USB C type plug connector

A technology of plug connectors and grounding strips, which is applied in the direction of connecting parts to protect grounding/shielding devices, etc. It can solve the problems of signal crosstalk and affecting signal transmission of conductive terminals, and achieve the effect of improving elastic recovery performance and extending service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

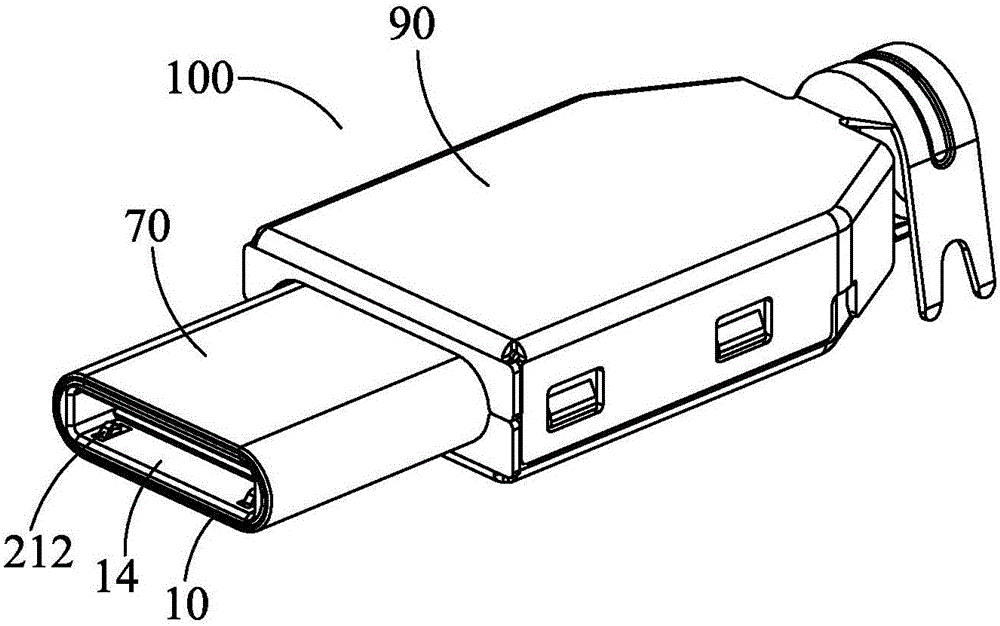

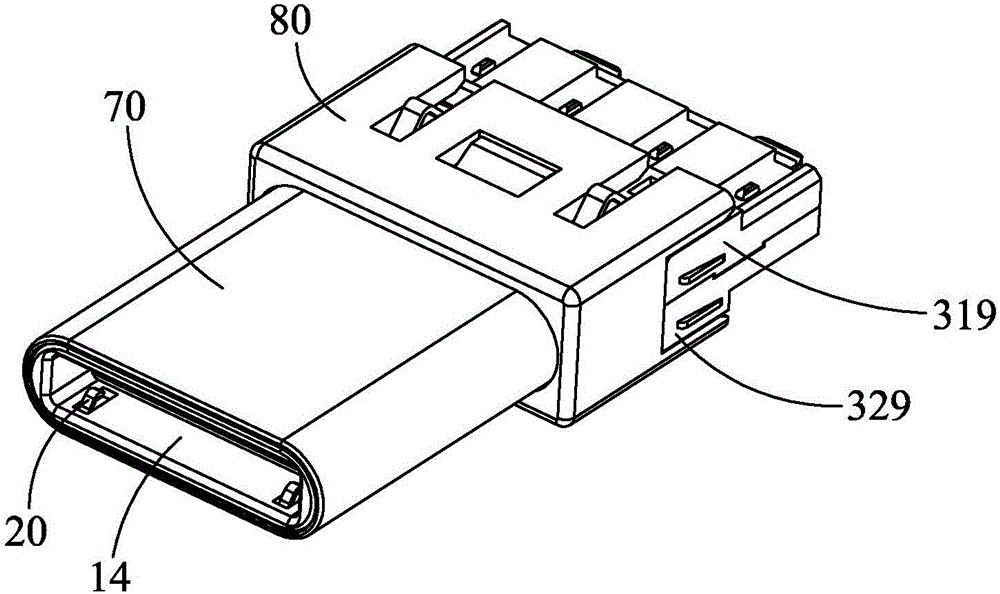

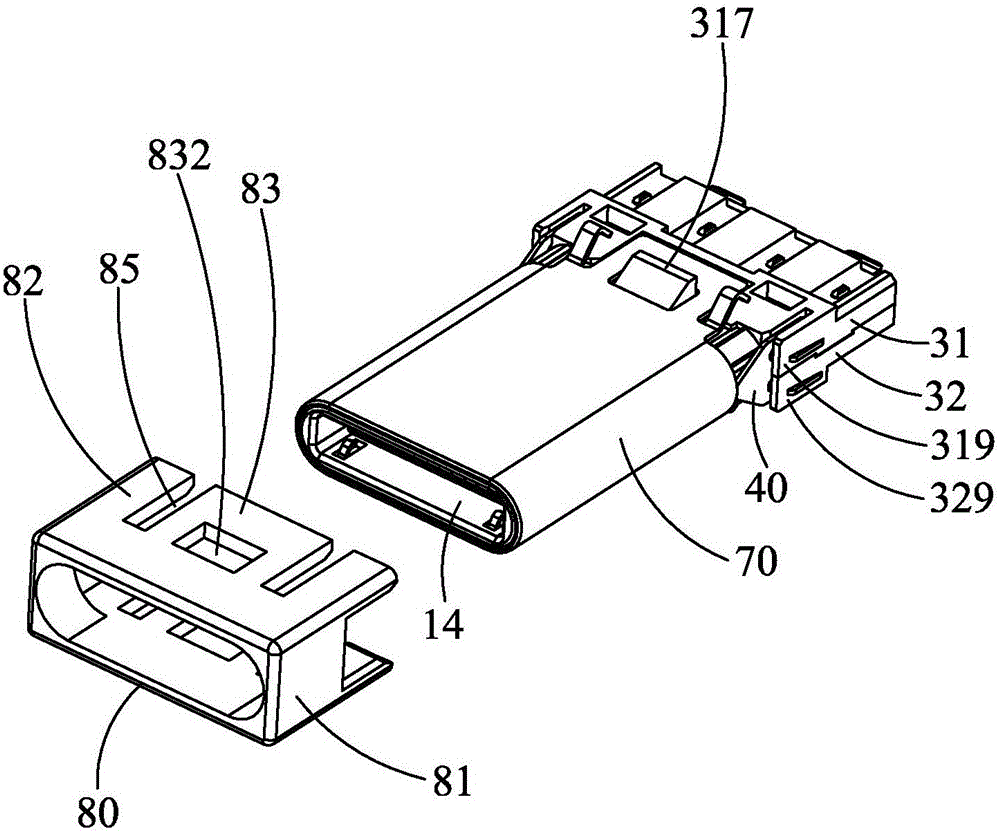

[0026] see Figure 1 to Figure 11 As shown, the USB C-type plug connector 100 of the present invention supports forward and reverse insertion, and is used for docking with a socket connector (not shown), which includes an insulating body 10, two metal grounding plates 20, an upper terminal module 31, The lower terminal module 32, two metal clamping pieces 40, a first metal connecting piece 51, a second metal connecting piece 52, a metal locking piece 60, a front metal shell 70, an insulating sheath 80, and a rear Metal shell 90.

[0027] The insulating body 10 includes a top 11 , a bottom 12 , two side portions 13 , a pair of connecting holes 14 , a fixing space 15 and a partition 16 . The docking hole 14 and the fixing space 15 are formed between the top 11, the bottom 12 and the two sides 13, the docking hole 14 is located in front of the fixing space 15, and the partition 16 is interposed between the docking hole 14 and the fixing space 16, and the partition 16 has A plur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com