End cover assembly, gas and liquid separator with end cover assembly and assembly device of end cover assembly

An end cap assembly and end cap technology are used in lighting and heating equipment, refrigeration assemblies, refrigeration and liquefaction, etc., and can solve the problems of reducing the service life of gas-liquid separators, destroying the surface quality of steel plates, and damaging the working performance of compressors. Achieve the effect of avoiding residual welding slag entering the compressor, solving sticking and abrasion, and ensuring anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

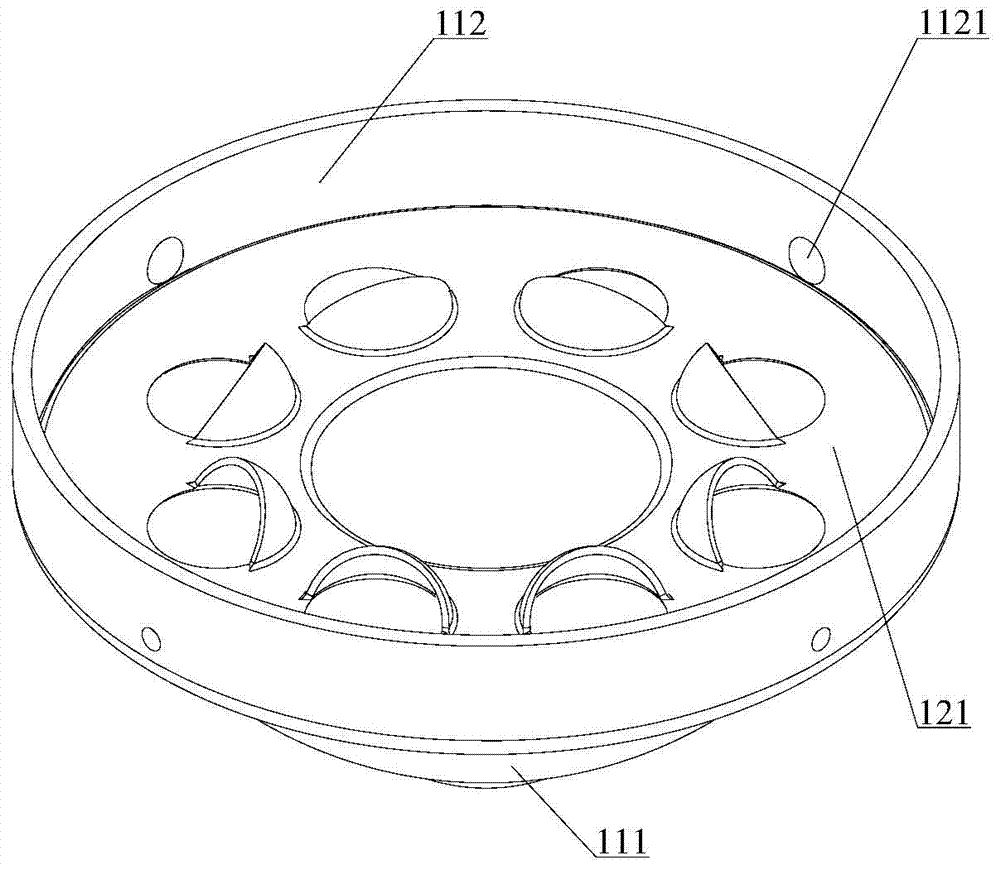

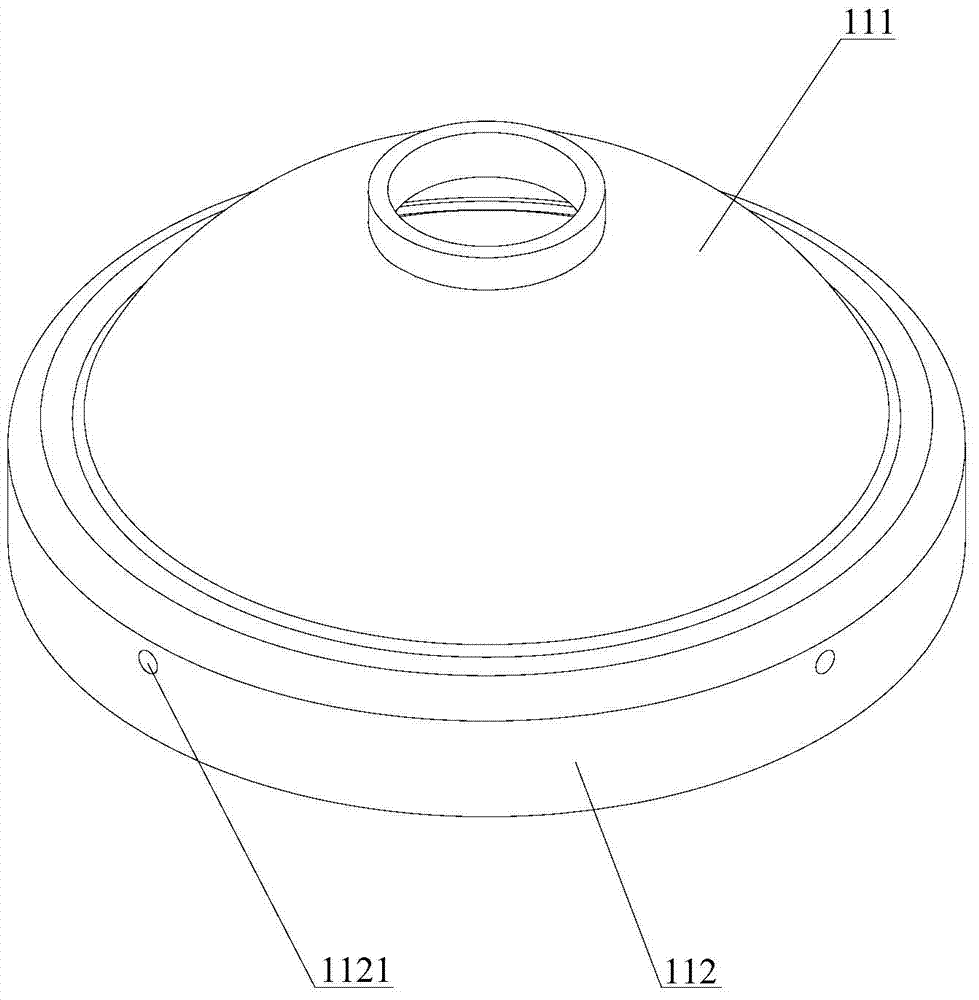

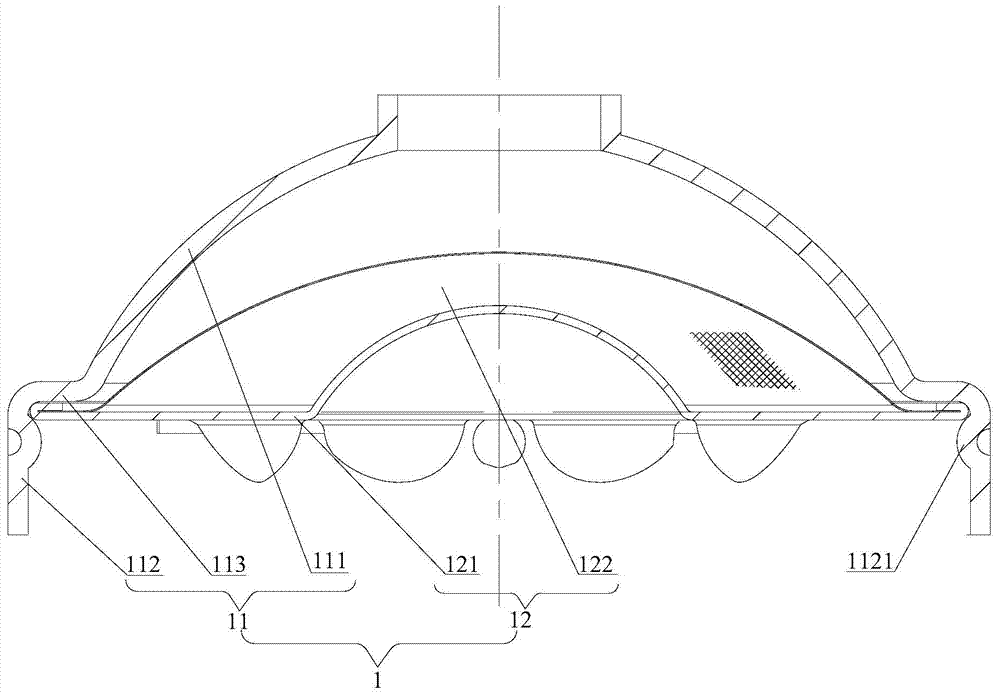

[0050] See figure 1 , figure 2 and image 3 ,in, figure 1 It is a structural schematic diagram of the end cap assembly described in the first embodiment; figure 2 for figure 1 Schematic diagram of the bottom-view structure of the end cap assembly shown; image 3 for figure 2 Cutaway view of end cap assembly shown.

[0051] Without loss of generality, as Figure 1 to Figure 3 As shown, the end cap assembly 1 in this embodiment includes an end cap body 11 and a filter component 12 , and the end cap body 11 and the filter component 12 are fixedly connected. Wherein, the filter component 12 has a filter screen 122 and a filter screen seat 121 fixedly matched with the filter screen 122; the end cover body 11 has a cover body 111 and a flange 112 provided with a locking portion 1121, and the locking portion 1121 is connected to the cover body A fixed section is formed between 111, so that the edge of the filter component 12 is fastened in the fixed section, and the weldin...

Embodiment 2

[0087] See Figure 21 and Figure 22 As shown, among them, Figure 21 It is a schematic structural diagram of the assembly equipment described in the second embodiment; Figure 22 for Figure 21 Schematic diagram of the structure of the positioning table defining the end cap assembly shown in . In order to clearly show the difference between this solution and the first embodiment, components and structures with the same function are marked with the same reference numerals.

[0088] In this embodiment, compared with the first embodiment, the main bodies of the two are exactly the same. The difference is that this solution takes a different approach to the design of the radial limiting section 31 of the positioning platform 3 . Specific as Figure 22 As shown, the radial size of the radial limiting section 31 is larger than the size of the positioning table 3 without the radial positioning section, so that the requirement for the axial dimension of the radial positioning se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com