Vertically advance cauldron car

A technology of entering the kettle and straight rods, which is applied in the field of glass processing, can solve the problems of poor overall appearance of laminated glass products, the inability to remove the film gas, and the inability to remove the glue, so as to facilitate the reservation of gaps, eliminate bowl-shaped optical deformation, and shape beautiful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

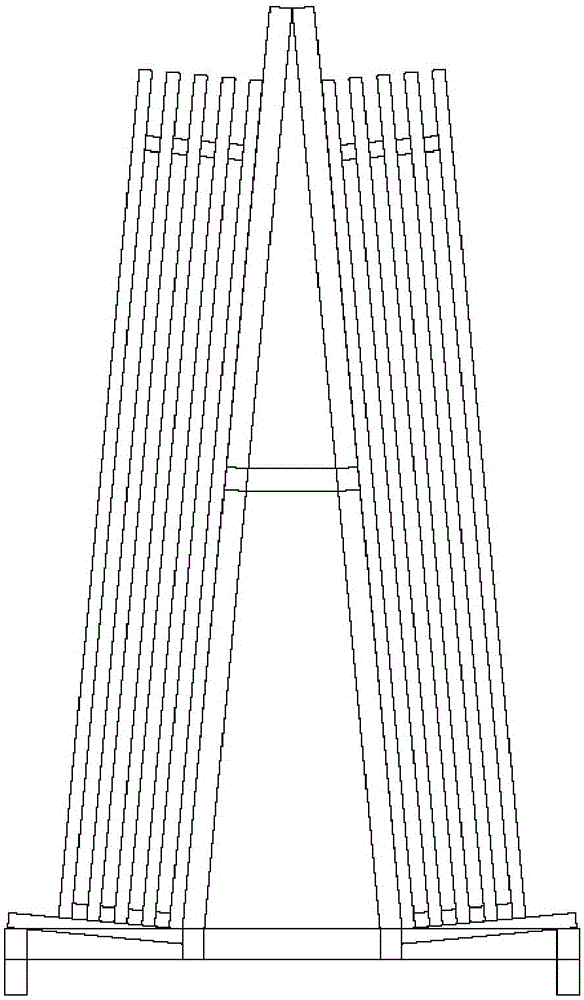

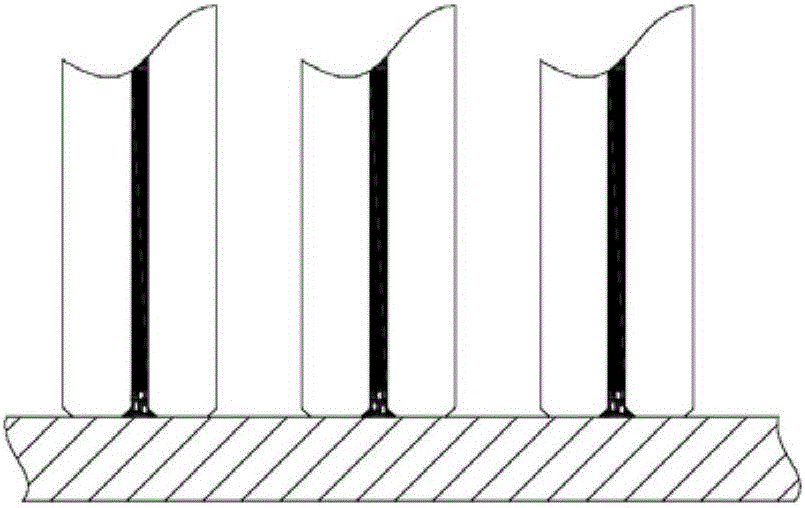

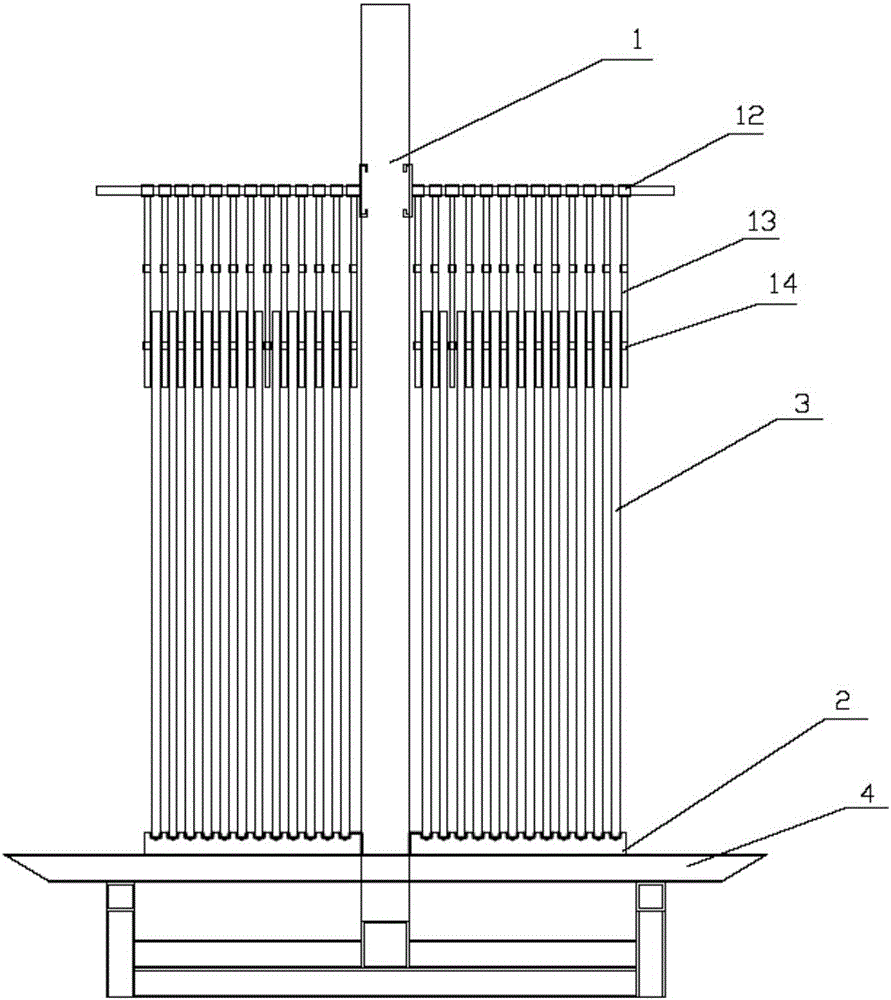

[0019] like image 3 , 4 As shown in , 5, the car that enters the kettle vertically includes a platform 4 for placing glass, and is characterized in that: a T-shaped bracket 1 is fixed on the platform 4, and square pads 2 are fixed on both sides of the bottom 1 of the T-shaped bracket. The upper surface of the cushion block 2 is provided with several parallel through grooves 21, and the middle position of the bottom of the through groove 21 is provided with a holding groove 22. The two beams above the T-shaped bracket 1 are steel pipes 11, and the steel pipes 11 are sleeved with a number of sliding parts that can slide left and right. A slide block 12, a spacer support bar 13 is fixed below the slide block 12, and a silicone tube 14 is sleeved on the support bar 13 lower ends. The supporting rod 13 hanging down from the crossbeam of the T-shaped bracket 1 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com