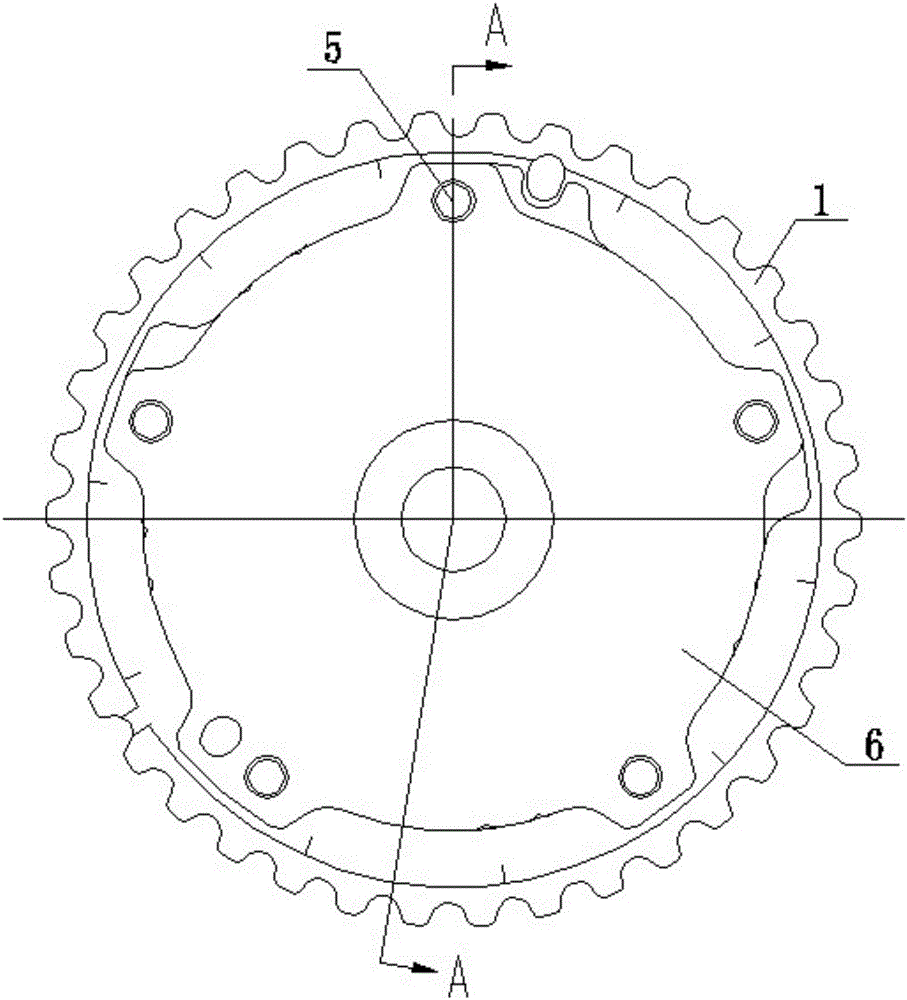

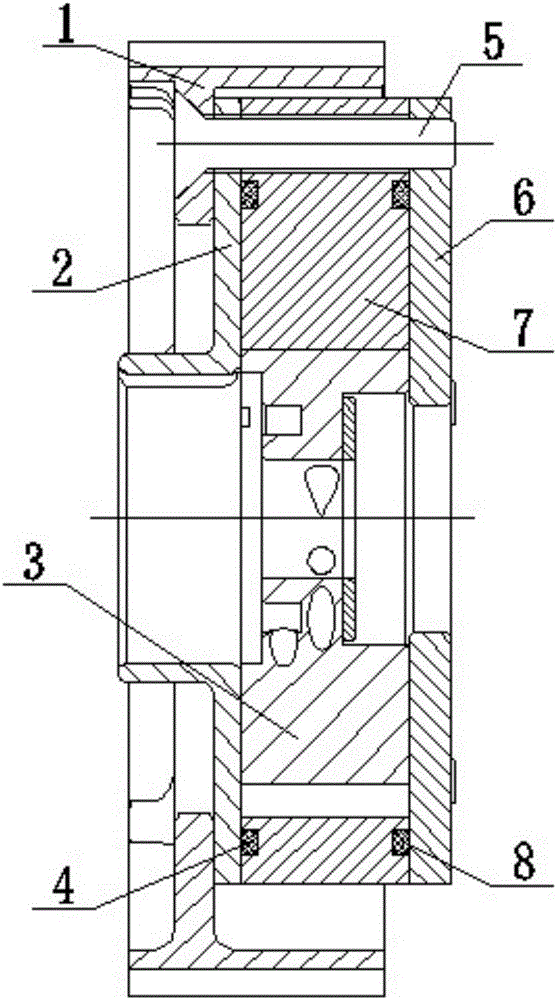

[0024] Such as figure 1 , figure 2 The belt-type cam phaser shown mainly includes a pulley 1, a rear cover 2, a rotor 3 and a shell structure. The shell structure includes a front cover 6 and a housing 7, and the housing 7 is located on the rear cover 2 Between the front cover 6, the pulley 1 is attached to the outside of the rear cover 2, and passes through the pulley 1, the rear cover 2, the housing 7, and the front cover 6 through the first connector 5, and makes the pulley 1, The rear cover 2, the housing 7, and the front cover 6 are fixedly connected into one body, and the housing 7 is connected with the rear cover 2 and the front cover 6 respectively to form a sealed working chamber in a sealed manner, and the rotor 3 is fitted with a clearance installed in the working chamber.

[0025] The first connector 5 preferably adopts screws, which are not only convenient for assembly and disassembly, but also reliable for connection. The housing 7 is preferably an aluminum a...

Embodiment approach 2

[0027] Such as image 3 , Figure 4 The belt-type cam phaser shown mainly includes a pulley 1, a rear cover 2, a rotor 3 and a shell structure. The shell structure includes a front cover 6 and a housing 7, and the housing 7 is located on the rear cover 2 Between the front cover 6, the pulley 1 is attached to the outside of the rear cover 2, and the pulley 1 and the rear cover 2 are fixedly connected through the pulley 1 and the rear cover 2 through the second connecting piece 9, The rear cover 2 , housing 7 , and front cover 6 are fixedly connected together through the third connecting piece 10 through the rear cover 2 , housing 7 , and front cover 6 , and the others are the same as those in Embodiment 1.

[0028] The second connecting piece 9 and the third connecting piece 10 are also preferably made of screws, which are not only convenient for assembly and disassembly, but also reliable in connection. Compared with the belt-type cam phaser in Embodiment 1, the belt-type ca...

Embodiment approach 3

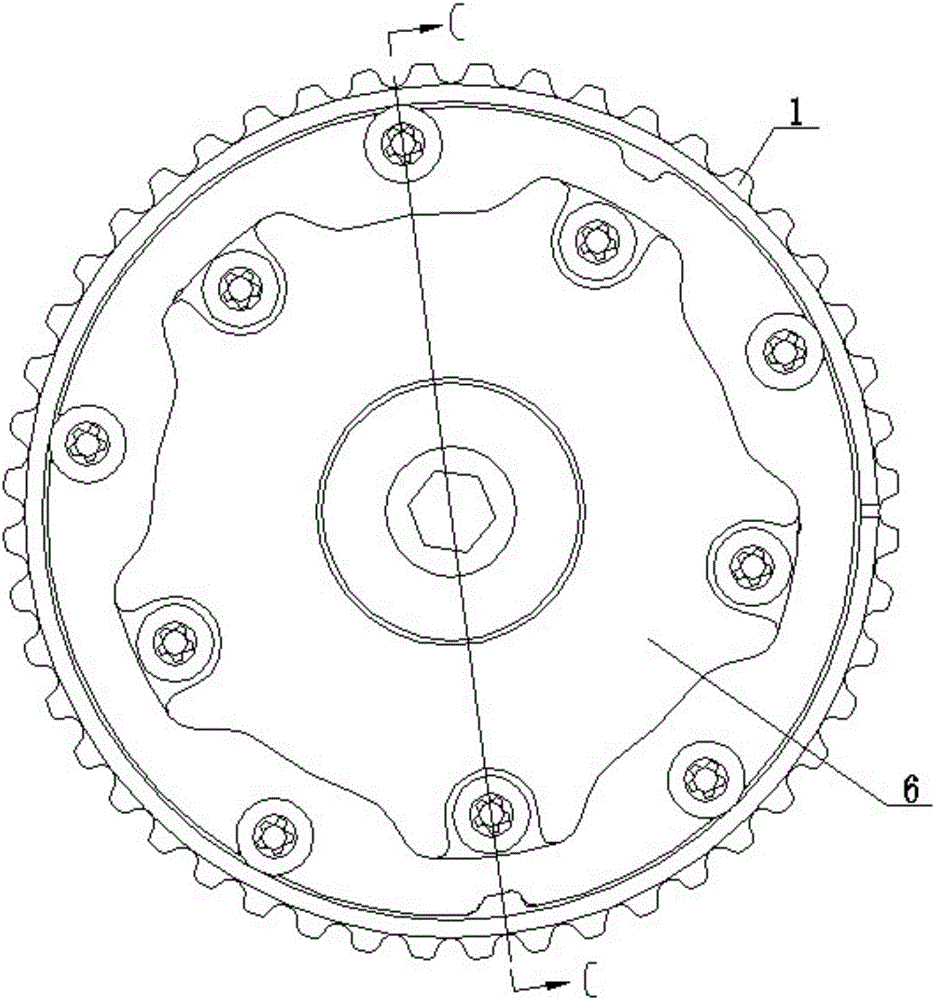

[0030] Such as Figure 5 , Image 6 The belt-type cam phaser shown mainly includes a pulley 1, a rear cover 2, a rotor 3 and a shell structure. The shell structure includes a housing 7, and the housing 7 and the pulley 1 are respectively located on the rear cover 2. The opposite sides, and between the pulley 1, the rear cover 2, and the housing 7 are fixedly connected together through the first connecting piece 5 through the pulley 1, the rear cover 2, and the housing 7; the housing 7 and the rear cover 2 form a sealed working chamber in a sealed connection, and the rotor 3 is installed in the working chamber in a clearance fit manner. Offer a groove on the contact end face of the housing 7 that is in contact with the rear cover plate 2, and install the first sealing ring 4 in the groove, as Image 6 As shown, by adding the first sealing ring 4 at the contact position between the rear cover 2 and the housing 7, the sealing performance between the rear cover 2 and the housing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com