Full-automatic intelligent mechanical arm and working method thereof

A robotic arm and fully automatic technology, applied in the field of production and manufacturing, can solve problems such as product quality impact, mechanical arm damage, and production inconvenience, and achieve the effects of improving safety, accuracy, and applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

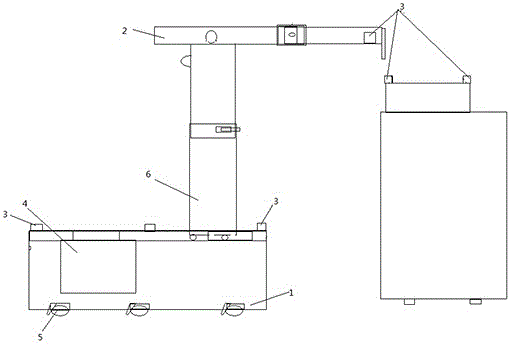

[0033] Such as figure 1 A fully automatic intelligent mechanical arm shown includes: a base 1, a shaft joint 2, a position detection device 3 and a control device 4, wherein the base 1 is provided with a bottom wheel 5, and the control device 4 There are driving mechanism, position control mechanism, sliding control mechanism, alarm mechanism and central control mechanism, and also include network connection device;

[0034] The relationship between the above components is as follows:

[0035] The shaft joint 2 is connected to the base 1 through a column 6, and the column 6 is slidably connected to the base 1, and the position detection device 3 is provided with two sets of position sensors, and the set of position sensors The sensor is located on the base 1, and another group of position sensors is located on the production line; the base 1 and the column 6 are all connected by a driving mechanism, and the two groups of position sensors are connected with a position control ...

Embodiment 2

[0043] The mechanical arm in the working method of a fully automatic intelligent mechanical arm described in this embodiment has the same structure as that in Embodiment 1.

[0044]A fully automatic intelligent mechanical arm as shown in the figure includes: a base 1, a shaft joint 2, a position detection device 3 and a control device 4, wherein the base 1 is provided with a bottom wheel 5, and the control The device 4 is provided with a driving mechanism, a position control mechanism, a sliding control mechanism, an alarm mechanism and a central control mechanism, and also includes a network connection device;

[0045] The relationship between the above components is as follows:

[0046] The shaft joint 2 is connected to the base 1 through a column 6, and the column 6 is slidably connected to the base 1, and the position detection device 3 is provided with two sets of position sensors, and the set of position sensors The sensor is located on the base 1, and another group of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com