Discretized rubber layer photonic crystal shaft with low-frequency vibration-damping characteristics

A technology of phononic crystals and rubber layers, which is applied in the direction of sound-generating devices and instruments, and can solve problems such as difficult engineering applications and single adjustment methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

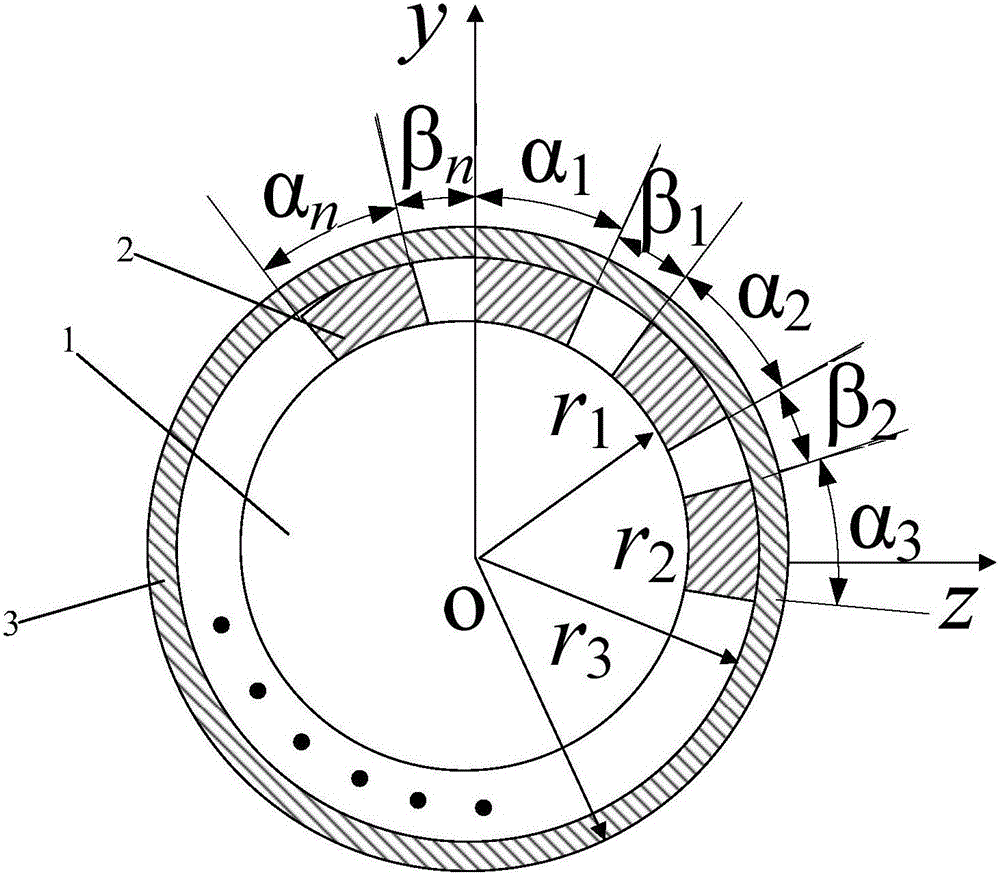

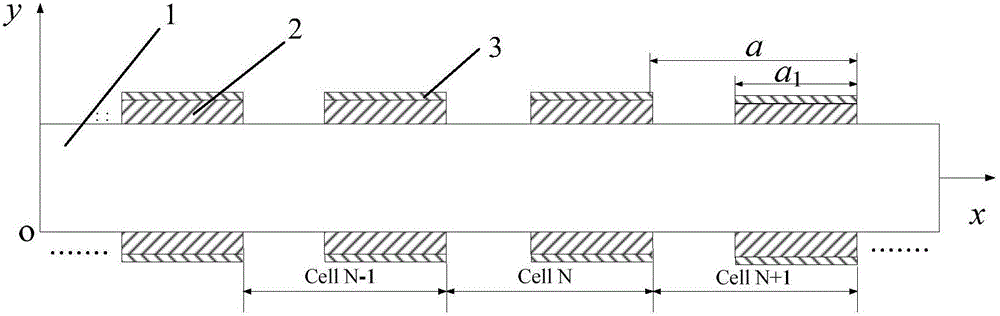

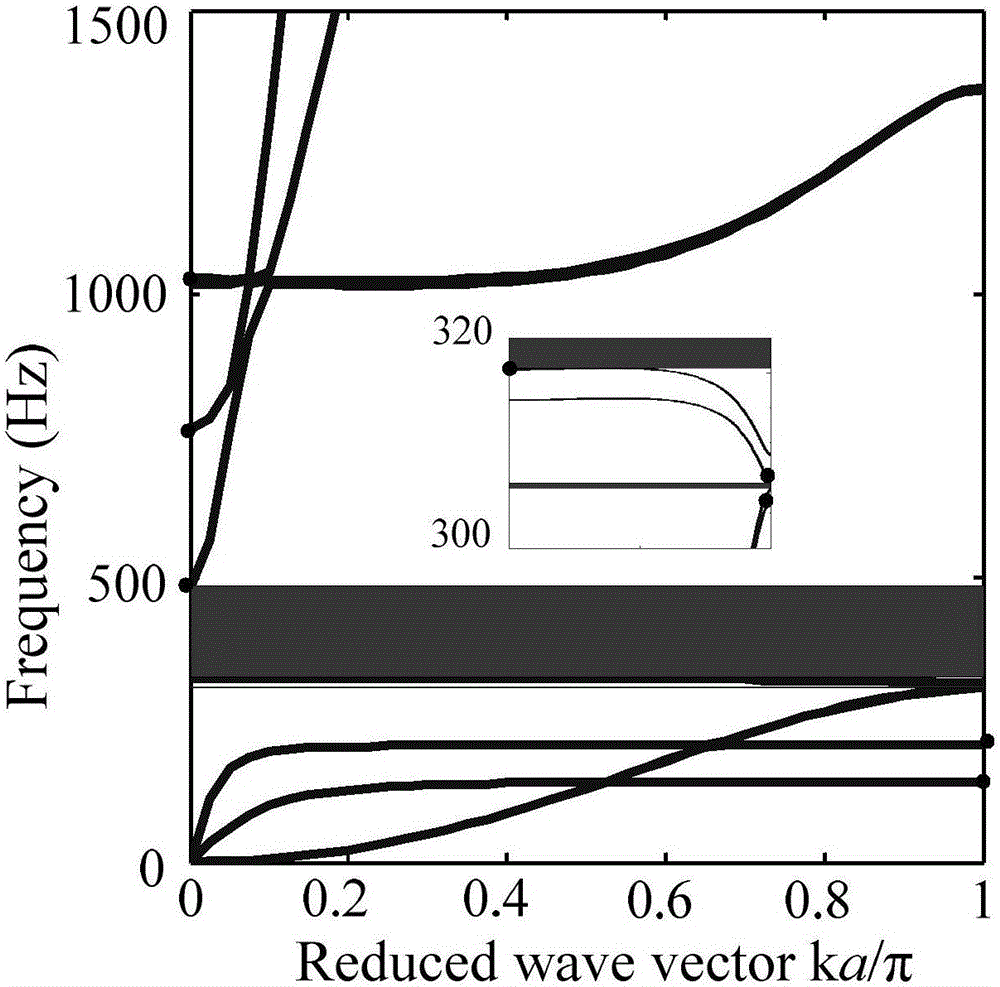

[0027] n=3, α 1 = α 2 = α 3 = β 1 = β 2 = β 3 =60°, in the range of 0-1500HZ, there are two complete band gaps, such as image 3 shown. The first complete bandgap: 308.7-309.4Hz, the second complete bandgap 325.7-487.6Hz. Bending wave band gap: 321Hz-1018Hz, torsional wave band gap 142Hz-763Hz, longitudinal wave band gap 206Hz-488Hz.

[0028] Figure 4 It is the energy band diagram of the traditional phononic crystal axis. It can be seen that there are two complete band gaps at 0-1500 Hz. The first complete band gap is 357.6-442 kHz. The second complete band gap is 484.5-672.8 Hz. The bending wave band gap 357.5-442Hz and 484-1438Hz, torsional wave band gap 197to1018Hz longitudinal wave band gap 270-680Hz.

Embodiment 2

[0030] n=3, α 1 = 30°, α 2 = 60°, α 3 =90°, β 1 = β 2 = β 3 =60°, in the range of 0-1500HZ, there are two complete band gaps. The first complete bandgap: 330-350Hz, the second complete bandgap 369-502Hz. Bending wave band gap: 330Hz-350Hz, 369-870Hz, torsional wave band gap 142Hz-754Hz, longitudinal wave band gap 209Hz-502Hz.

Embodiment 3

[0032] n=3, α 1 = α 2 = α 3 = 10°, β 1 = β 2 = β 3 =110°, the bending wave has the lowest band gap from 128.6 to 319HZ, the longitudinal wave has the lowest energy band gap from 84-201HZ, and the three elastic wave band gaps are the lowest. The lowest energy bandgap of torsional wave is from 44 to 245HZ. The lowest for full bandgap is from 128.6 to 201HZ.

[0033] Visible, adopt structure of the present invention, can make:

[0034] 1. Bandgap drop

[0035] The introduction of the discrete rubber layer makes the first complete bandgap of the new structure decrease and the width is reduced to a state of almost disappearing, and the second bandgap decreases. The discretization of the rubber layer has a great influence on the bending wave, so that the first band gap of the bending wave disappears and the second band gap moves down; while the band gaps of the torsional wave and the longitudinal wave both show a downward trend, and the shape of the dispersion curve is rough...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Section radius | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com