Integral built-in process for groups of anchor bolts

An anchor bolt and pre-embedded technology, applied in special foundation layout, roads, tracks, etc., can solve the problems of unsuitable pre-embedded construction, large bottom area of anchor bolts and bolt distance, poor positioning accuracy, etc., to speed up the construction speed, Simple process and the effect of improving installation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

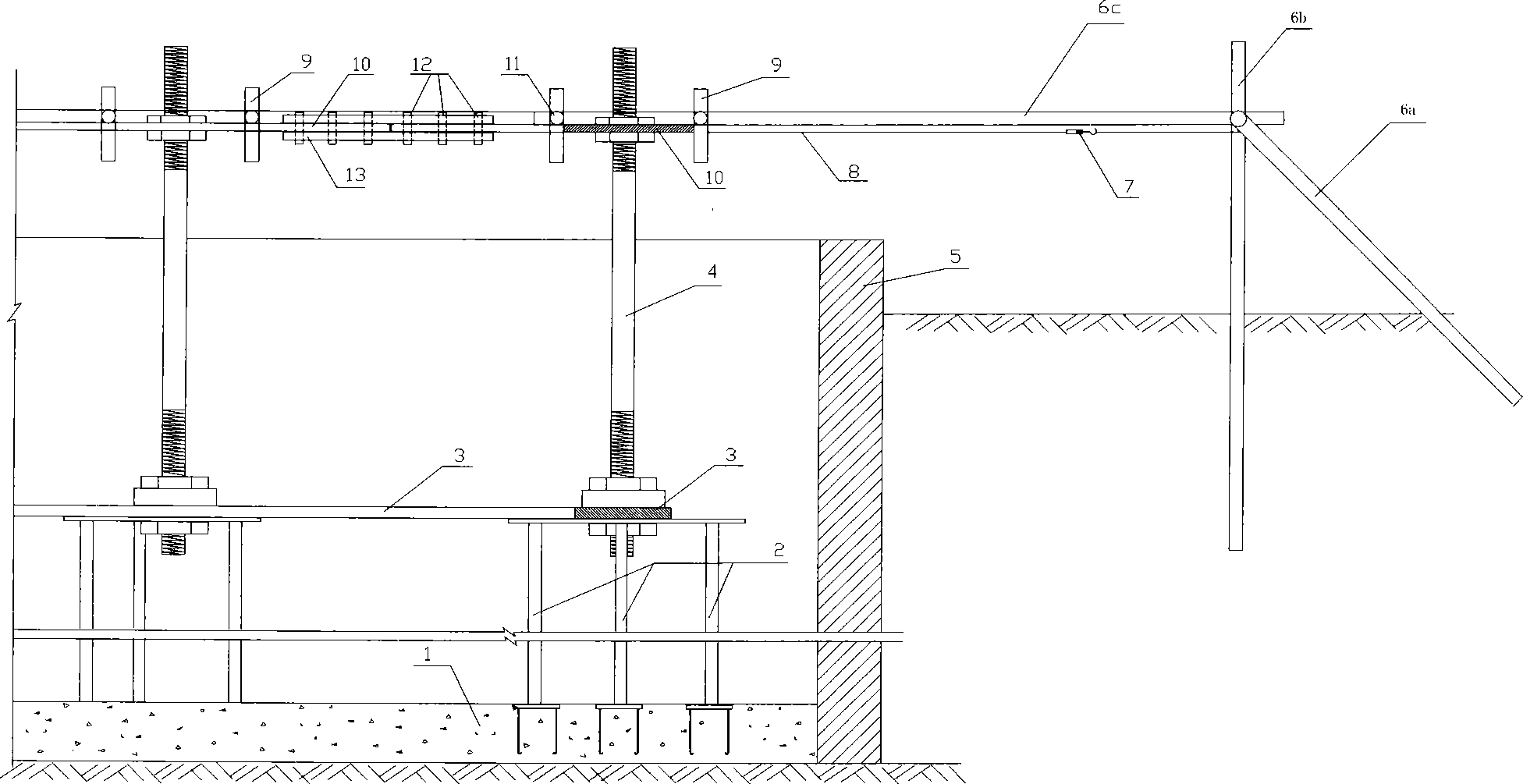

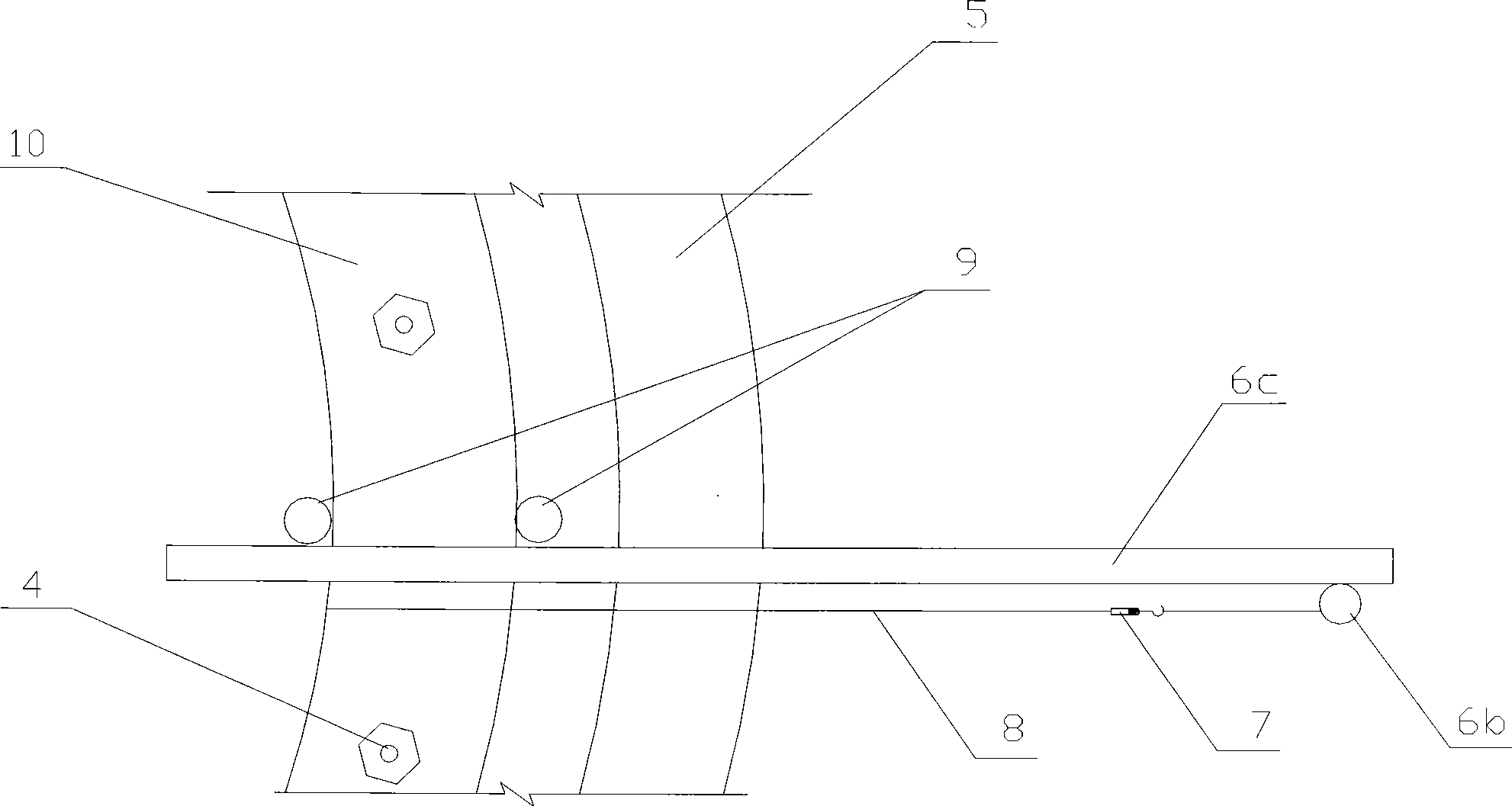

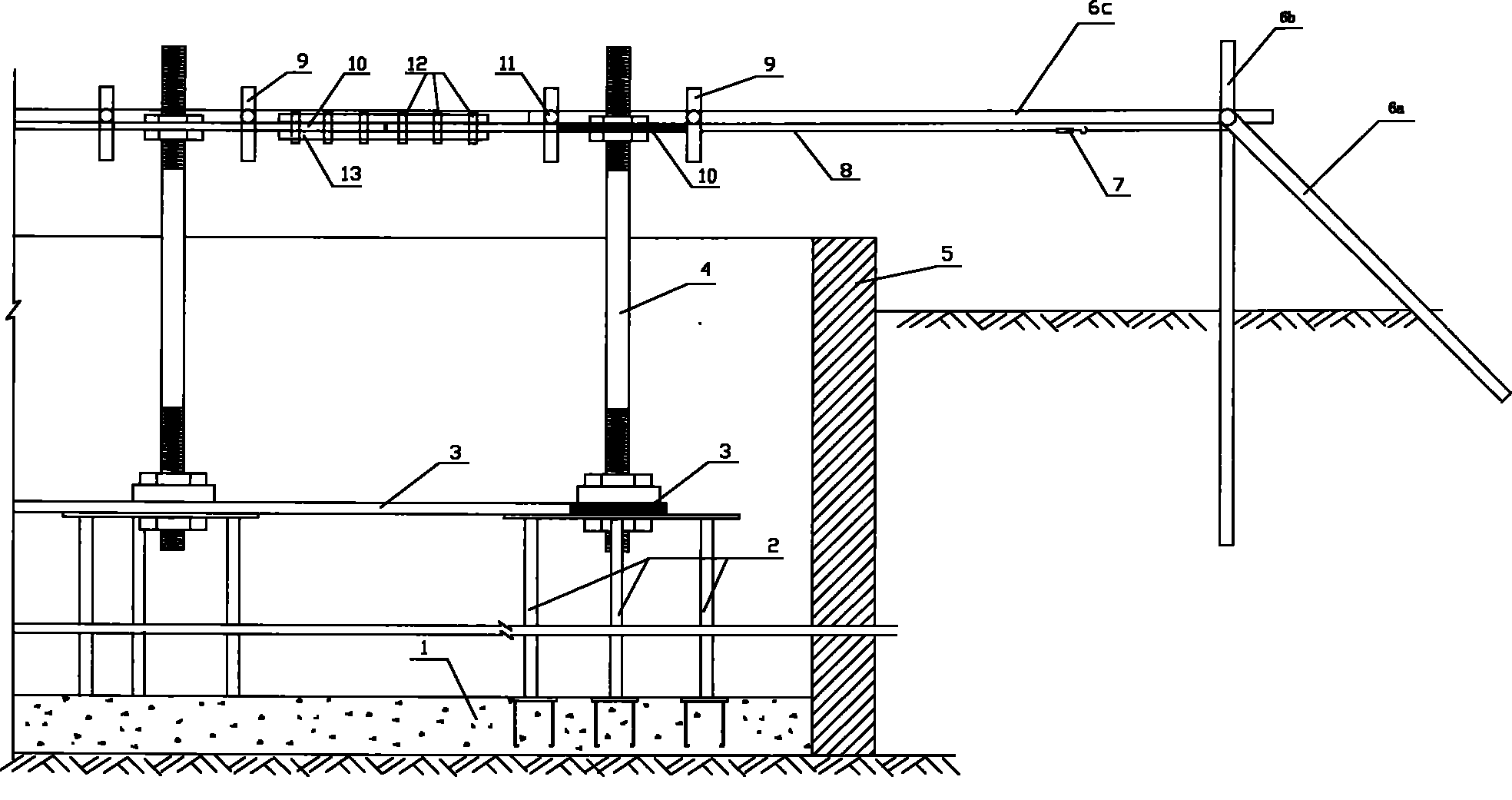

[0032] like figure 1 , figure 2 As shown, the integral pre-embedding method for group anchor bolts includes the following steps:

[0033] a. After the assembled lower positioning plate 3 is fixed on the steel bracket 2 in the base groove of the foundation outer mold 5, the lower end of the pre-embedded anchor bolt 4 is fixed on the lower positioning plate 3, and the steel bracket 2 is positioned along the bottom The plate 3 is evenly arranged in the circumferential direction, and the number and spacing are determined comprehensively by the construction design according to the type and spacing of the embedded anchor bolts 4, the weight of the upper and lower positioning plate system, the out-of-plane rigidity, the concrete pouring method and the level of the horizontal thrust. It is a column structure, its cross section is a triangular structure, the lower part of the steel bracket 2 is reliably fixed with the foundation 1, and the upper part of the steel bracket 2 is welded ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com