Reusable sealant tip nozzle connecting ring

A connecting ring and rubber tip technology, which is applied in the field of sealant tip connecting rings, can solve the problem that the tip cannot be used repeatedly, and achieve the effects of easy rotation, removal of residual air, and increased contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

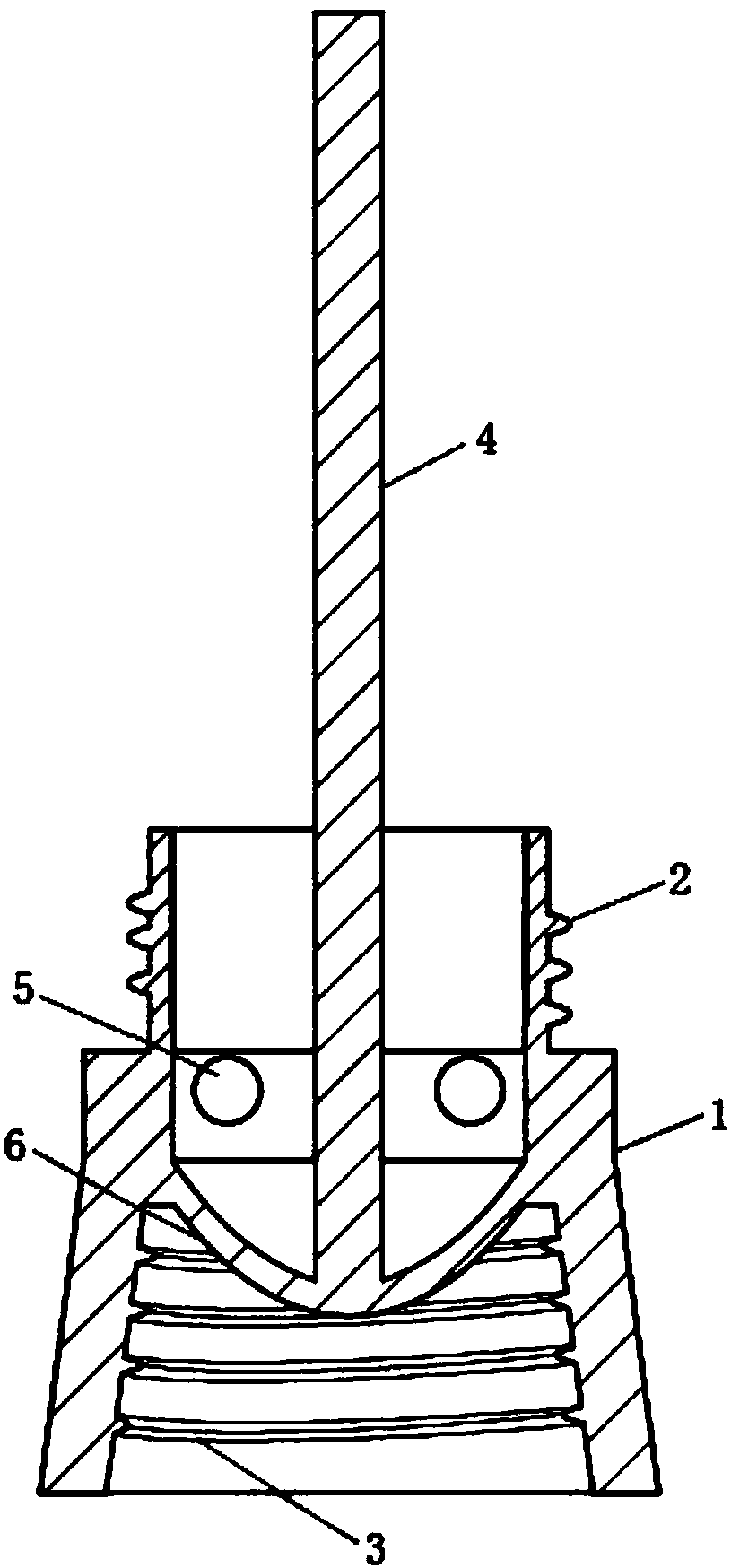

[0011] The present invention will be further described now in conjunction with accompanying drawing.

[0012] see figure 1 , figure 1 Shown is an embodiment of the present invention, including a connecting ring body 1, and also includes an upper external thread 2, a lower internal thread 3 and a central rod 4, wherein the upper half and the lower half of the connecting ring body 1 are separated, and the upper outer thread The thread 2 is connected with the sharp mouth of the sealant, and the bottom internal thread 3 is connected with the bottle mouth of the sealant hose. The central rod 4 is placed in the center of the beak, and the central rod 4 extends upward from the connecting ring body. After the sealant in the tip is cured, it will be entangled around the central rod 4 of the connecting ring, and the hardened gel can be separated from the wall of the tip as long as it is easily unscrewed, which is convenient for the second reuse of the tip; if the hardened inside the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com