Multi-point yield energy dissipating type mild steel energy dissipater

A technology of energy dissipator and mild steel, which is applied in the direction of building components, earthquake resistance, building types, etc., can solve the problems of stress concentration effect, poor deformation capacity, and easy local yield of energy dissipator, so as to improve the stress concentration effect and improve the low The effect of cycle fatigue performance and flexible layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In the following, the multi-point yield energy dissipation mild steel energy dissipator proposed by the present invention will be further described in detail with reference to the accompanying drawings and specific examples. It should be noted that the drawings all adopt a very simplified form and all use imprecise proportions, which are only used to conveniently and clearly assist in explaining the purpose of the implementation of the present invention.

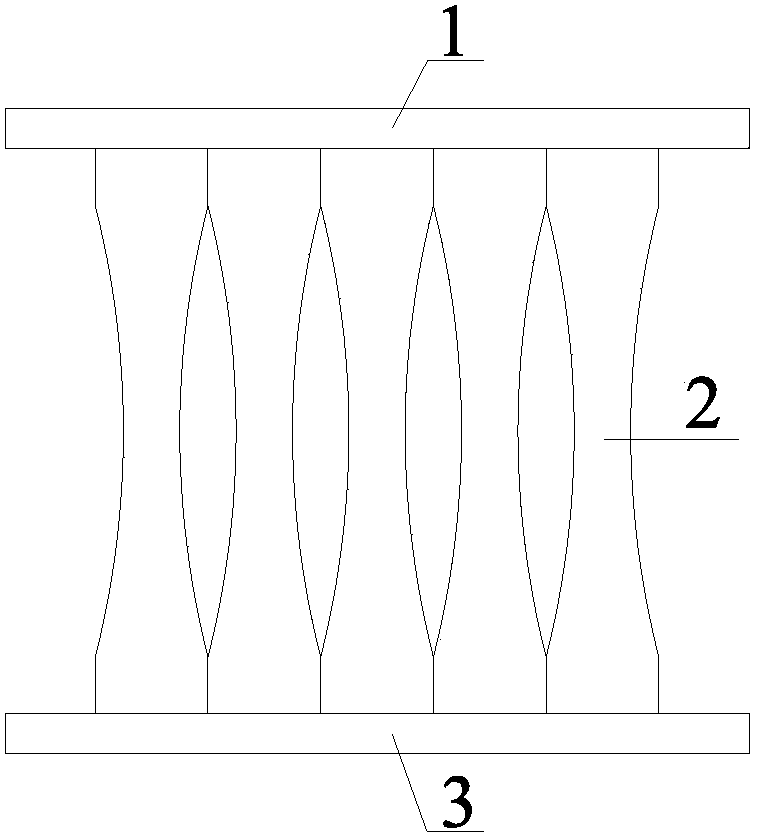

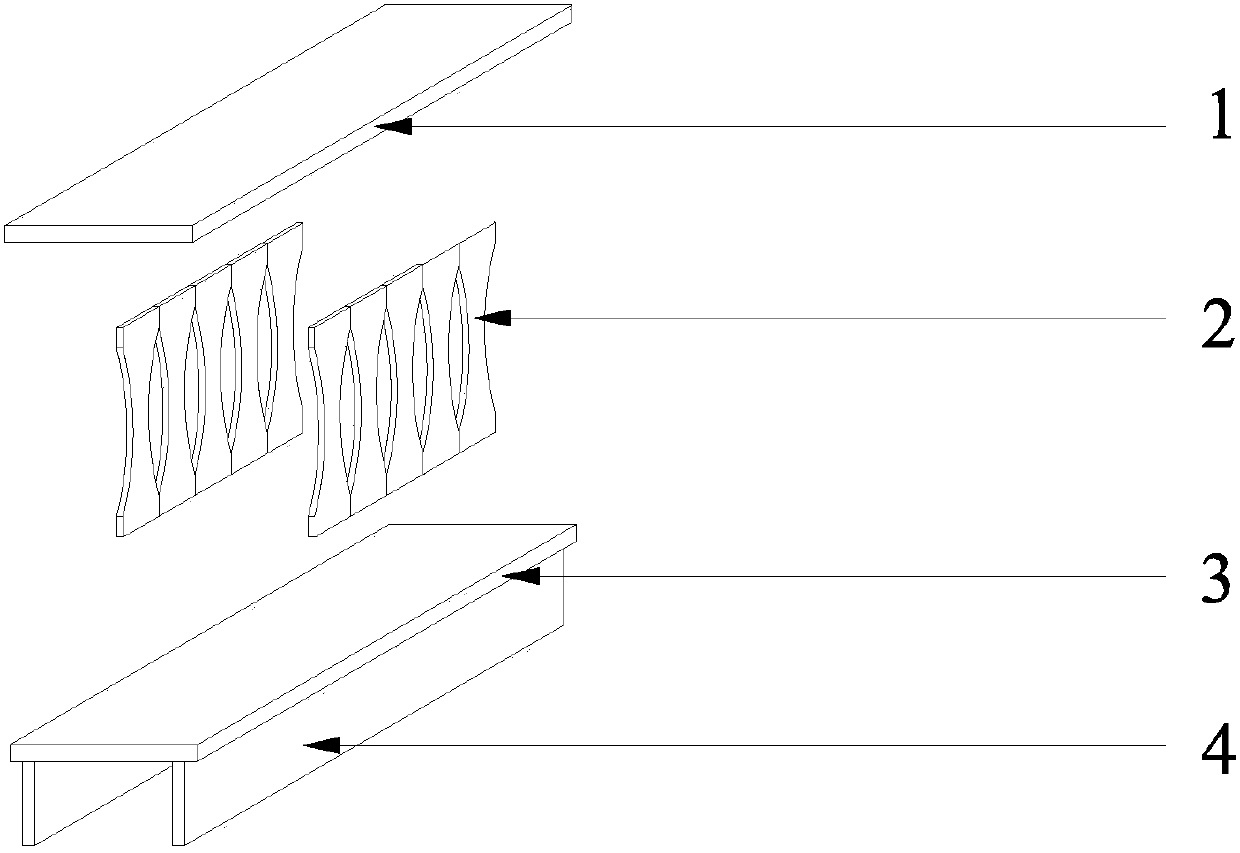

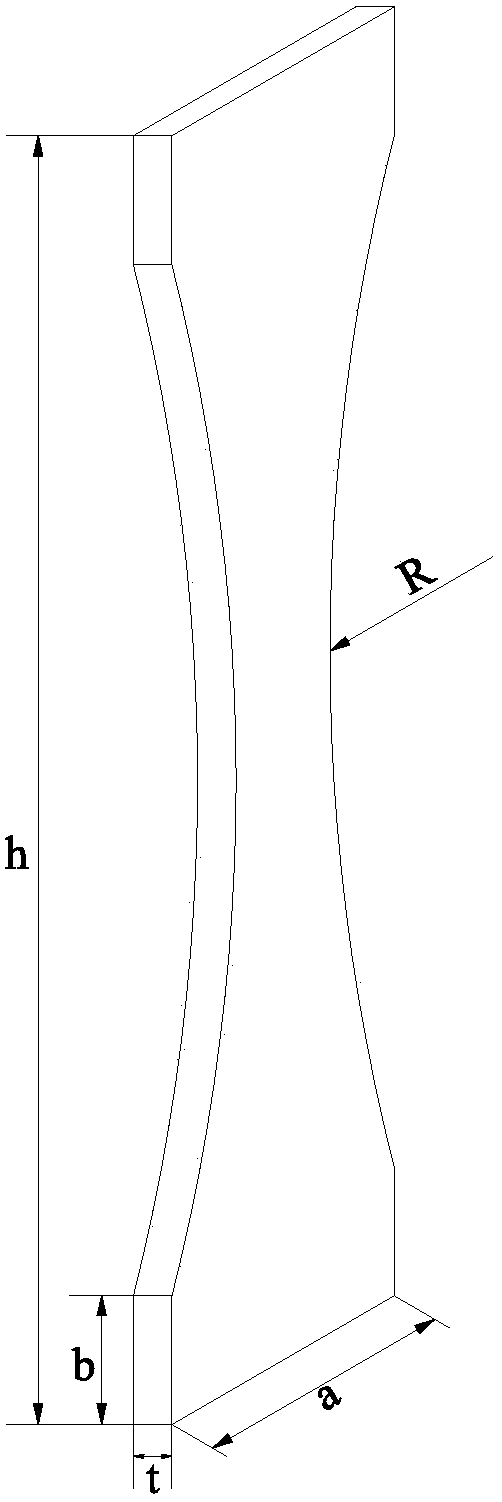

[0030] Such as figure 1 , figure 2 As shown, a multi-point yield energy dissipating mild steel energy dissipator provided by the present invention includes a top plate 1, an energy dissipating plate 2, a bottom plate 3, and a connecting plate 4. The energy dissipating plate 2 is composed of a plurality of energy dissipating units. The inner arrangement is arranged between the top plate and the bottom plate, and the connecting plate is disposed on the lower surface of the bottom plate.

[0031] Preferably, the material of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com