Anti-drift core and anti-bending core bone for sand core of volute castings

A core-bone and casting technology, which is applied to the use of core-bone in sand core casting, to prevent sand core cracking, solve core drift and fracture, and simplify on-site operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

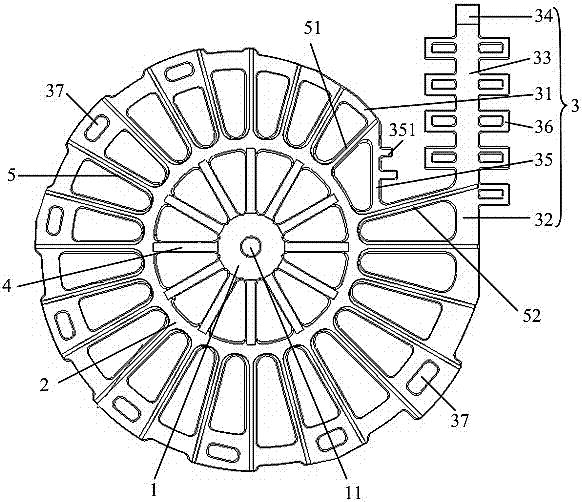

[0013] In order to more clearly illustrate the technical solutions of the embodiments of the present invention, the following will briefly introduce the accompanying drawings that need to be used in the embodiments. Obviously, the accompanying drawings in the following description are some embodiments of the present invention. Ordinary technicians can also obtain other drawings based on these drawings on the premise of not paying creative work.

[0014] see figure 1 , the embodiment of the present invention provides an anti-floating core anti-bending mandrel for sand cores of volute castings, including an inner core bone backbone 1, a middle core bone backbone 2, an outer core bone backbone 3, and a first connecting rib 4. The second connecting rib 5.

[0015] The inner core bone backbone 1, the middle core bone backbone 2, and the outer core bone backbone 3 are concentric circular structures with gradually increasing radii, and several first connecting ribs 4 are connected b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com