A hanger structure for boiler superheater

A technology of superheater and card holder, applied in the direction of boiler support/positioning device, etc., can solve the problems such as the inability of the guard plate to expand freely, block the flue, structural problems, etc., to solve the problem of connection heat transfer, solve thermal expansion, and achieve stability. fixed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

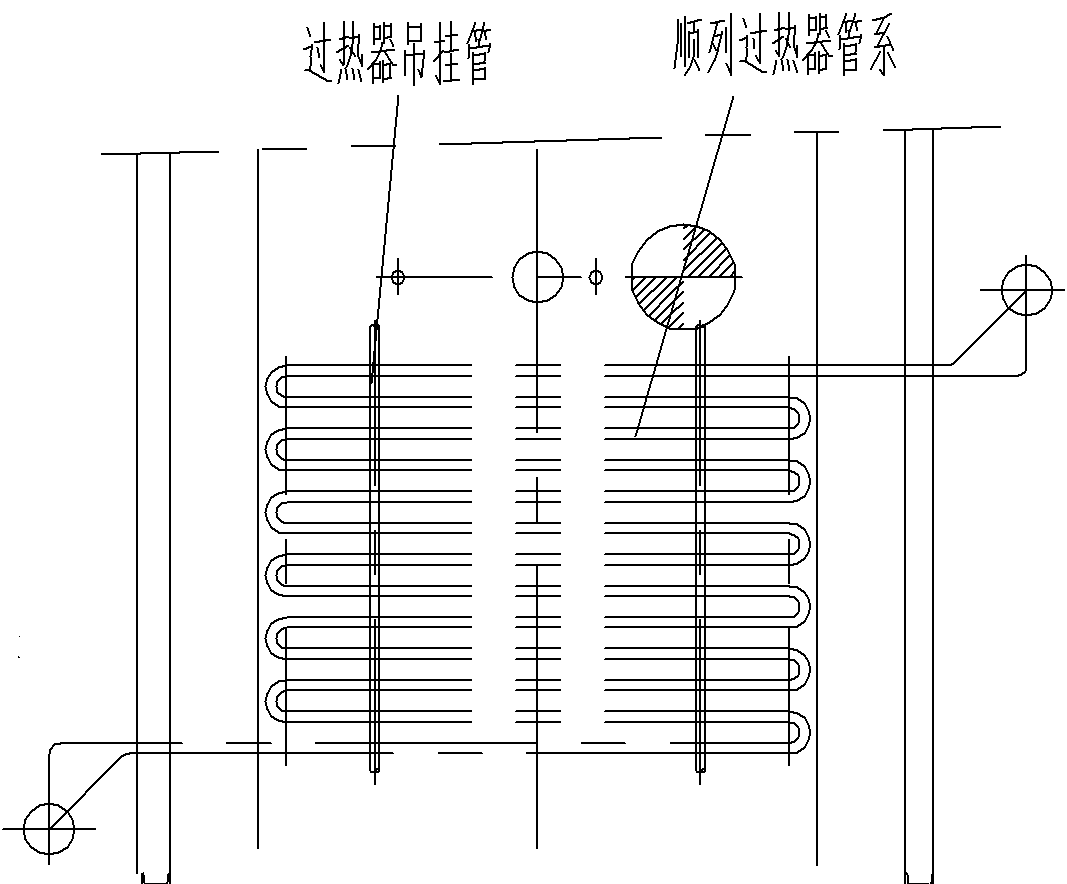

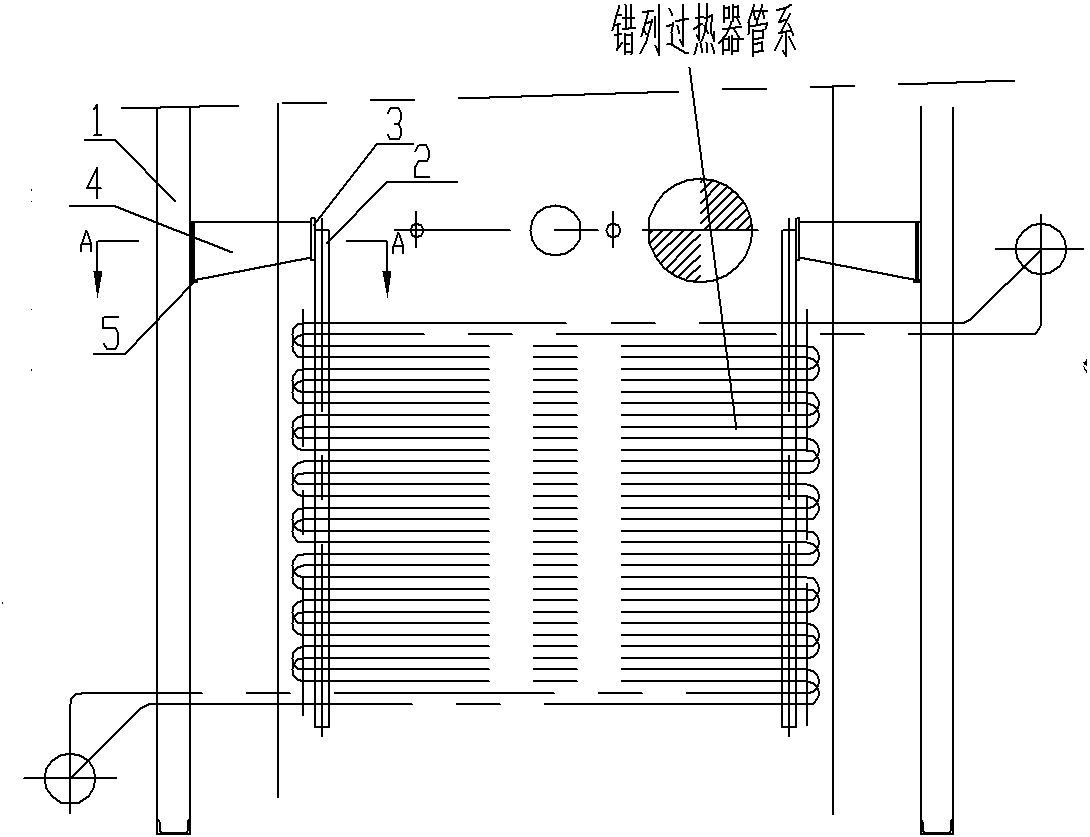

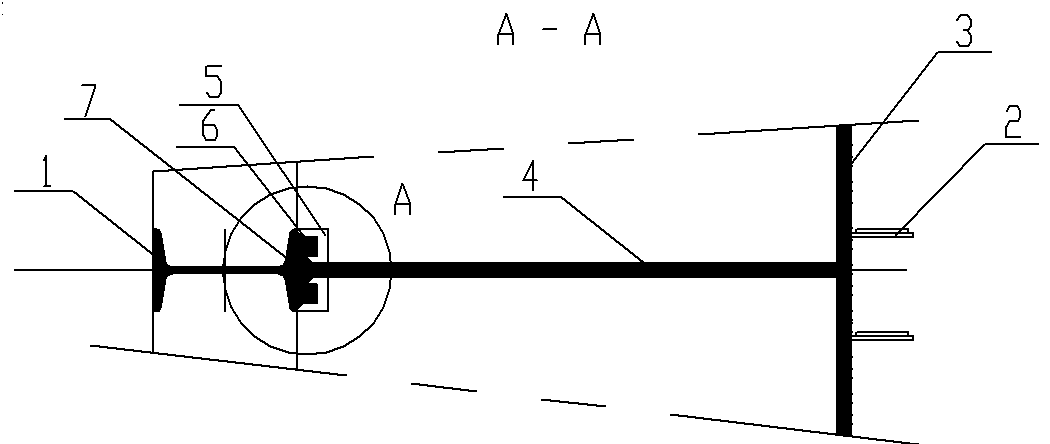

[0014] See figure 1 , figure 2 , image 3 , Figure 4 As shown, a suspension bracket structure for a boiler superheater, which includes a guard plate 1 and a superheater pipe clamp 2, the superheater pipe clamp 2 is welded to one end of a support rib 4 through a vertical plate 3, and the support rib 4 is T-shaped rib, one end is a T-shaped head, base plate 5 is installed on the guard plate 1, the side of the T-shaped head one end of the support rib 4 is close to the vertical rib 7 of the guard plate 1, and the bottom surface is supported on the upper end surface of the base plate 5, with In order to transmit the vertical load of the supporting rib plate 4, two angular hook plates 6 arranged on both sides of the T-shaped head and close to the T-shaped head are installed on the bottom plate 5 to transmit the eccentric bending moment of the supporting rib plate 4. 6 is welded to the vertical rib 7 of the guard plate 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com