LCD driver board automatic detection method and system

A detection system and detection method technology, applied in the electronic field, can solve the problems of inability to realize automatic detection, easy to burn out the LCD screen, low work efficiency, etc., and achieve the effects of low labor cost, small detection error and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

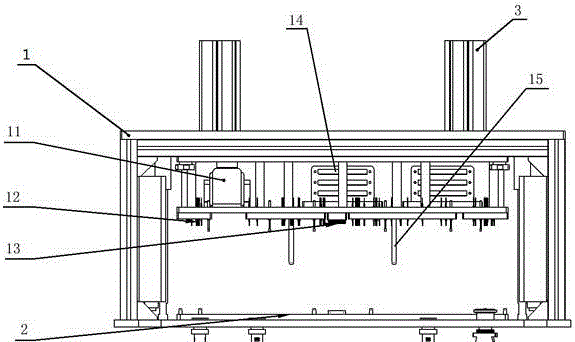

[0058] Embodiment one, such as figure 1 As shown, the LCD driver board automatic detection system includes:

[0059] Upper mold 1, lower mold 2, cylinder 3, industrial computer, image acquisition card, signal generation board, circuit board. The circuit main board is used to control the up and down movement of the cylinder 3, and is also used to process the sensor in-position signal, detect the voltage of the detected LCD driver board, communicate with the industrial computer, and process various external key trigger signals. The cylinder 3 is installed above the upper die 1 to drive the upper die 1 to lift or press down. The lower mold 2 is arranged below the upper mold 1 for fixing the LCD driver board to be tested. A code scanner 11 , a probe 12 , a microneedle 13 and a positioning pin 15 are installed on the bottom surface of the upper mold 1 . The probe 12 is connected with the image acquisition card, and the microneedle 13 is connected with the signal generating board...

Embodiment 2

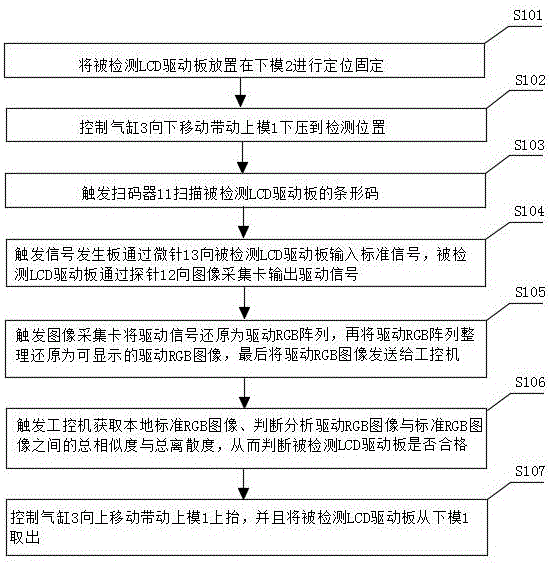

[0063] Embodiment 2, the method for automatic detection of LCD driver board, comprises steps:

[0064] Step S101, placing the LCD driver board to be tested on the lower mold 2 for positioning and fixing.

[0065] After the system is started, the transport device transports the detected LCD driver board to the lower mold 2, and positions and fixes the detected LCD driver board, so as to facilitate subsequent detection of the detected LCD driver board.

[0066] Step S102, controlling the cylinder 3 to move downward to drive the upper mold 1 to press down to the detection position.

[0067] The detection position is specifically the position corresponding to when the lower mold 1 is pressed down to the position where the positioning pin 15 and the lower mold 2 are just positioned.

[0068] The control cylinder 3 moves downward to drive the upper mold 1 to press down, and when receiving the in-position signal from the sensor, the control cylinder 3 stops moving down and stops at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com