Electromobile four-gear manipulator

A technology of electric vehicle controller and manipulator, which is applied in the direction of vehicle components, transmission control, components with teeth, etc., can solve the problems of inconvenient installation and uncompact structure, and achieve the effect of preventing driving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

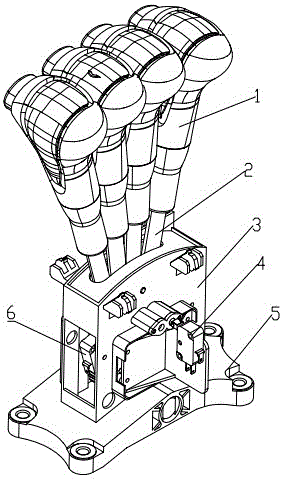

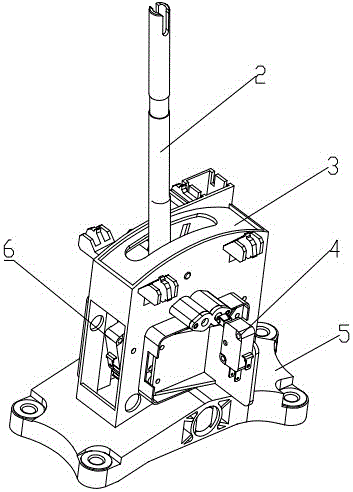

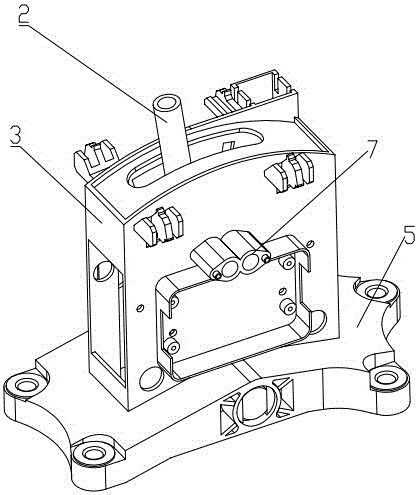

[0023] Embodiment one: if figure 1 As shown, the present invention discloses a four-speed manipulator for an electric vehicle, including a base 5, a housing 3, a main shaft, a gear lever 2, a handle 1 and a shift signal generating device, and the housing 3 is fixedly mounted on the top of the base 5 On the surface, a rectangular gap is set in the middle of the base 5, and the main shaft is horizontally set in the rectangular gap and is fixedly connected with the base 5. The top surface of the housing 3 is provided with an arc-shaped slot 2-2, and the arc-shaped slot 2 The axis of rotation of -2 is parallel to the axis of the main shaft, the stop rod 2 passes through the arc-shaped long slot hole 2-2 on the top surface of the housing 3, and the sleeve 2-6 provided at the lower end of the stop rod 2 is set on the outside of the main shaft, and the stop rod 2 The handle 1 is fixedly installed on the top of the rod 2 , and a shift signal generating device is arranged between the g...

Embodiment 2

[0031]Embodiment 2: The difference between this embodiment and Embodiment 1 is only the shift signal generating device. The shift signal generating device in Embodiment 1 is a mechanical structure, while the shift signal generating device in this embodiment is electronic. Type structure, which includes a magnet installed in the middle of the stop rod and a circuit board installed outside the housing. The circuit board is equipped with four sets of reed switches that are evenly distributed around the axis of the main shaft. The four sets of reed switches are aligned with the axis of the main shaft. The distance is equal to the distance between the magnet and the axis of the main shaft, and the signal output end of the circuit board is connected to the electric vehicle controller.

[0032] In the specific application process of this embodiment, the blocking rod can only stay in four different positions due to the function of the limit device during the swing process. When it is l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com