Hexagonal hole cross groove indented bolt

A hexagonal hole and cross technology, applied in the direction of bolts, screws, threaded fasteners, etc., can solve the problems of loose bolts, affecting the normal operation of equipment, inconvenient replacement of parts, etc., and achieve the effect of solving the problem of looseness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

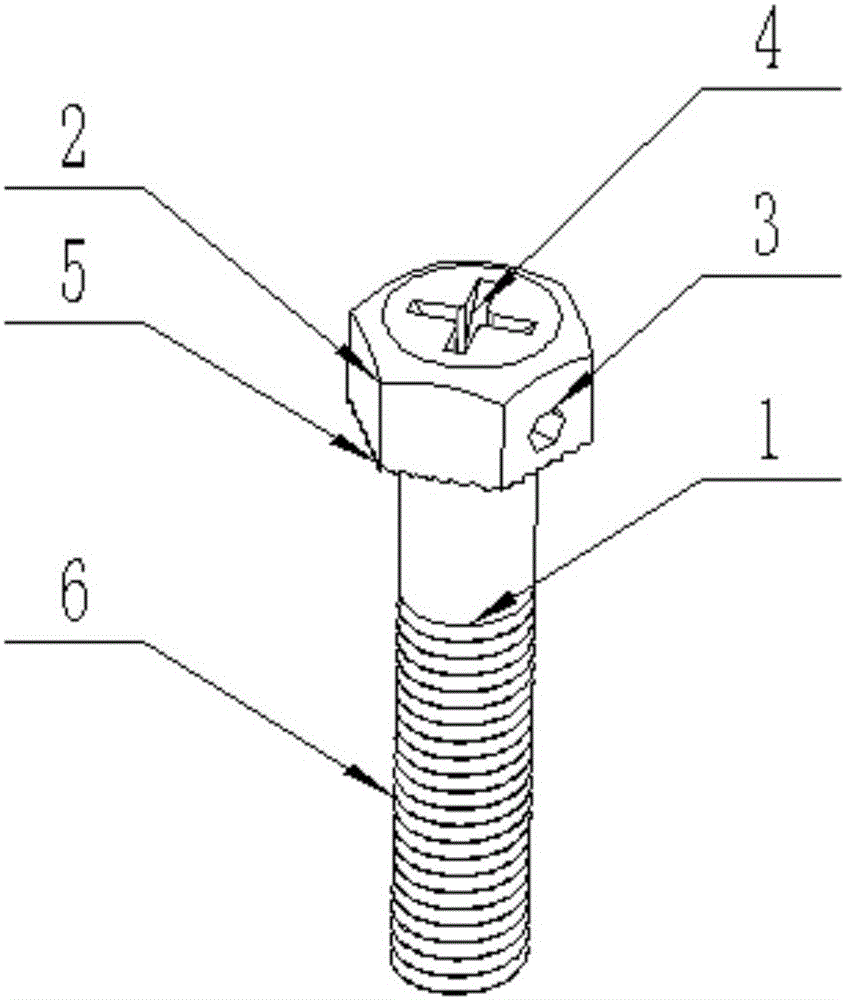

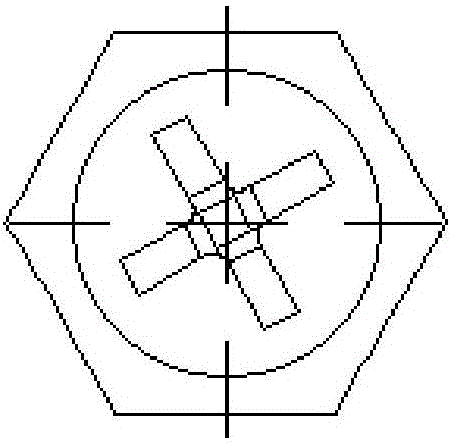

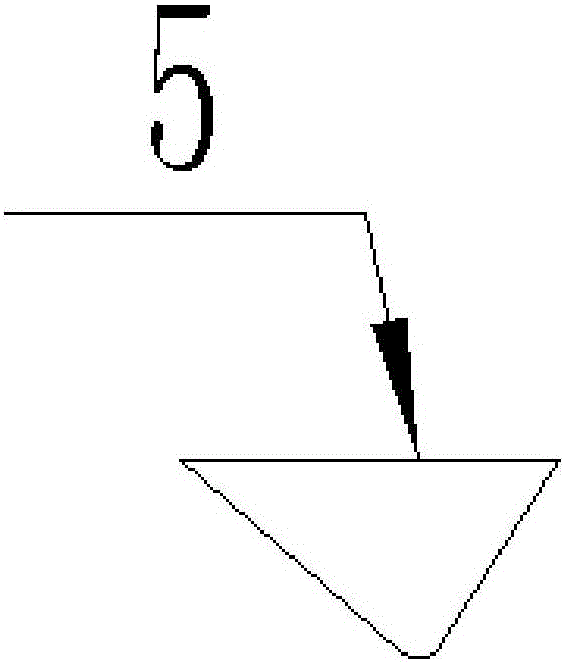

[0016] refer to figure 1 , figure 2 , image 3 and Figure 4 , the present invention is a hexagonal hole cross groove toothed bolt, including a stud 1, a hexagonal prism nut 2, an inner hexagonal hole 3, a cross groove 4, an anti-slip tooth 5 and a thread 6, the stud 1 The shape is a cylinder, the upper end of the stud 1 is a smooth cylinder, the lower end is provided with a thread 6 with a length of 3 / 5 of the total length, the top of the stud 1 is provided with a hexagonal prism nut 2, and the hexagonal prism The upper end surface of the nut 2 is provided with a cross groove 4, and the side surface of the hexagonal prism nut 2 is provided with an inner hexagonal hole 3 with a regular hexagonal cross section, and the lower end surface of the hexagonal prism nut 2 is provided with anti-slip tooth lines. 5. The distance between the two opposite sides of the inner hexagonal hole 3 is 1 / 3 of the height of the hexagonal prism nut 2, the axis of the inner hexagonal hole 3 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com