Sealing process of gas inlet pipe of wsa condenser

A gas inlet and condenser technology, applied in the direction of pipeline protection, protection of pipelines through thermal insulation, hose connection devices, etc., can solve the problems of corrosion and leakage of WSA condenser inlet pipelines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

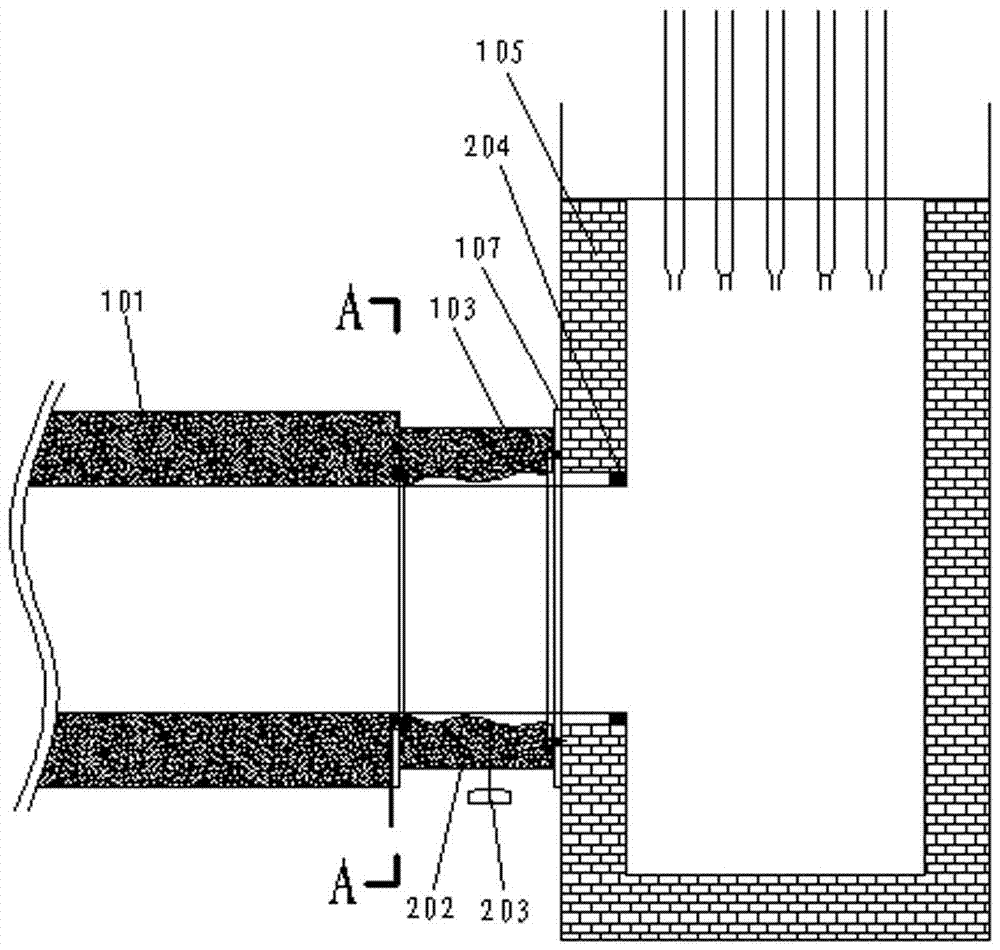

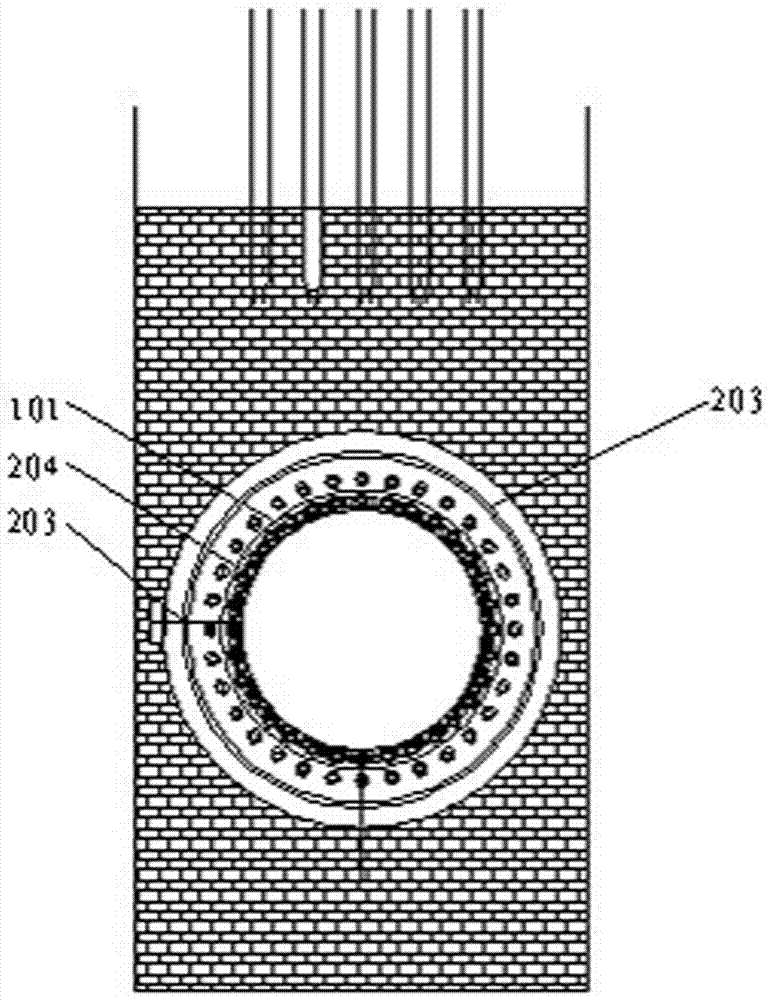

[0015] see figure 1 and figure 2 , a sealing process of WSA condenser gas inlet pipeline, its process steps are:

[0016] The first step: the hard pipe 101 is directly stretched into the process gas inlet of the WSA condenser 105, so that the gas containing high concentration SO 3 The gas is directly delivered to the WSA condenser 105 by the hard pipe 101;

[0017] Step 2: Weld the fixed flange outside the hard pipe 101, socket the soft canvas connection 103 outside the hard pipe 101, and connect the two sides of the soft canvas connection 103 to the flange of the hard pipe 101 and the WSA condenser 105 respectively The outer side of the air inlet reducing flange 107;

[0018] Step 3: Use graphite packing 204 that is resistant to high temperature and acid corrosion on the outside of the nozzle of the hard pipe 101 extending into the WSA condenser 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com