A microalgae scale cultivation device suitable for improving carbon sequestration efficiency

A culture device and high-efficiency technology, which is applied in the field of microalgae scale culture devices, can solve the problems of no improvement in utilization rate, difficulty in realizing large-scale culture, and increasing the depth of culture solution, so as to prevent the formation of fog film, low production cost, and smooth The effect of not being blocked

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

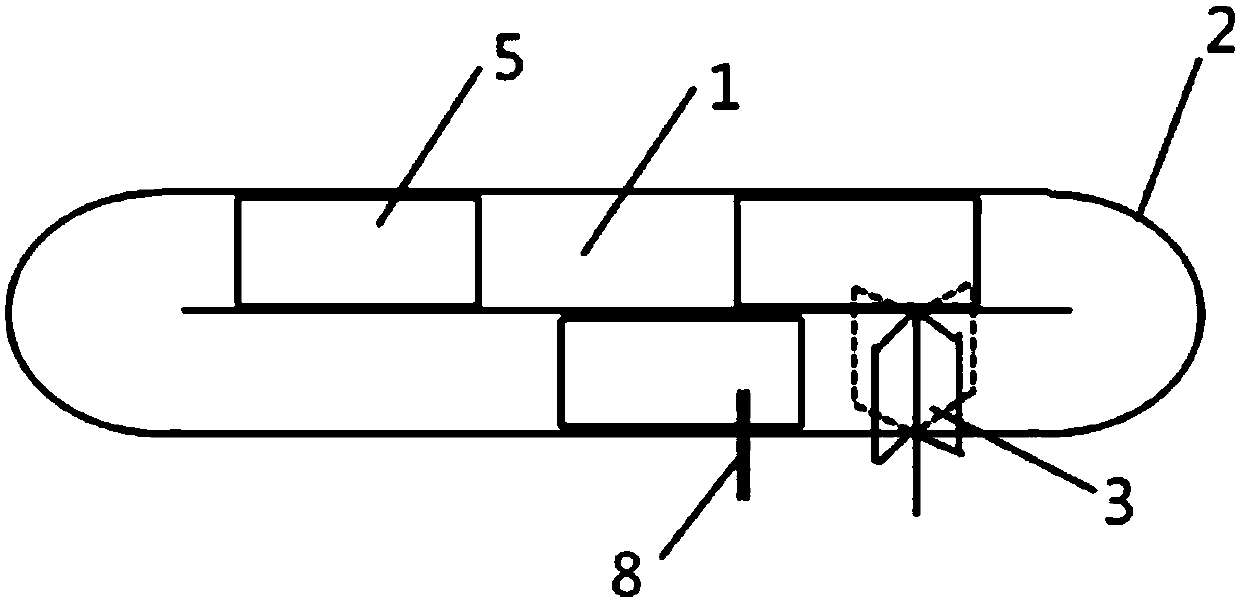

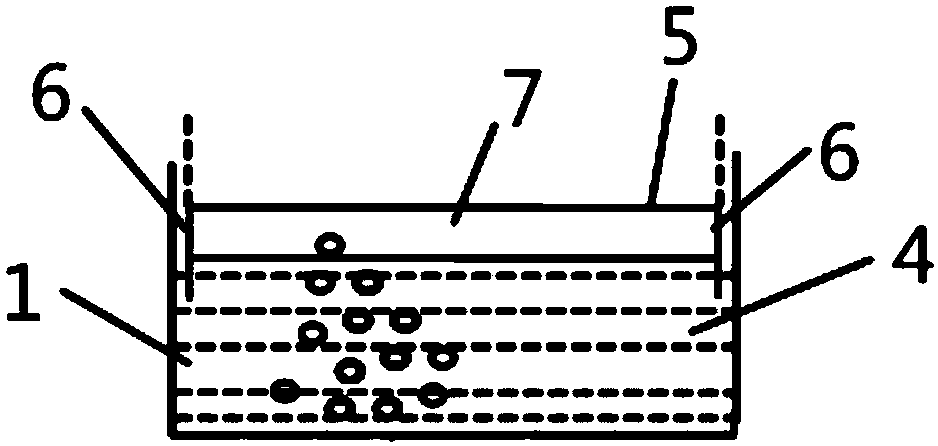

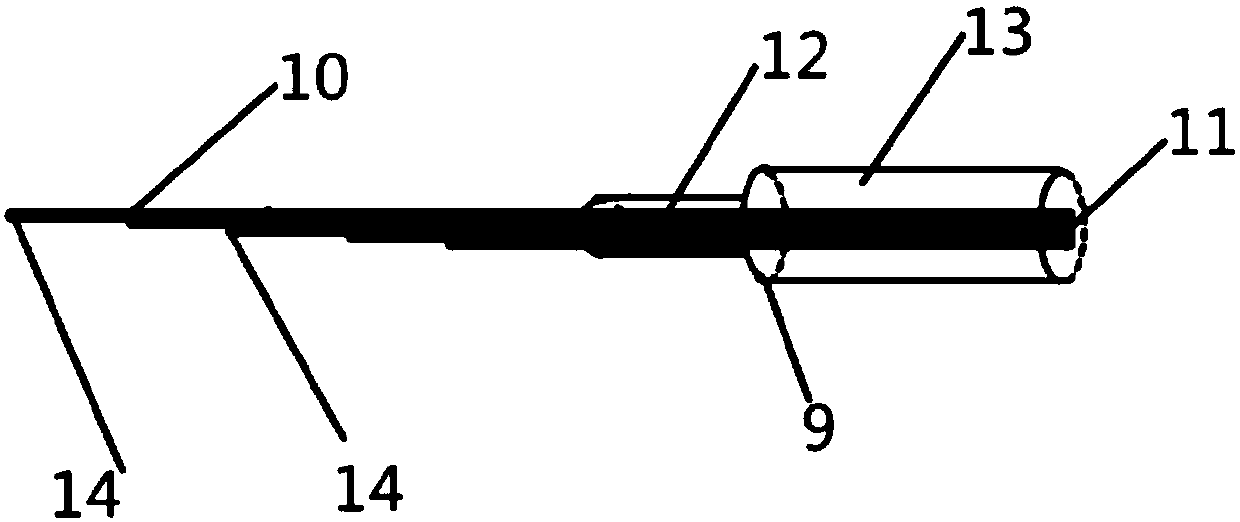

[0022] Such as figure 1 A microalgae scale culture device suitable for improving carbon sequestration efficiency as shown, comprising a runway pool 2 with at least one runway 1 and a stirring paddle 3 installed in the runway pool, the stirring paddle is installed in the runway One end of the paddle makes the algae solution 4 in the runway flow through the rotation of the stirring paddle; it also includes several transparent cover plates 5, and the transparent cover plates 5 are intermittently distributed above the runway, and the bottom of the transparent cover plate 5 Contact with the upper surface of the algae solution 4 . Such as figure 2 As shown, the transparent cover plate 5 is a rectangular transparent thin plate, and the two sides adjacent to the transparent cover plate and the side wall of the runway are each equipped with a first air-blocking strip 6, and the algae liquid inflow end of the transparent cover plate A second air-blocking strip 7 is installed, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com