Aqueous pigment dispersion liquid and aqueous pigment inkjet ink using same

A technology of water-based pigments and pigment dispersants, applied in the direction of pigment slurry, application, ink, etc., can solve the problem of color concentration, that is, the reduction of color rendering, and achieve the effects of high refractive index, high light resistance, and high chroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0065] (Preparation method of water-based pigment dispersion)

[0066] The aqueous pigment dispersion of the present invention can be prepared, for example, by mixing and dispersing a pigment, a pigment dispersant, an aqueous organic solvent, and water by a conventionally known method. A disperser can be used for mixing and dispersing the components. Specific examples of the dispersing machine include kneading machines, two-roll mills, three-roll mills, trade name "MIRACAL KCK" (manufactured by Asada Iron and Steel Co., Ltd.); ultrasonic dispersers; high-pressure homogenizers (trade name The product name is "Mizufluidizer" (manufactured by MIZUHO INDUSTRIAL CO.,LTD.), the product name is "Nanomizer" (manufactured by Yoshida Kikuyo Co., Ltd.), the product name is "Starburst" (manufactured by Sugino Machine Ltd.), the product name is "G-Smasher" ( RIX Corporation)) etc. In addition, ball mills, sand mills, horizontal media mill dispersers, colloid mills, etc. using bead media ...

Embodiment

[0079] Hereinafter, although this invention is demonstrated concretely based on an Example, this invention is not limited to these Examples. In addition, "part" and "%" in an Example and a comparative example are a mass standard unless otherwise indicated.

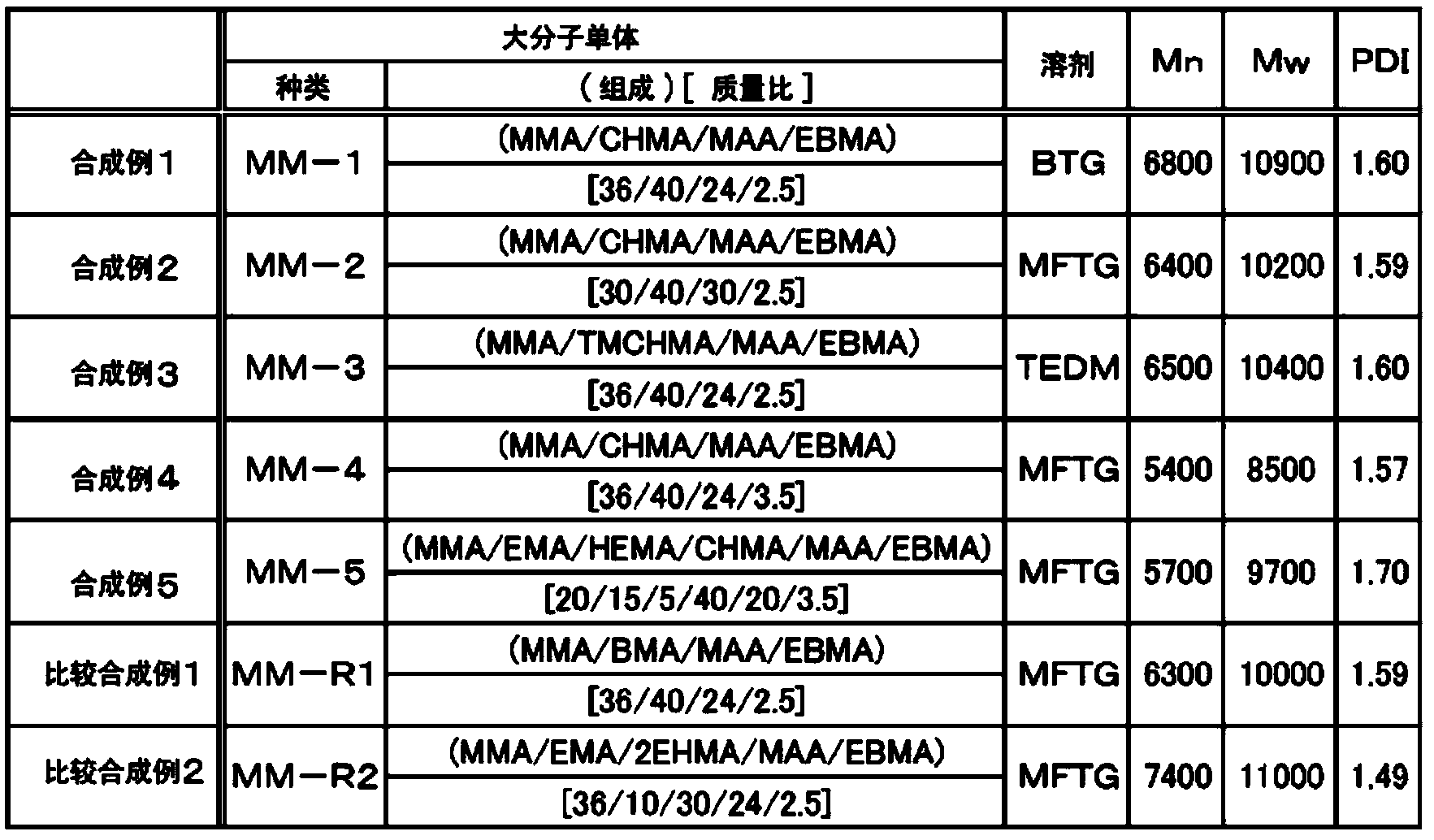

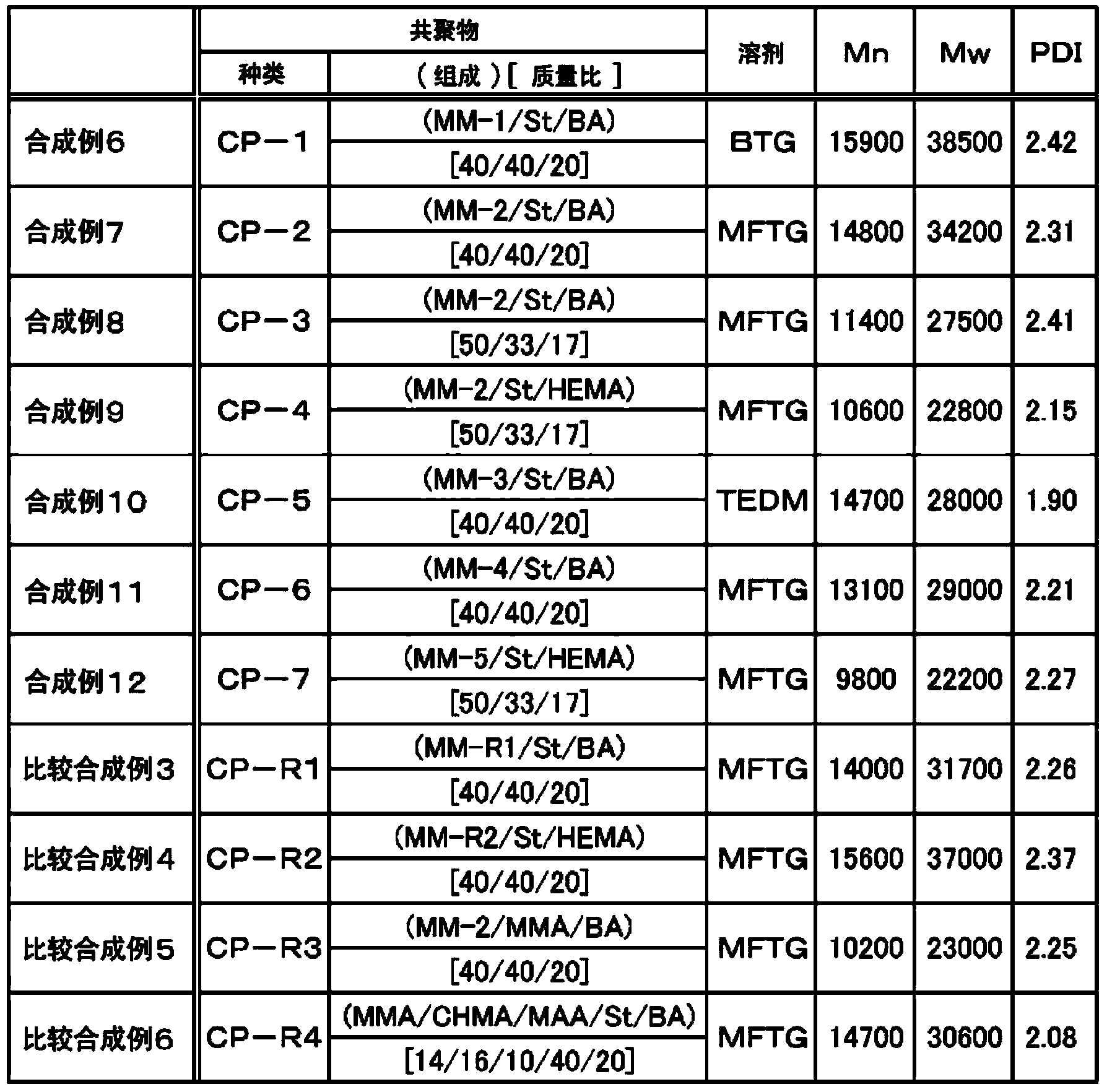

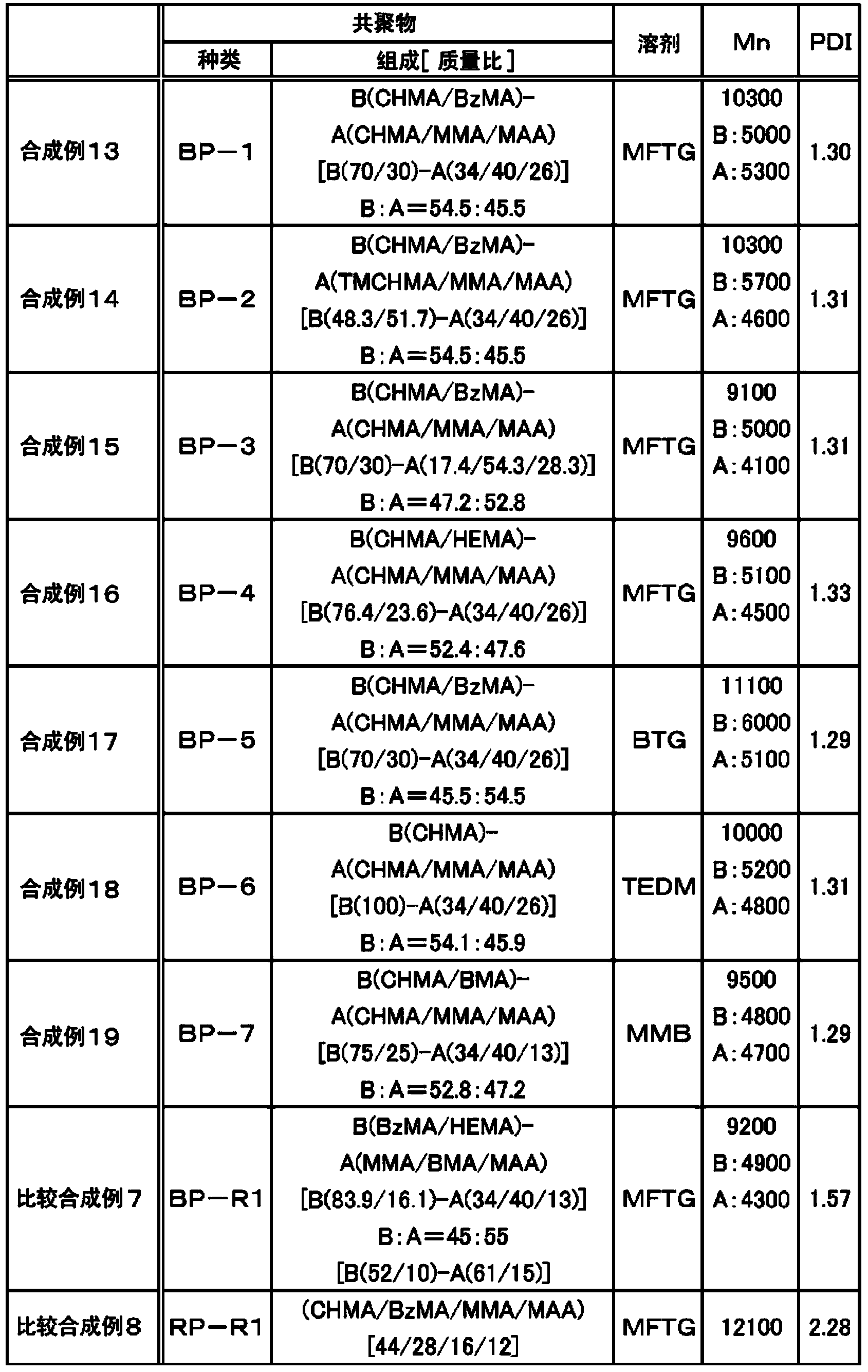

[0080] [Synthesis of Macromonomer]

Synthetic example 1

[0082] 500 parts of triethylene glycol butyl ether (hereinafter referred to as "BTG") and methyl methacrylate (hereinafter referred to as "MMA") were charged into a reaction vessel equipped with a stirrer, a reflux condenser, a thermometer, and a nitrogen gas introduction tube. 72 parts, 80 parts of cyclohexyl methacrylate (hereinafter referred to as "CHMA"), 48 parts of methacrylic acid (hereinafter referred to as "MAA"), ethyl-2-(α-bromomethyl)acrylate ( 5 parts of 2,2'- azobis (isobutyric acid) dimethyl esters (hereinafter referred to as "EBMA") (hereinafter referred to as "V-601") 2 parts. After polymerization at 75° C. for 3 hours while bubbling nitrogen gas, 1 part of V-601 was added. Further, polymerization was carried out for 4.5 hours to obtain a polymer solution containing a polymer (macromonomer MM-1). The obtained polymer solution was sampled to measure the solid content concentration, and the polymerization conversion rate was calculated as 100% in terms of non-v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com