Inkjet recording ink

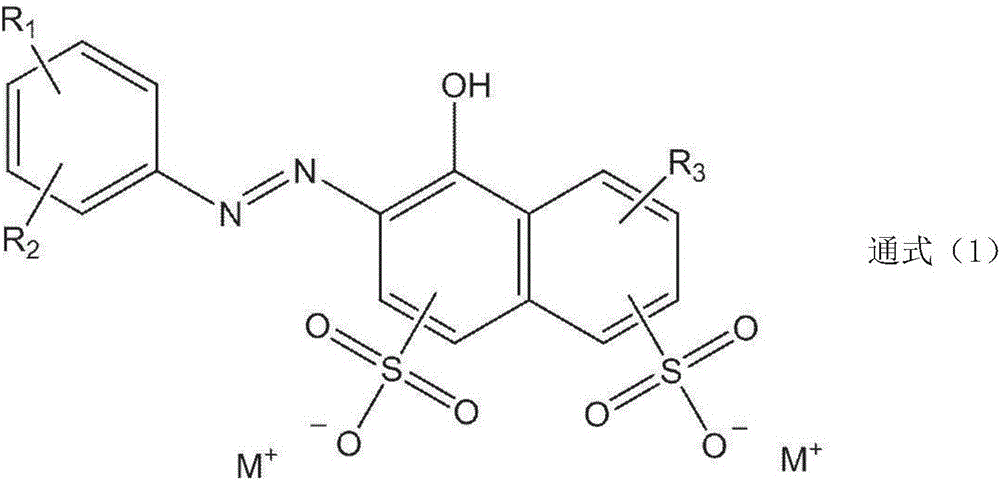

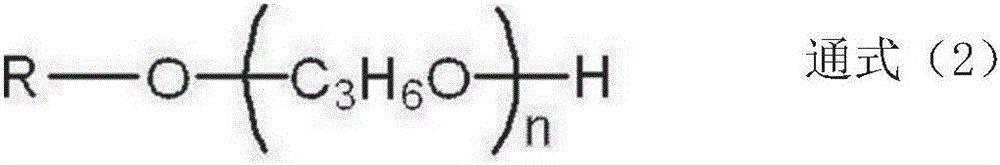

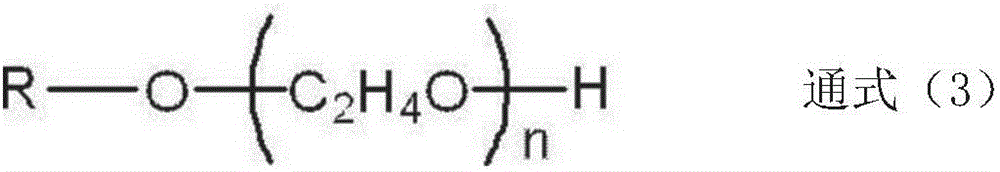

一种喷墨记录、油墨的技术,应用在油墨、应用、家里用具等方向,能够解决丧失商品价值等问题,达到喷出性优异、透印抑制的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0209]

[0210] After mixing the components of the following composition, the resulting solution was stirred at normal temperature (25° C.) for 1 hour, and the resulting solution was passed through a membrane filter with a pore size of 0.22 μm to remove coarse particles, thereby preparing Ink 1 .

[0211] -Composition of Ink 1-

[0212]

[0213]

[0214] The viscosity of the prepared ink 1 was 6.5 mPa·s (25° C.), and the surface tension was 39 mN / m (25° C.).

[0215] The viscosity and the surface tension were measured using VISCOMETER TV-22 (manufactured by TOKI SANGYO CO. LTD.) and Automatic Surface Tensiometer CBVP-Z (manufactured by Kyowa Interface Science Co., LTD.), respectively.

Embodiment 2~ Embodiment 21、 comparative example 1~ comparative example 6

[0217] Examples 2 to 21, Comparative Examples 1 to 6 The blending amounts of dyes, specific organic solvents, and other organic solvents in the ink 1 of Example 1 were changed to the blending amounts shown in Tables 2 to 4 below. , except that the ink was prepared in the same manner as in Example 1. And, the viscosity and surface tension of each prepared ink were measured by the said method. The measurement results are shown in Tables 2 to 4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com