Micro-channel pipeline heat exchanger and electric motor coach heat pump air conditioning system

A micro-channel and heat exchanger technology, applied in vehicle parts, heat exchange equipment, air treatment equipment, etc., can solve the problems of unfavorable heat exchange condensate removal, large flow resistance, etc., and achieve the effect of avoiding electrical corrosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

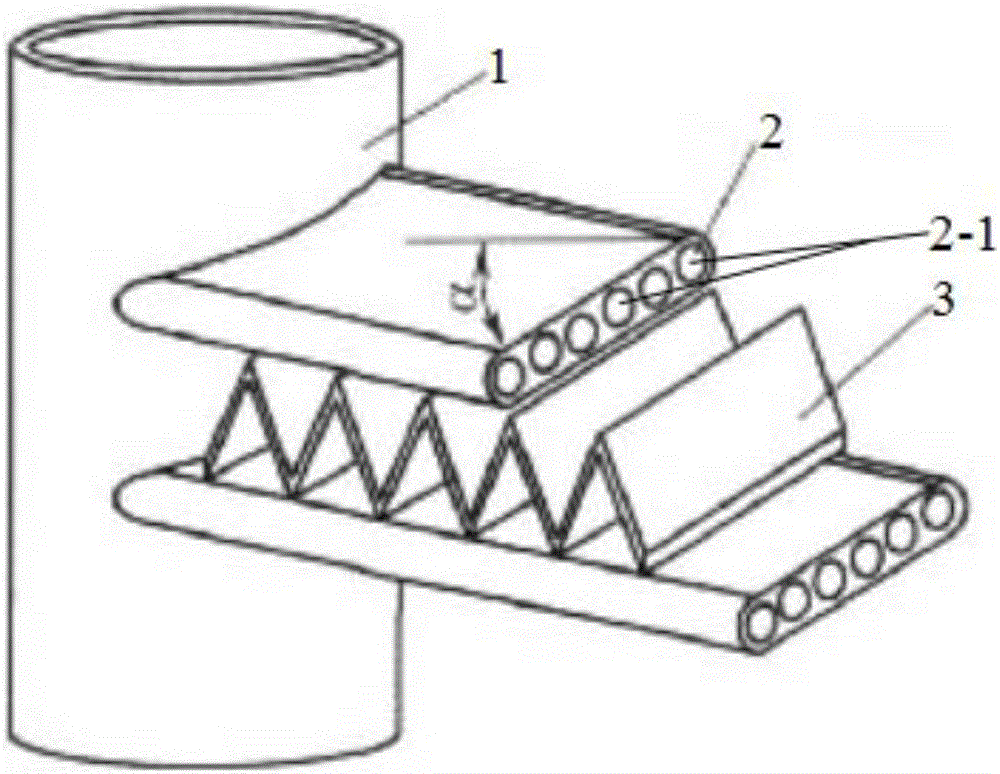

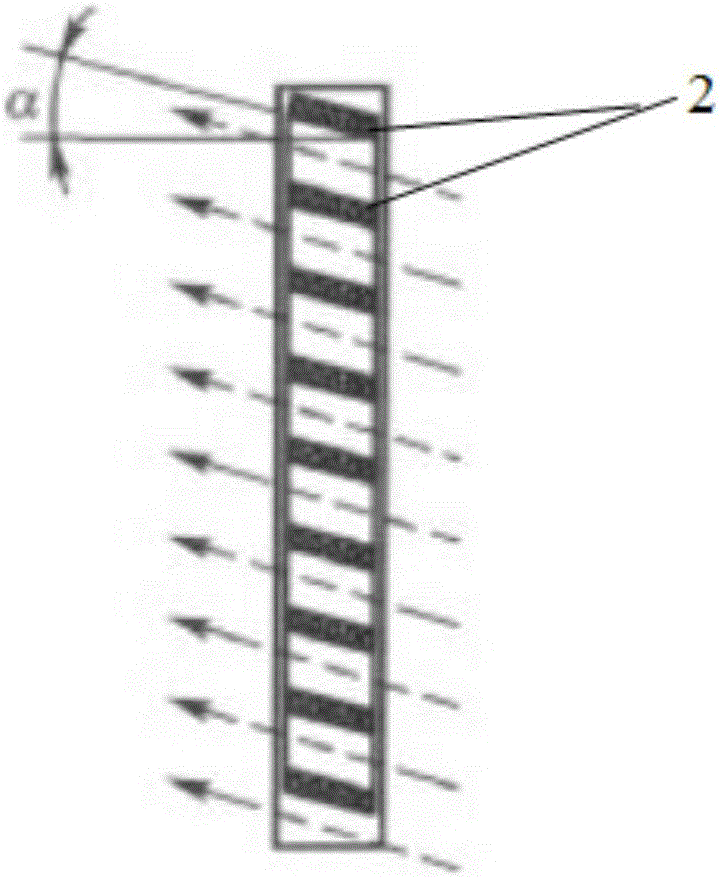

[0015] A micro-channel heat exchanger is composed of a header 1, a micro-channel flat tube 2 and fins 3, the header 1 is a round tube with both ends closed and hollow, and the micro-channel flat tube 2 is The linear type is provided with microchannels 2-1 arranged in a linear array inside it, and the fins 3 are in the shape of regular broken lines; the microchannel flat tubes 2 are welded in a manner of overlapping up and down and equidistant Between the headers 1 , the microchannel flat tubes 2 are at an angle of 30-45 degrees to the horizontal plane; the fins 3 are welded between the microchannel flat tubes 2 .

[0016] Preferably, the equivalent diameter of the microchannel 2-1 is between 1.5-2.8mm.

[0017] Preferably, the microchannel 2-1 communicates with the hollow cavity of the manifold 1 .

[0018] Preferably, the material of the header 1 , microchannel flat tube 2 and fins 3 is aluminum.

[0019] A heat pump air-conditioning system for an electric passenger car inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com