Construction method of large diameter assembled steel bellows culvert

A construction method and corrugated pipe technology, which is applied in the field of culvert construction, can solve problems such as corrugated pipe culverts are easily deformed, culvert structure is unstable, and construction methods are improper, so as to improve the strength and stability, accurate and reliable construction of pipe culverts, and improve The effect of overall strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

[0026] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

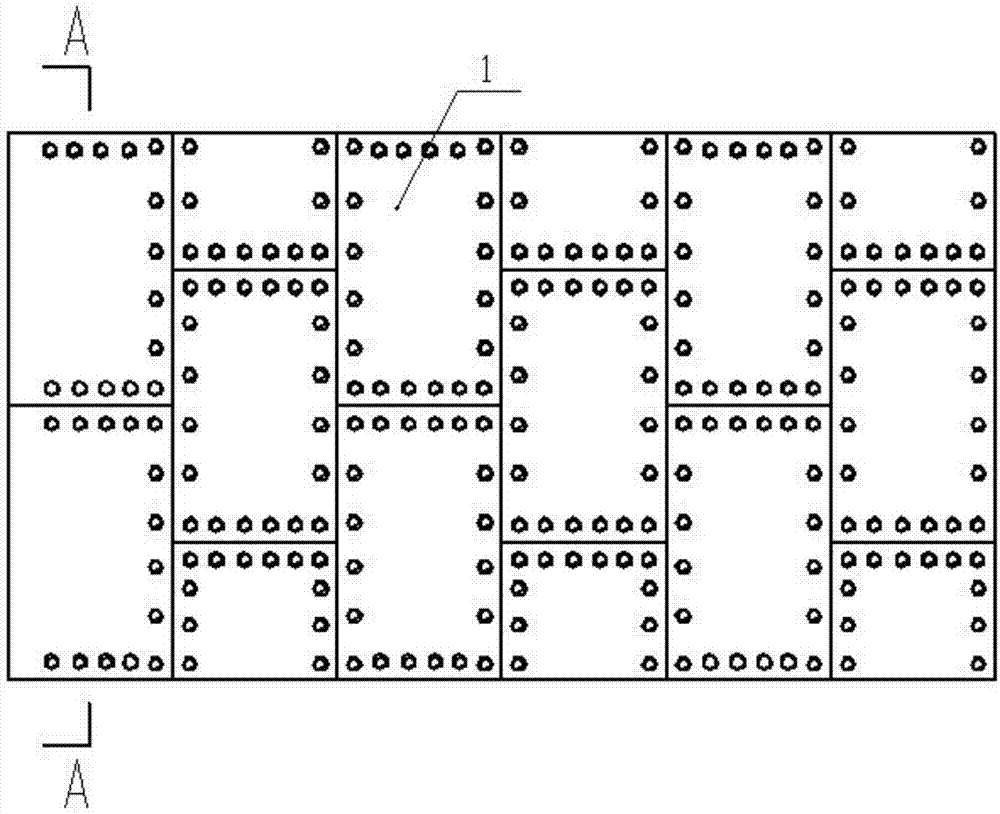

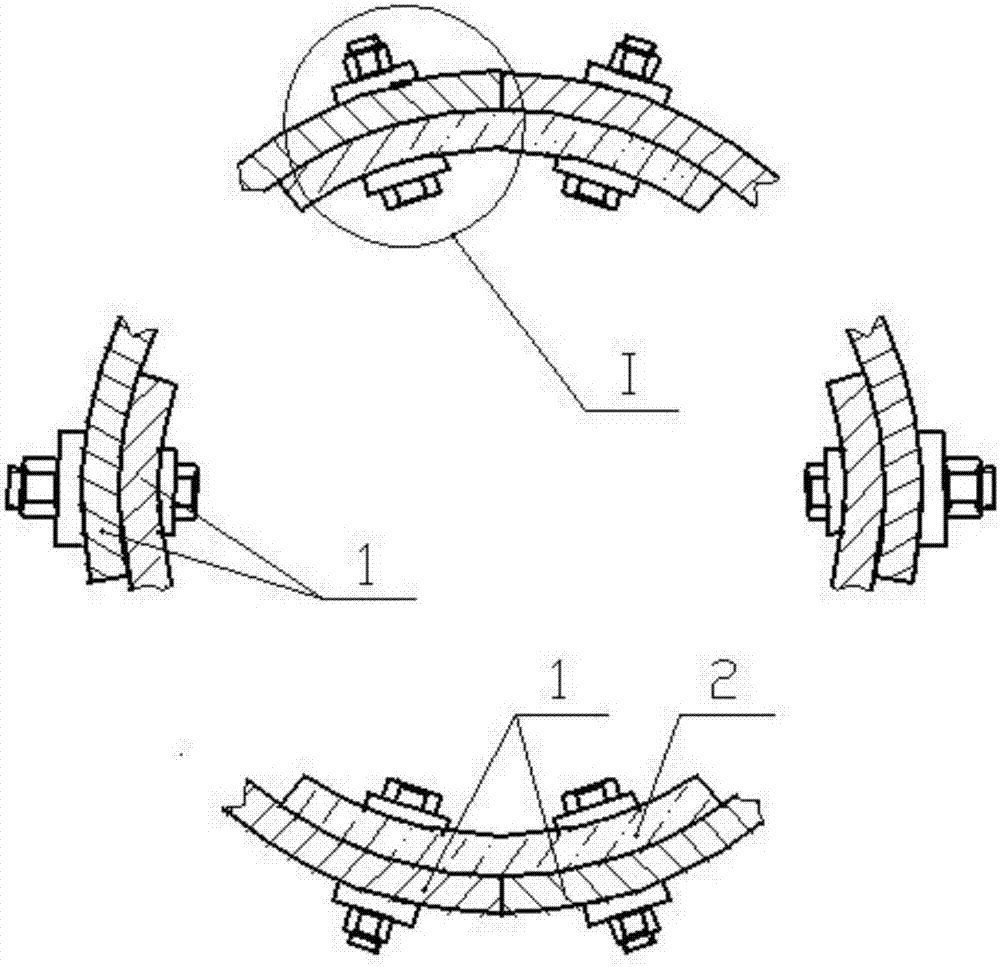

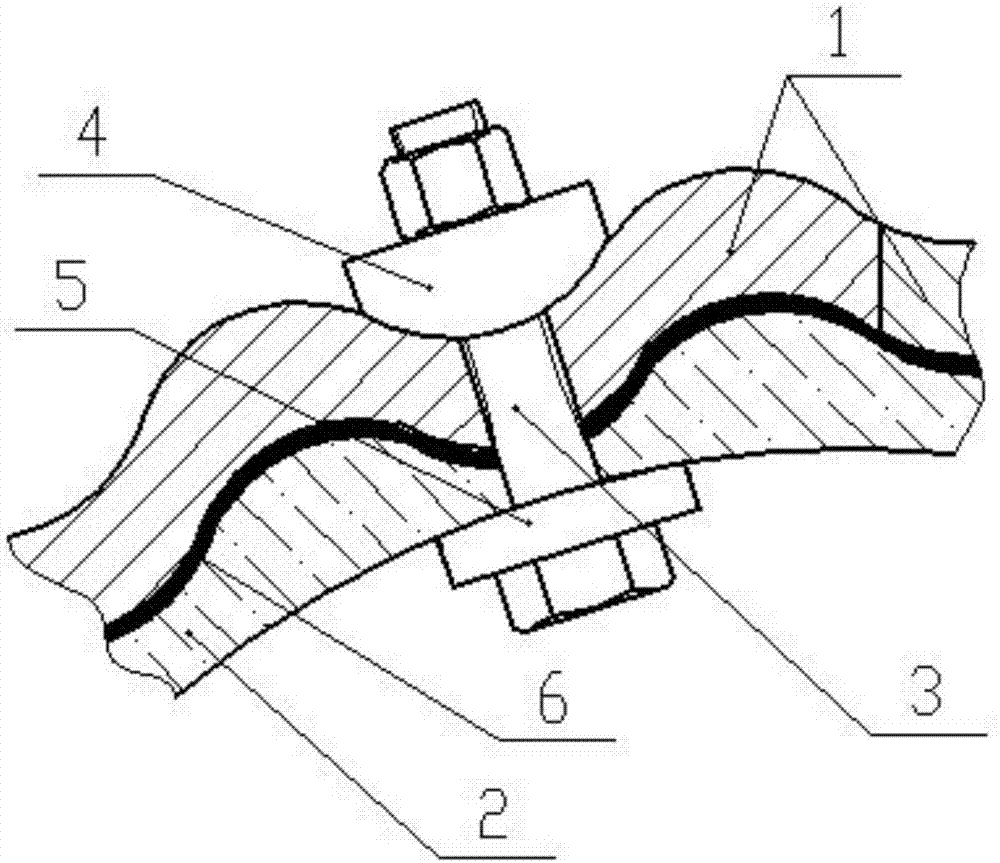

[0027] A large-diameter assembled steel bellows culvert construction method, which includes construction preparation, construction lofting, foundation pit excavation, foundation construction, steel bellows splicing and installation, steel bellows sealing and anti-corrosion treatment, and culvert back Backfill and inlet and outlet treatment. The specific construction process of the corresponding steps is as follows:

[0028] 1. Construction preparation. Clear and level the construction site, organize the required machinery and tools to enter the site, and arrange various material stacking sites. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com