Belt calibrating device of asphalt paver

A correction device and paver technology, applied in the direction of conveyor objects, transportation and packaging, roads, etc., can solve problems such as deviation, tearing, and production impact of conveyor belt glued to ensure normal operation and adaptability The effect of strong ability and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

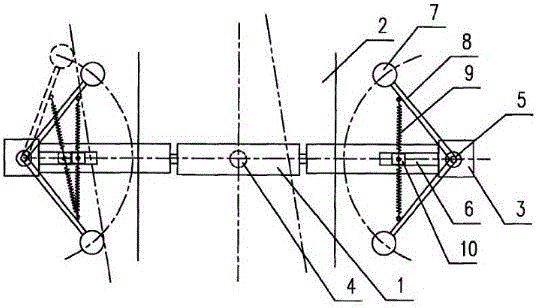

[0011] See figure 1 , asphalt paver belt correction device, including idler 1, belt 2, idler bracket 3, idler bracket rotation fulcrum 4, the two ends of idler bracket 3 are provided with rotating shaft 5 and slideway 6, and the two slideways 6 are arranged opposite to each other , the two stop rollers 7 are connected to the rotating shaft 5 through the connecting rod 8, and the connecting rod 8 is connected to the slider 10 in the slideway 6 through the spring 9. After the belt 2 deviates, the stop roller 7 is pushed, and the spring 9 is elastically Make the idler bracket 3 rotate around the fulcrum 4 of the roller bracket to correct the deviation of the belt 2. The spring 9 is used for the reset of the stop roller 7, and the deviation correction force can be adjusted.

[0012] Two stop rollers 7 are arranged before and after the idler bracket 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com