Cyclone type dust collector with transverse dust barrel

A vacuum cleaner and cyclone technology, applied in the field of cyclone vacuum cleaner, can solve the problems affecting the appearance and airtightness of the vacuum cleaner, so as to improve the dust collection efficiency and ensure the sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

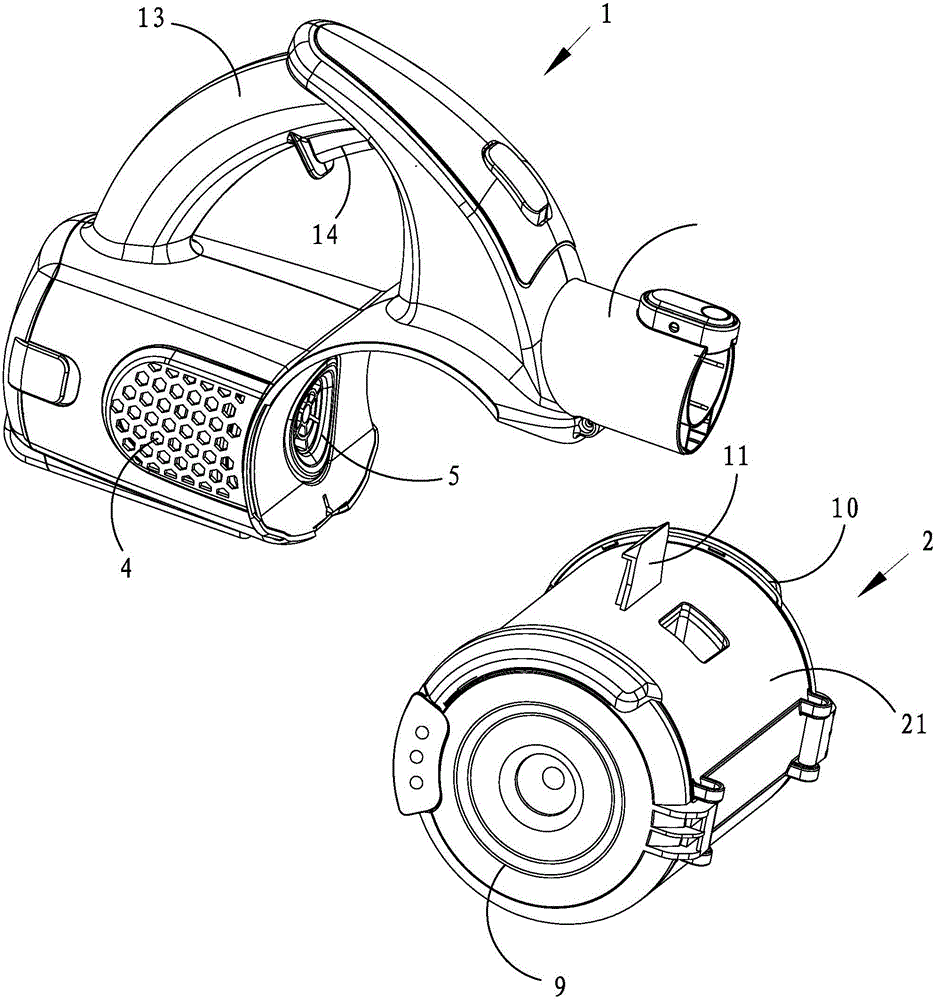

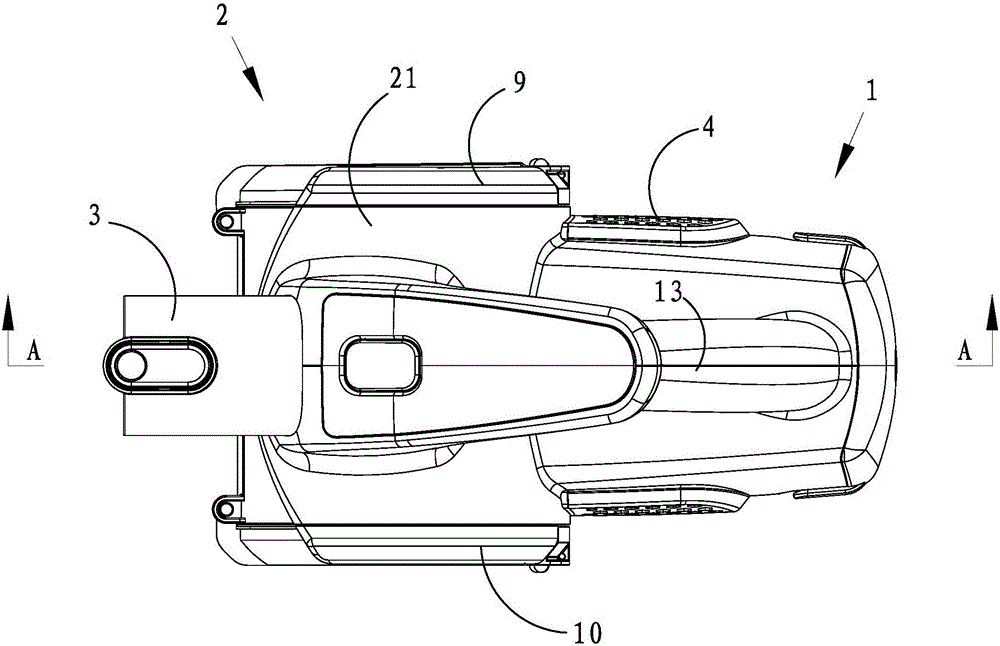

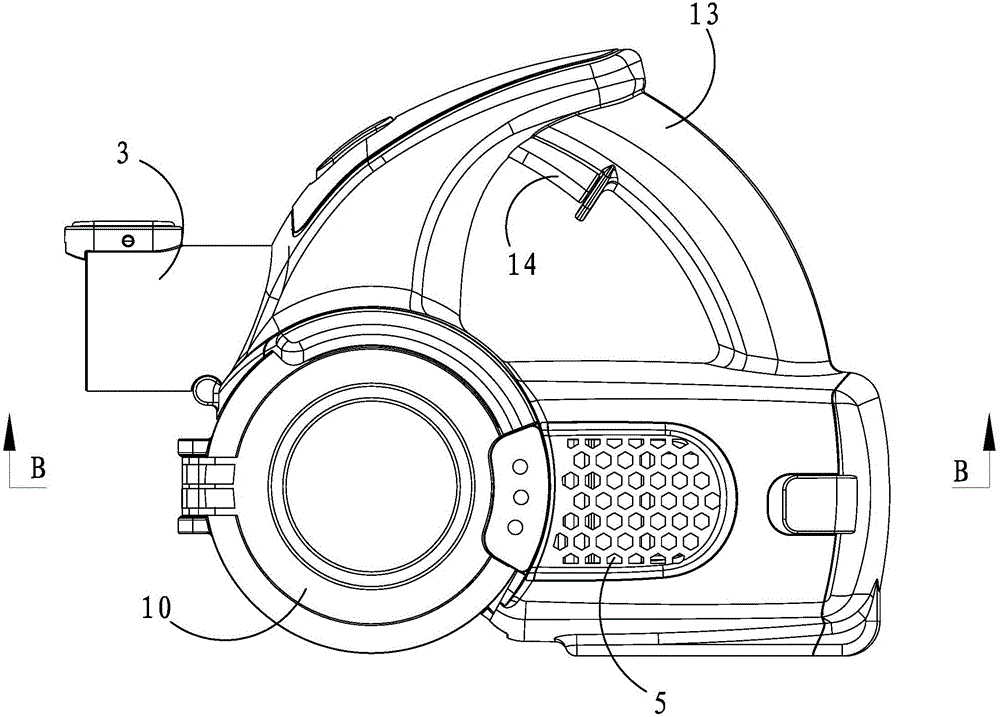

[0025] Example 1: See the attached drawings 1-5 Shown, a dust bucket 2 Horizontal cyclone vacuum cleaner, which includes a vacuum cleaner body 1 And the horizontal dust bucket 2 , The dust bucket 2 With the cleaner body 1 Removable connection, the vacuum cleaner body 1 Including connecting the dust suction pipe and the dust bucket 2 Air inlet channel 3 , One end is connected to the dust bucket 2 The air outlet at the other end communicates with the outside world 4 And set in the air outlet channel 4 Fan inside 5 , Define the vacuum cleaner body 1 Air inlet channel 3 The end is the front and air outlet channel 4 The end is the rear, the vacuum cleaner body 1 Has a left side and a right side, the dust bucket 2 The axis extends along the left and right direction, the dust bucket 2 To the left end of the cleaner body 1 The distance between the left part and the dust bucket 2 The right end to the cleaner body 1 The distance of the right side part is equal, the dus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com